Select From Electric Actuators - Fine Tuning and Fine Feeding

You can choose from a series of electric actuators with a motor attached to mechanical components. Ready-to-use without the need for installation, adjustment, or inspection.

Compact electric cylinders that integrate a motor with ball screw for linear motion are available.

The effect of backlash due to rigidity and component combinations is minimized to achieve high-precision positioning that contributes to fine tuning and fine feeding.

DRS2/DR Series equipped with battery-free absolute encoder and capable of push-motion operation, and

DRL II Series that achieves low vibration operation and can be combined with CVD driver for 5-phase stepper motor are available.

Battery-Free Built-In Absolute Encoder

DR Series (frame size: 20 mm, 28 mm)Click here for details

DRS2 Series (frame size 42 mm, 60 mm)Click here for details

| Series Name | Frame Size (mm) |

Ball Screw Type |

Accuracy | Stroke (mm) |

||

|---|---|---|---|---|---|---|

| Repetitive positioning accuracy (mm) |

Type | Lost Motion (mm) |

||||

DR Series

|

20 | Precision | ±0.003 | Table type | 0.02 max. | 25 |

| Rod type | ||||||

| 28 | Rolled | ±0.01 | Table type | 0.05 max. | 30 | |

| Precision | ±0.003 [±0.005]* |

0.02 max. | ||||

| Rolled | ±0.01 | Rod type | 0.05 max. | |||

| Precision | ±0.003 | 0.02 max. | ||||

DRS2 Series

|

42 | Rolled | ±0.01 [±0.02]* |

Guide type | 0.05 max. | 40 |

| Precision | ±0.003 [±0.005]* |

0.02 max. | ||||

| Rolled | ±0.01 | Non-guide type | 0.05 max. | |||

| Precision | ±0.003 | 0.02 max. | ||||

| 60 | Rolled | ±0.01 | Non-guide type | 0.05 max. | 50 | |

- Specifications will vary according to conditions. For details, check the specifications for each product.

Can be Combined With CVD Driver

DRL II SeriesClick here for details

| Series Name | Frame Size (mm) |

Ball Screw Type |

Accuracy | Stroke (mm) |

||

|---|---|---|---|---|---|---|

| Repetitive positioning accuracy (mm) |

Type | Lost Motion (mm) |

||||

DRL II Series

|

20 | Precision | ±0.003 [±0.01]* |

Guide type | 0.02 max. | 25 |

| ±0.003 | Non-guide type | |||||

| 28 | Rolled | ±0.01 | Guide type | 0.05 max. | 30 | |

| Non-guide type | ||||||

| Precision | ±0.003 [±0.01]* |

Guide type | 0.02 max. | |||

| ±0.003 | Non-guide type | |||||

| 42 | Precision | ±0.01 | Guide type | 0.05 max. | 40 | |

| Non-guide type | ||||||

| Rolled | ±0.003 [±0.01]* |

Guide type | 0.02 max. | |||

| ±0.003 | Non-guide type | 0.02 max. | ||||

| Precision | ±0.01 | Guide type | 0.05 max. | |||

| Non-guide type | ||||||

| 60 | Rolled | ±0.01 | Guide type | 0.05 max. | 50 | |

| Non-guide type | ||||||

| Precision | ±0.003 [±0.01]* |

Guide type | 0.02 max. | |||

| ±0.003 | Non-guide type | |||||

- Specifications will vary according to conditions. For details, check the specifications for each product.

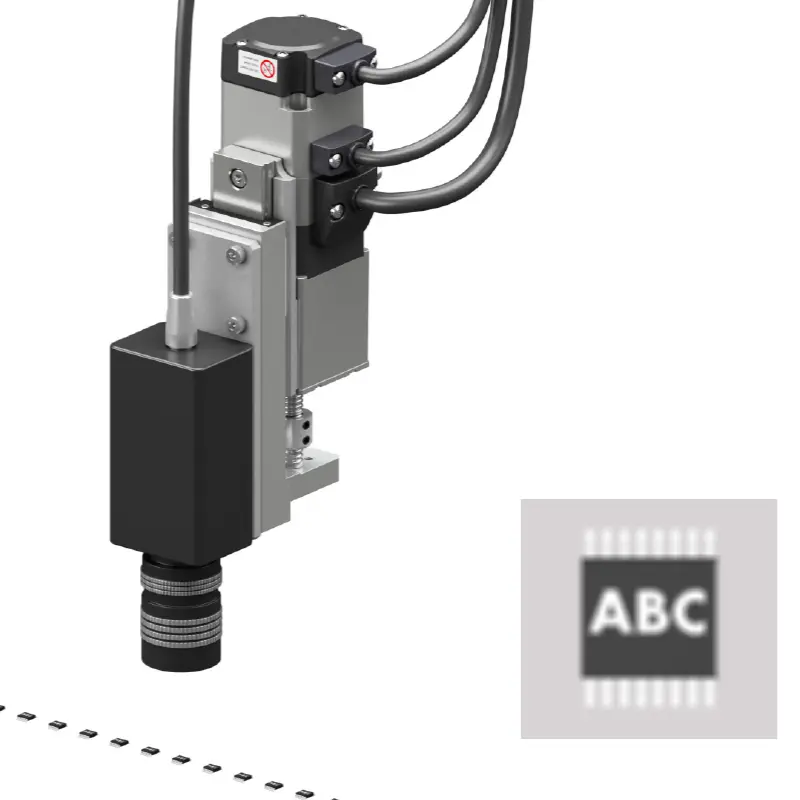

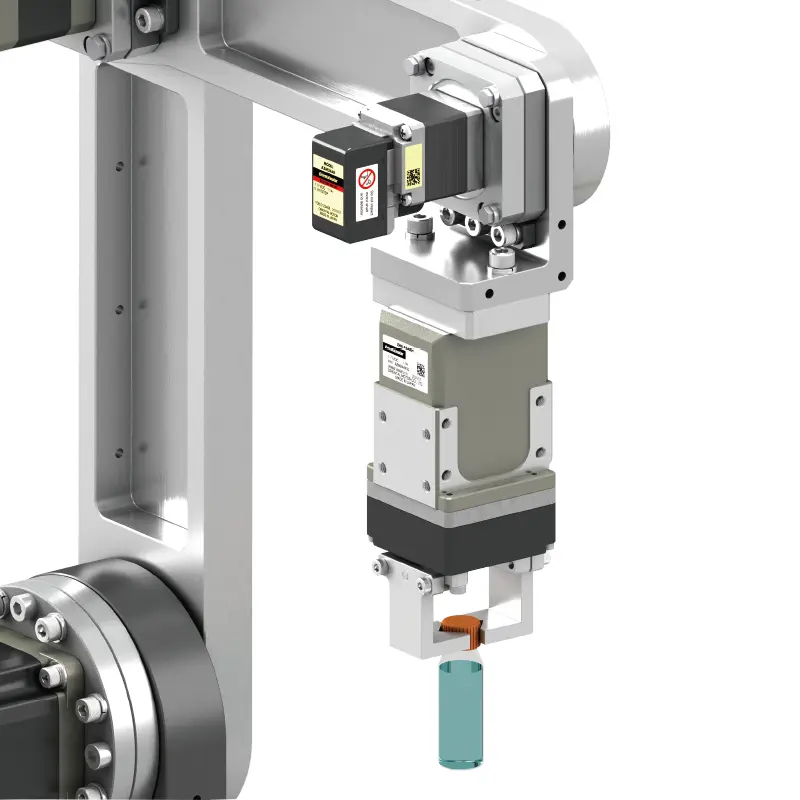

Application Examples

We introduce examples of equipment that we have manufactured in-house and specific solution examples for equipment challenges. Based on these, we provide easy-to-understand illustrations and videos on how to choose and utilize our products.

Click here for details

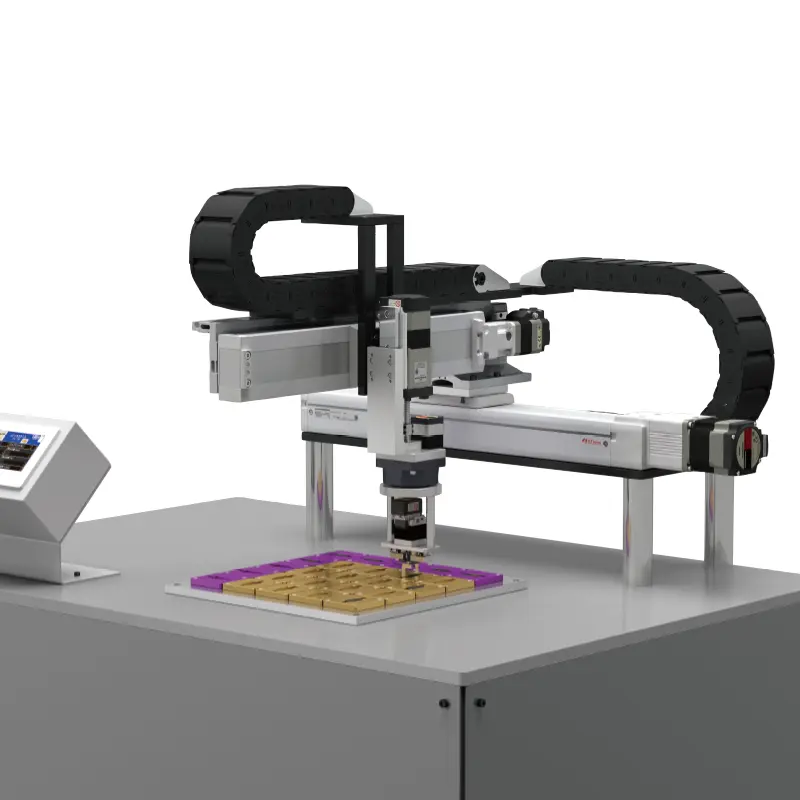

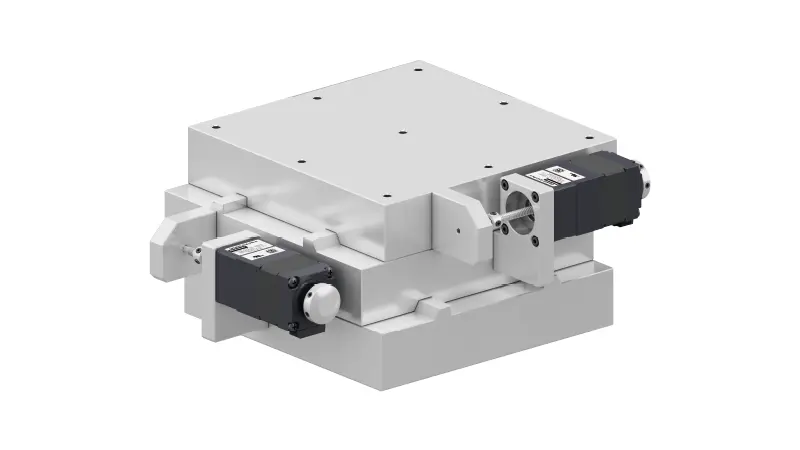

Driving an XY Stage (Automated micrometer head)

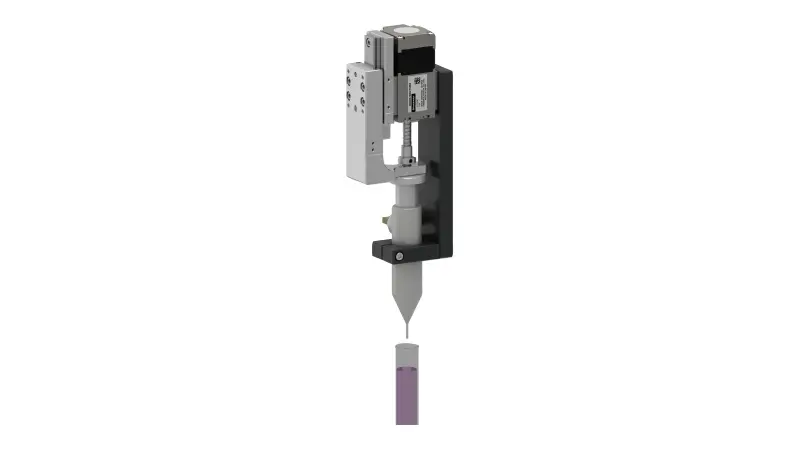

Dispenser (Pouring equipment)

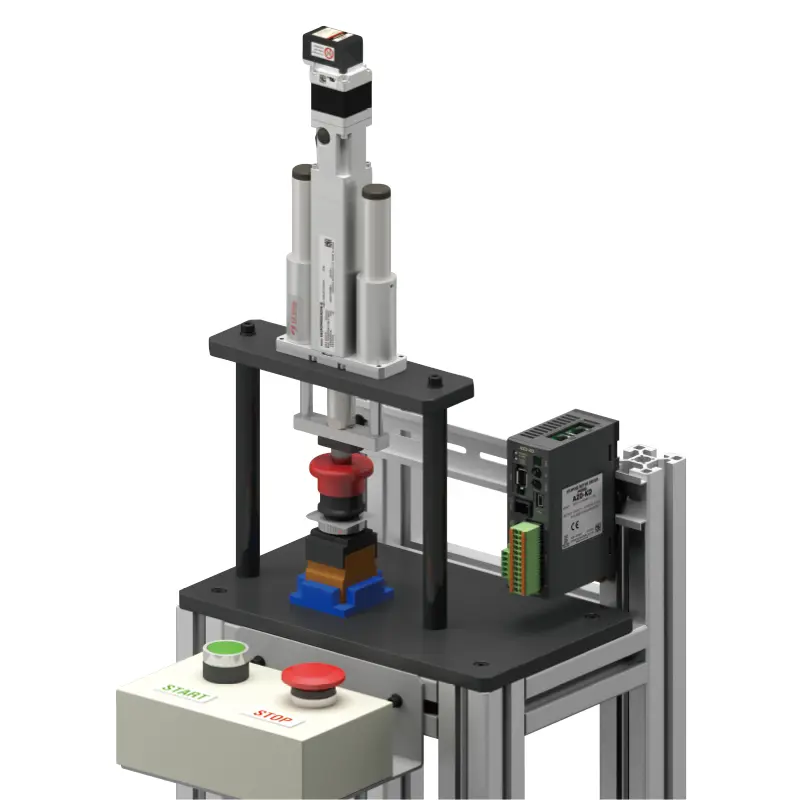

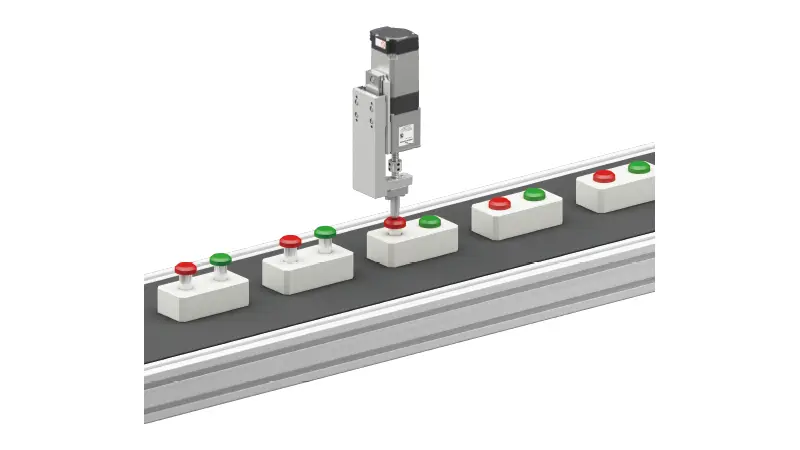

Press Fit Pins