αSTEP AZ Series mini Driver DC Input

AZM14AK+AZD-KREN

| Produktklassifikation | Produktname | Preis | Versand |

|---|---|---|---|

| Motor | AZM14AK | 274.00 € | Up to 5 pcs Estimated Ship 3weeks |

| Control Circuit | AZD-KREN | 476.00 € | Up to 20 pcs Estimated Ship 4weeks |

When connecting to the driver, use a connection cable.

Inklusive

- Motor: None

Control Circuit: None

Spezifikationen

Kennlinien

Speed - Torque Characteristics (Reference values)

Load Torque - Driver Input Current Characteristics

Abmessungen

Motor

Control Circuit

Connection Cable (When Selected)

Daten-Download

Weitere Spezifikationen

Driver Specifications

| Driver Product Name | AZD-KRED | AZD-KREP | AZD-KRPN | AZD-KREN | AZD-KR2D | AZD-KRX | |

|---|---|---|---|---|---|---|---|

| Interface |

Pulse Input | - |

|

||||

| Control Input | 20~32 V DC 2 points, photocoupler |

- | 4.5~32 V DC 5 points, photocoupler |

||||

| Control output | - | 4.5~32 V DC 3 points, photocoupler and open-collector |

|||||

| Field Network |

EtherCAT | EtherNet/IP | PROFINET | Modbus TCP Modbus UDP |

RS-485 Communication | RS-485 Communication | |

Driver function

| Driver Product Name | AZD-KREP AZD-KRPN AZD-KREN AZD-KR2D |

AZD-KRX | |||

|---|---|---|---|---|---|

| Number of Positioning Data Sets | 256 Points | 256 Points*1 | |||

| Remote I/O | Input | 16 Points | |||

| Output | 16 Points | ||||

| Setting Tool | Support Software MEXE02 | ||||

| Coordinates Management Method | Battery-free Absolute System | ||||

| Operation | Positioning Operation | Product Line | Positioning Operation | ○ | |

| Positioning Push-Motion Operation*2 | ○ | ||||

| Fastening method | Single-motion Operation | ○ | |||

| Sequential Operation | ○ | ||||

| Multistep Speed-Change (Configuration Connection) | ○ | ||||

| Sequence Control |

Loop Operation (Repeating) | ○ | |||

| Event Jump Operation | ○ | ||||

| Speed Control Operation (Continuous operation) | ○ | ||||

| Return-To-Home Operation | Return-to-Home Operation*3 | ○ | |||

| High-speed return-to-home operation | ○ | ||||

| JOG Operation | ○ | ||||

| Monitor/Information | Waveform Monitoring | ○ | |||

| Overload Detection | ○ | ||||

| Overheat Detection (Motor and Driver) |

○ | ||||

| Position/Speed Information | ○ | ||||

| Temperature Detection (Motor and Driver) |

○ | ||||

| Motor Load Factor | ○ | ||||

| Travel Distance , Cumulative Travel Distance | ○ | ||||

| Alarm | ○ | ||||

- *1

- It can be used by setting it with the MEXE02 support software.

- *2

- Push-motion operation is not available for the geared motor and electric actuator DGII Series.

- *3

- Return-to-home operation using direct I/O is not available for AZD-KR2D.

Communication Specifications

| Transmission Rate | 100 Mbps |

|---|---|

| Mode | Full duplex (autonegotiation) |

| Cable Specification | Shielded twisted pair (STP) cable Straight/cross, Category 5e or higher recommended |

| Communication Connector | RJ45×2 (shield compatible) |

| Supported Topologies | Star, tree, line |

General Specifications

| Motor | Driver | |||

|---|---|---|---|---|

| AZD-KRED AZD-KREP AZD-KRPN AZD-KREN AZD-KRX |

AZD-KR2D | |||

| Thermal Class | 130(B) [Certified at 105 (A) when UL/CSA Standards were obtained] |

− | ||

| Insulation Resistance |

|

− | ||

| Dielectric Strength |

Sufficient to withstand the following for 1 minute: AZM14, AZM15, AZM24, AZM26

AZM46, AZM48, AZM66, AZM69

|

− | ||

| Operating Environment (when operating) |

Ambient Temperature | 0~+40 ℃ (Non-freezing) | 0~+50 ℃ (Non-freezing) | |

| Ambient Humidity | 85 % max. (Non-condensing) | |||

| Atmosphere | Cable Type: No corrosive gases or dust. No exposure to water, oil or other liquids. Connector type: No corrosive gases or dust. No exposure to oil or other liquids. |

No corrosive gases or dust. No exposure to water, oil or other liquids. | ||

| Degree of Protection |

Cable type (except for mounting surface and connector part): Connector type (when the connection cable is connected. Excluding the mounting surface and connector parts on the driver side of the connection cable): IP66 |

IP20 | IP10 | |

| Stop Position Accuracy |

AZM14, AZM15, AZM24, AZM26: ±5 arcmin (±0.083˚) AZM46, AZM48: ±4 arcmin (±0.067˚) AZM66, AZM69: ±3 arcmin (±0.05˚) |

|||

| Shaft Runout | 0.05 T.I.R. (mm)*3 | − | ||

| Concentricity of Installation Pilot to the Shaft |

0.075 T.I.R. (mm)*3 | − | ||

| Perpendicularity of Mounting Surface to the Shaft |

0.075 T.I.R. (mm)*3 | − | ||

| Multi-Rotation Detection Range in Power OFF State |

AZM14, AZM15, AZM24, AZM26: ±450 rotations (900 rotations) AZM46, AZM48, AZM66, AZM69: ±900 rotations (1800 rotations) |

|||

- *1

- (Only for types with electromagnetic brake)

- *2

- When the motor cable shape is horizontal pull-out

- *3

- T.I.R. (Total Indicator Reading): The total dial gauge reading when the measurement section is rotated once centered on the reference axis center.

Note

- Disconnect the motor and driver when measuring insulation resistance, or conducting a dielectric strength test.

Also, do not conduct these tests on the ABZO sensor part of the motor.

Permissible Radial Load and Permissible Axial Load

| Type | Motor Frame Size Dimension |

Motor Product Name |

Gear Ratio | Permissible Radial Load | Permissible Axial Load |

||||

|---|---|---|---|---|---|---|---|---|---|

| Distance From Shaft End [mm] | |||||||||

| 0 | 5 | 10 | 15 | 20 | |||||

| Standard Type | 20 mm | AZM14 AZM15 AZME14 |

- | 12 | 15 | - | - | - | 3 |

| 28 mm | AZM24 AZM26 AZME24 |

25 | 34 | 52 | - | - | 5 | ||

| 42 mm | AZM46 | 35 | 44 | 58 | 85 | - | 15 | ||

| AZM48 | 30 | 35 | 44 | 58 | 85 | ||||

| 60 mm | AZM66 AZM69 |

90 | 100 | 130 | 180 | 270 | 30 | ||

| 85 mm | AZM98 AZM911 |

260 | 290 | 340 | 390 | 480 | 60 | ||

| TS Geared Type | 42 mm | AZM46 | 3.6, 7.2, 10 | 20 | 30 | 40 | 50 | - | 15 |

| 20, 30 | 40 | 50 | 60 | 70 | - | ||||

| 60 mm | AZM66 | 3.6, 7.2, 10 | 120 | 135 | 150 | 165 | 180 | 40 | |

| 20, 30 | 170 | 185 | 200 | 215 | 230 | ||||

| 90 mm | AZM98 | 3.6, 7.2, 10 | 300 | 325 | 350 | 375 | 400 | 150 | |

| 20, 30 | 400 | 450 | 500 | 550 | 600 | ||||

| PS geared type | 28 mm | AZM24 | 7.2, 10 | 45 | 60 | 80 | 100 | - | 40 |

| 42 mm | AZM46 | 5 | 70 | 80 | 95 | 120 | - | 100 | |

| 7.2 | 80 | 90 | 110 | 140 | - | ||||

| 10 | 85 | 100 | 120 | 150 | - | ||||

| 25 | 120 | 140 | 170 | 210 | - | ||||

| 36 | 130 | 160 | 190 | 240 | - | ||||

| 50 | 150 | 170 | 210 | 260 | - | ||||

| 60 mm | AZM66 | 5 | 170 | 200 | 230 | 270 | 320 | 200 | |

| 7.2 | 200 | 220 | 260 | 310 | 370 | ||||

| 10 | 220 | 250 | 290 | 350 | 410 | ||||

| 25 | 300 | 340 | 400 | 470 | 560 | ||||

| 36 | 340 | 380 | 450 | 530 | 630 | ||||

| 50 | 380 | 430 | 500 | 600 | 700 | ||||

| 90 mm | AZM98 | 5 | 380 | 420 | 470 | 540 | 630 | 600 | |

| 7.2 | 430 | 470 | 530 | 610 | 710 | ||||

| 10 | 480 | 530 | 590 | 680 | 790 | ||||

| 25 | 650 | 720 | 810 | 920 | 1070 | ||||

| 36 | 730 | 810 | 910 | 1040 | 1210 | ||||

| 50 | 820 | 910 | 1020 | 1160 | 1350 | ||||

| PN Geared Type | 28mm | AZM24 | 10 | 45 | 60 | 80 | 100 | - | 40 |

| 42mm | AZM46 | 5 | 80 | 95 | 120 | 160 | - | 100 | |

| 7.2 | 90 | 110 | 130 | 180 | - | ||||

| 10 | 100 | 120 | 150 | 200 | - | ||||

| 60mm | AZM66 | 5 | 240 | 260 | 280 | 300 | 330 | 200 | |

| 7.2 | 270 | 290 | 310 | 340 | 370 | ||||

| 10 | 300 | 320 | 350 | 380 | 410 | ||||

| 90mm | AZM98 | 5 | 370 | 390 | 410 | 430 | 460 | 600 | |

| 7.2 | 410 | 440 | 460 | 490 | 520 | ||||

| 10 | 460 | 490 | 520 | 550 | 580 | ||||

| HPG Geared Type | 40 mm | AZM46 | 5 | 150 | 170 | 190 | 230 | 270 | 430 |

| 9 | 180 | 200 | 230 | 270 | 320 | 510 | |||

| 60 mm | AZM66 | 5 | 250 | 270 | 300 | 330 | 360 | 700 | |

| 15 | 360 | 380 | 420 | 460 | 510 | 980 | |||

| 90 mm | AZM98 | 5 | 600 | 630 | 670 | 710 | 750 | 1460 | |

| 15 | 830 | 880 | 930 | 980 | 1050 | 2030 | |||

| Harmonic Geared Type |

30 mm | AZM24 | 50, 100 | 100 | 135 | 175 | 250 | - | 140 |

| 42 mm | AZM46 | 180 | 220 | 270 | 360 | 510 | 220 | ||

| 60 mm | AZM66 | 320 | 370 | 440 | 550 | 720 | 450 | ||

| 90 mm | AZM98 | 1090 | 1150 | 1230 | 1310 | 1410 | 1300 | ||

| FC Geared Type | 35 mm | AZM24 | 7.2, 15, 25 | 80 | 120 | 180 | 230 | - | 80 |

| 42 mm | AZM46 | 7.2, 10, 20, 30 | 180 | 200 | 220 | 250 | - | 100 | |

| 60 mm | AZM66 | 270 | 290 | 310 | 330 | 350 | 200 | ||

- The product names are listed such that the product names are distinguishable.

- PS,PN, HPG Geared Type: When either the radial load or the axial load is applied, the permissible value is set as a value that satisfies the life of 20,000 hours.

Radial Load and Axial Load

Standards

Regulations and Standards Materials

Documents about compliance with regulations and standards can be downloaded from the "Data Download" tab on the product details page.

(The types of files available for download vary by product.)

Explanations of the Global Laws, Regulations and Standards can be found here.

Information about our compliance with regulations and standards for each of our product series can be found here.

Hazardous Substances

The product does not contain any substances (10 substances) exceeding the regulation values of the RoHS Directive (2011/65/EU, 2015/863/EU).

For more information about compliance with regulations on chemical substances in Oriental Motor's Products, click here.

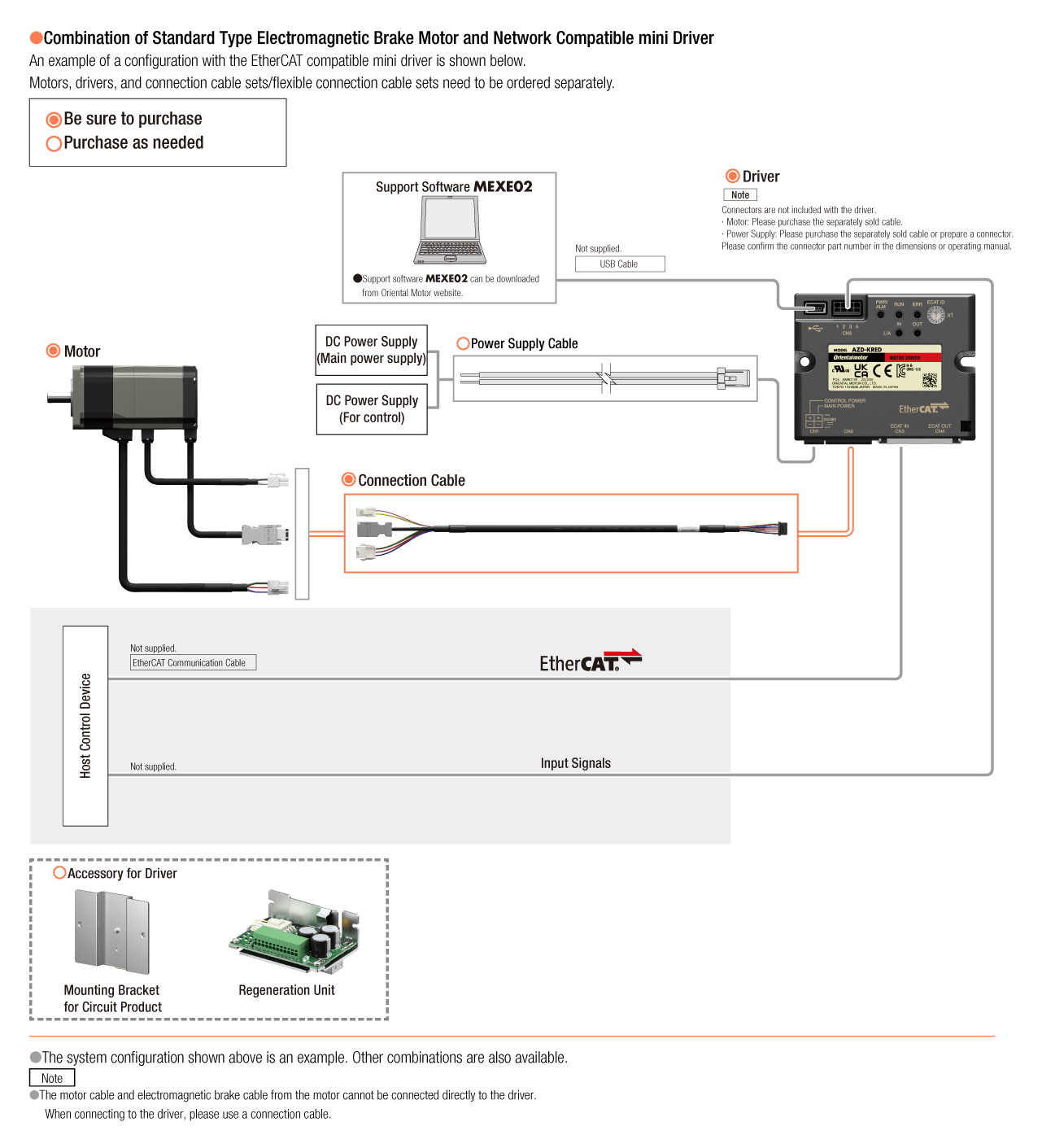

Systemkonfiguration