Compact Electric Cylinders

DR Series

- A Compact Structure That Integrates a Ball Screw and Stepper Motor

- Equipped with Closed Loop Stepper Motor

- Stroke 25/30 mm, Frame Size 20/28 mm

- Ultra-High Precision Positioning

Eigenschaften | Compact electric cylinder DR Series

Key Features

Integrated Structure of αSTEP and Ball Screw

Achieve Highly Accurate Positioning by Combining the Highly Accurate αSTEP With a Ball Screw

By integrating the hollow rotor and ball screw nut without using couplings or other connecting parts, the rigidity of the parts and the effect of backlash due to combining are reduced.

2 Types of Ball Screws for Drive

| Drive Ball Screw | Precision | Rolled |

|---|---|---|

| Repetitive Positioning Accuracy | ±0.003 mm | ±0.01 mm |

| Minimum Travel Amount | 0.001 mm | |

Achieve Large Transportable Mass and High-Speed Operation*

| Lead | 1 mm | 2.5 mm | |

|---|---|---|---|

| Transportable Mass | Horizontal | 4 kg | 4 kg |

| Vertical | 4 kg | 2 kg | |

| Maximum Speed | 40 mm/s | 100 mm/s | |

- *The specification values in the table are for the table type with frame size of 28 mm.

The shortest positioning time can be easily calculated

For applicable products of Oriental Motor's electric actuators, a support tool is available to calculate the reference positioning time according to the "model" and "operation conditions."

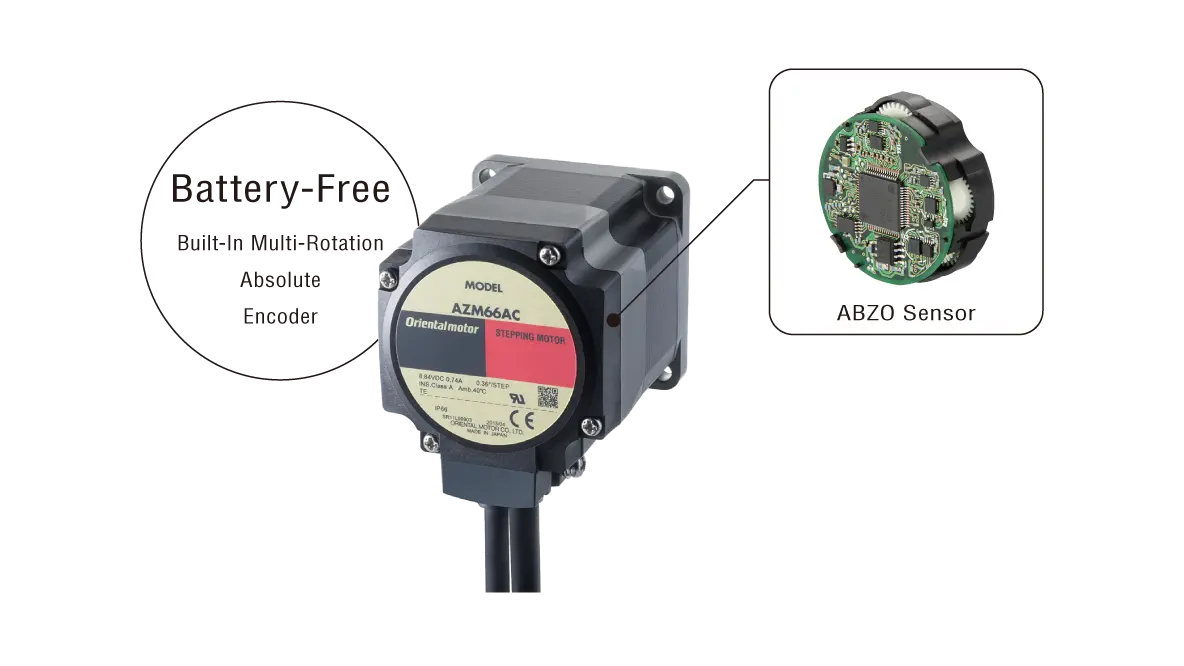

αSTEP AZ Series Drive Motor Equipped

- Features a built-in battery-free absolute encoder with no external sensors required for continuous monitoring of the motor position

- High reliability with closed loop control

- High efficiency technology reduces motor heat generation and saves energy

Allows Stable, Fine Feed

Equipped with αSTEP, which enables stable repetition of finely-detailed movements, 1 step at a time. Ideal for fine adjustment of cameras and lenses.

Smooth Low Speed Operation

The microstep drive and smooth drive function* reduce vibration at low speed and allow for smooth movement. Ideal for drive shafts that stably supply solution from a syringe.

- *The smooth drive function automatically microsteps based on the same traveling amount and traveling speed used in the full step mode, without changing the pulse input settings.

Contributes to Size and Weight Reductions of Equipment

The compact body with integrated αSTEP and ball screw can contribute to reducing equipment size and space saving.

The reduced weight at the end of the equipment is expected to increase design flexibility.

Any Combination of Types and Additional Functions is Possible.

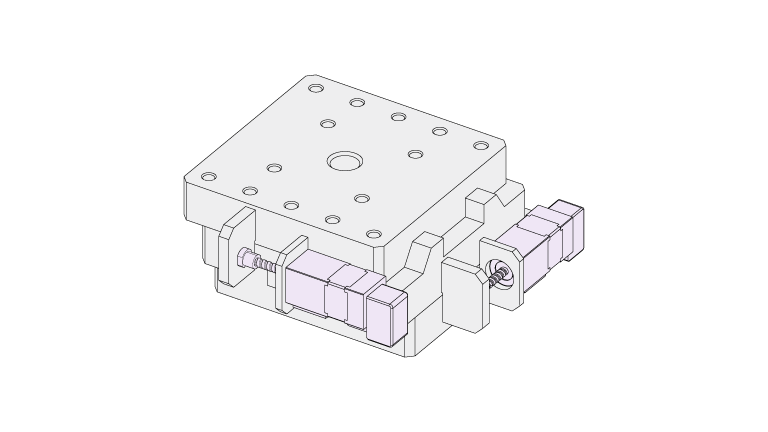

Table Type

This product has high rigidity guide that can fix the load to the cylinder.

Directly installing the load is easy.

Rod Type

The compact shape without any guide allows direct integration into equipment.

This product can be used as a compact thrust shaft in the guide section of equipment for load transportation.

Products With Additional Functions Such as Ball Screw Covers and Mounting Plates are Available

With Ball Screw Cover

The product can be supplied with a ball screw cover for simple dustproofing.

With Mounting Plate

Products with mounting plates are available. 2 product lines are available: one for mounting from the back face using a flange, and the other for mounting from the top using a foot.

Reduces Startup Time

Compact Body Houses Entire Linear Motion Mechanism

As there is no need to make the parts in-house, the time required for "equipment design and parts selection" and "assembly and accurate mounting adjustment" can be reduced, leading to more efficient equipment start-up.

Parameters Required for Operation Already Set

Mechanical parameters such as lead and stroke are set by the ABZO Sensor at the time of shipment. After purchase, it can be set in "mm" units, contributing to reduced equipment start-up time.

No Home Sensor Required

Since position information is managed mechanically by the ABZO sensor, external sensors such as a home sensor and limit sensor are not required. Regular maintenance issues when using external sensors can also be avoided.

Advantages of AZ Series Equipped

Ausgestattet mit batterielosem Absolutencoder

Der Motor ist mit einem kleinen batteriefreien mechanischen Absolutencoder (ABZO-Sensor) ausgestattet. Dies kann dazu beitragen, die Produktivität zu steigern und die Kosten zu senken.

- Mechanischer Encoder

Selbst wenn während des Betriebs die Stromversorgung unterbrochen wird, bleiben die Positionsinformationen erhalten. - Multiturn-Absolutencoder

Die Erkennung der Absolutposition ist im Bereich von ±900 Umdrehungen (1.800 Umdrehungen) der Motorwelle möglich.

Externe Sensoren sind nicht erforderlich

Da es sich um ein Absolutsystem handelt, sind Referenzsensoren oder Endschalter nicht erforderlich.

Vorteile

- Verbesserte schnelle Rückfahrt zum Referenzpunkt und Referenziergenauigkeit

- Reduzierte Kosten

- Einfache Verdrahtung

- Keine Beeinträchtigung durch externe Sensorfehlfunktionen

Batterielos

Mechanische Sensoren benötigen keine Batterien.

Die Positionsinformationen werden mechanisch vom ABZO-Sensor verwaltet.

Vorteile

- Batterien müssen nicht ausgetauscht werden

- Flexible Treiberinstallation

- Sicherheit bei weltweiten Lieferungen

Die Sequenzfunktion vereinfacht die Programmierung

Die Positioniervorgänge der AZ-Serie verfügen über eine Vielzahl von Ablauffunktionen, wie z. B. die Einstellung eines Timers zwischen den Vorgängen und Linked Operation, die bedingte Verzweigung und die Loop-Funktion.

Diese Funktionen können mit der Parametrier-Software MEXE02 eingestellt werden, was das Programm der übergeordneten Steuerung vereinfacht.

- Einstellung der Fahrsatzdaten (max. 256)

- I/O-Signale (6 Eingänge, 6 Ausgänge)

- Remote I/O-Signale (16 Eingangbits, 16 Ausgangsbits)

AZ Series-Equipped Product Line

Since the motors installed are the same, the operating and maintenance methods are the same.

Electric Actuators (AZ Series equipped)

| Electric Linear Slides | Electric Cylinders | Compact Electric Cylinders | Rack-and-Pinion System | Electric Grippers | Hollow Rotary Actuators |

|---|---|---|---|---|---|

| EZS Series | EAC Series | DR Series DRS2 Series |

L Series | EH Series | DGII Series |

- The power supply input of the installed motor differs between Series. Please refer to each series page for the detailed product line.

Driver Features and Product Line

Drivers That Can be Selected to Match the Host Controller

The lineup is available for a variety of controls, systems, and interfaces.

| Driver Type | Compatible Interfaces | Single Axis Driver | |

|---|---|---|---|

| DC Input | |||

|

|||

| Network Compatible | Drivers are controlled directly from a host control device through industrial network | EtherCAT | ○ |

| EtherNet/IP™ | ○ | ||

| PROFINET | ○ | ||

| Built-in Controller | Operation data is built into the driver. Controllable by Modbus (RTU) and I/O. | Modbus (RTU) I/O |

○ |

| Pulse Input with RS-485 Communication | Controlled by pulse signal. Motor status information can be monitored via Modbus (RTU). | Pulse input Modbus (RTU) |

○ |

| Pulse Input | Controlled by pulse signal | Pulse input | ○ |

- DC input mini drivers and multi-axis driver lineups are also available.

Applications and Convenient Usage

Applications

Table Type/Rod Type

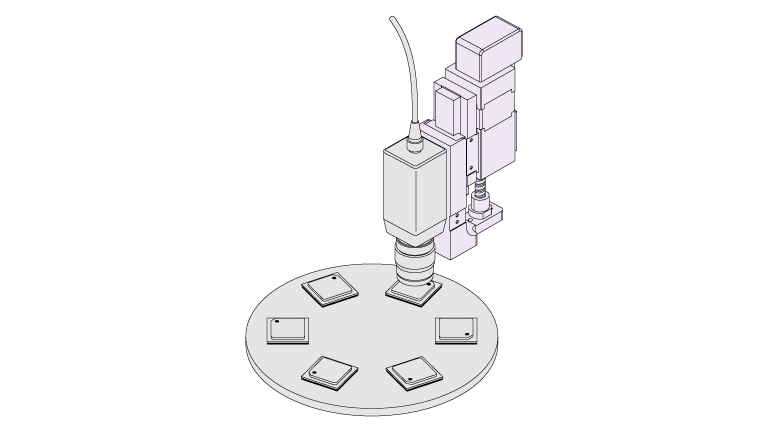

Focusing of a CCD Camera

X-Y Stage Drive

(Automation of micrometer head)

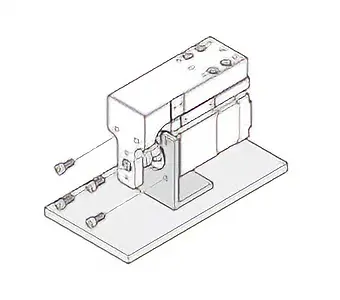

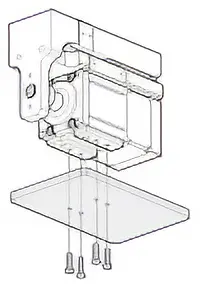

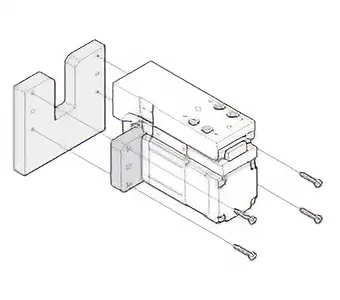

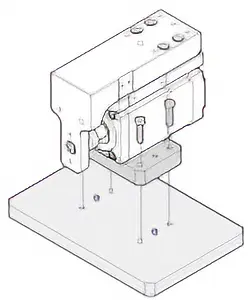

Mounting Example

Table Type/Rod Type

There are 2 types of mounting methods: front mounting and side mounting.

Products with mounting plates (flange* and foot*) can be mounted from the back face using the flange or from the top using the foot.

- *Materials: Aluminum, Surface Treatment: None

| Front Mounting | Side Mounting | Installation With Flange (Except rod type) |

Mounting With Foot (Except DR20 rod type) |

|---|---|---|---|

|

|

|

|

- *The figure shows the table type.

Efficient Push-Motion Operation

Flexible Push Force and Timing

The various types of electric actuator can easily transition to push-motion operation after positioning operations are completed. In addition, push force and timing are flexible.

Note

Please refrain from performing push-motion operation with the DR Series 1 mm lead compact electric cylinders. Because the TLC signal will be output prior to completion of push-motion operation, it may not be completed normally.

Push-motion operation can be used with other electric linear slides, compact electric cylinders, and electric grippers.

Advantages

- You can set the push force and push timing to an operation data number, and then select the data number to change the settings.

- There are different ways to change the pressing phases, such as dropping the force so that the position does not shift, slowly increasing the force, or rapidly increasing the force.

- *The illustrations above are reference diagrams for the DRS2 Series of compact electric cylinders.

Can be Used With Low Speed Push-Motion

The motor can approach the load at high speed. The motor decelerates just before hitting the surface at low speed.

Advantages

- Since the pressing impact is minimal, a mechanism for shock absorption is not required.

- The motor can approach at high speed just before reaching the surface, thus reducing the takt time.

- *The illustrations above are reference diagrams for the DRS2 Series of compact electric cylinders.

Pulse Input Type Can Also be Used for Push-Motion Operation

When T-MODE input is set, push-motion operation is possible, without the overload alarm for the pulse input type being generated.

This is useful for push-motion operation while using pulse input control.

Can Detect Forgotten Load Insertion Without Any External Sensors

The presence or absence of load can be checked by the output signals (TLC output and IN-POS output) from the driver.

-

- IN-POS Output

- Output signal sent when positioning operations are completed.

-

- TLC Output

- Output signal sent when output torque reaches the torque limiting value setting during push-motion operation.

- *The illustrations above are reference diagrams for the DRS2 Series of compact electric cylinders.

Various Operating Patterns and I/O Signals (Applicable to built-in controller type drivers, etc.)

With this type, the operation data is set in the driver, then selected and executed from the host system. In addition, operation data can be combined or shifted to another operation data triggered by an internal or external ON or OFF signal.

Support Software, Monitor Functions

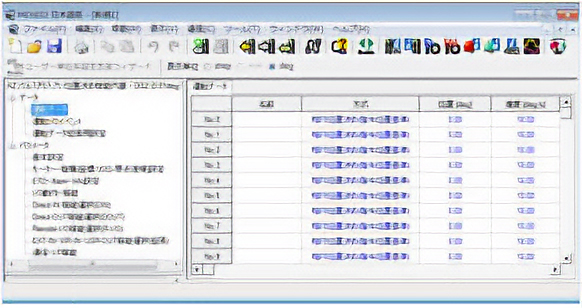

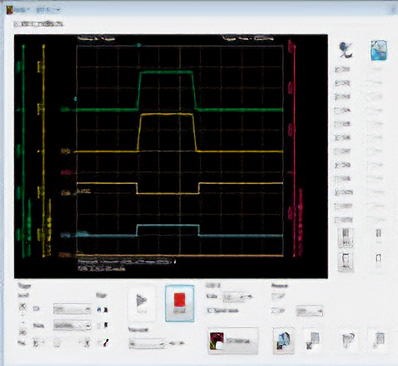

Einfacher Betrieb vom PC mit der Parametrier-Software MEXE02

Mit der Parametrier-Software MEXE02 können Fahrsatzdaten und verschiedene Parameter eingestellt, Positionen geteacht und Antriebe überwacht werden.

Hier klicken, um die Parametrier-Software herunterzuladen

Umfassende Unterstützung durch eine Vielzahl von Funktionen der Software vom Start bis zur Wartung

-

Inbetriebnahme und Test

Nützliche Funktionen für die Verdrahtungsprüfung und eine Testfunktion sind vorhanden.

- Einstellen und Speichern von Fahrsatzdaten

- I/O-Test

- Teaching, Remote Operation

-

Optimierung

Die folgenden Funktionen helfen bei der Optimierung der Fahrsatzdaten nach der Inbetriebnahme des Antriebs.

- Waveform Monitor

-

Diagnose und Wartung

Diagnose- und Wartungsfunktionen stehen für die Fehlerdiagnose und Wartung während des Betriebs zur Verfügung.

- Alarm Monitor

- Unit Information Monitor

- Status Monitor

-

„Operation Data/Parameter Setting“ -

Waveform Monitor

Hier klicken, um Details zu Funktionen der Parametrier-Software zu erhalten

Related Products

Multi-Achs-Treiber der AZ-Serie für DC Stromversorgung

Alle AZ-Motoren für DC Stromversorgung und die mit diesen Motoren ausgestatteten elektrischen Aktuatoren können angeschlossen werden.

-

Für 2 Achsen -

Für 3 Achsen -

Für 4 Achsen

mini-Treiber der AZ-Serie für DC-Stromversorgung

mini-Treiber, kompakter und leichter als ein Standard-Treiber. Unterstützt den Batteriebetrieb und erweitert damit das Spektrum der möglichen Anwendungen.

Produkte eingrenzen