Rack-and-Pinion System

L Series

αSTEP AZ Series Equipped

- A Structure That Integrates a Rack-and-Pinion Mechanism with a Stepper Motor

- Equipped with Closed Loop Stepper Motor

- Stroke 100 to 1000 mm

- Maximum Transportable Mass 100 kg

Features | Rack-and-Pinion System L Series αSTEP AZ Series Equipped

Key Features

Compact Size and Maximum Transportable Mass of 100 kg

Maximum Transportable Mass 100 kg

Larger-diameter pinion with increased gear strength realizes a maximum transportable mass of 100 kg

Maximum Stroke 1000 mm

Product line includes strokes from 100~1000 mm

Comparison With Electric Linear Slide

The rack-and-pinion system can transport the transportable mass if it is mounted without consideration of the moment of inertia.

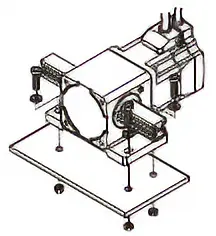

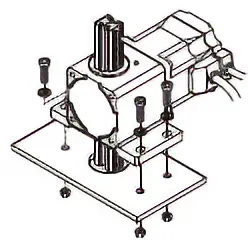

Overview of Rack-and-Pinion System

The rack-and-pinion system can easily convert the rotation of the motor into linear motion.

Although the linear motion mechanism part is compact in design, it can transport a large load due to its high strength processing.

Contributing to Design Efficiency

Reduces Startup Time

The rack-and-pinion system reduces the number of components traditionally used, significantly reducing the man-hours required for design and assembly.

Space Saving

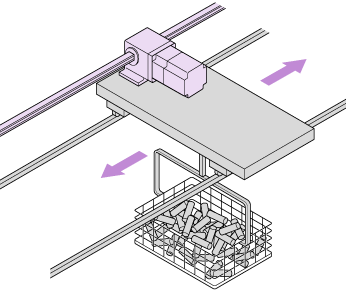

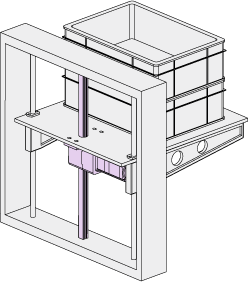

By fixing the screw holes on both ends of the rack, the main unit can be self-propelled. This function is effective for equipment that is too small to provide motor space.

Allows Setting in mm Units

αSTEP AZ Series is used for the drive motor.

Using together with the MEXE02 support software makes setting travel amount in mm units easy, allowing for a variety of linear motion applications.

Minimum Travel Amount

| High-Speed Type | Large Transportable Mass Type |

|---|---|

| 0.01 mm | 0.001 mm |

Operating Speed Range (For AC input type)

| High-Speed Type | Large Transportable Mass Type | |

|---|---|---|

| Frame Size 60 mm | Frame Size 80 mm | |

| 0~500 mm/s | 0~90 mm/s | 0~40 mm/s |

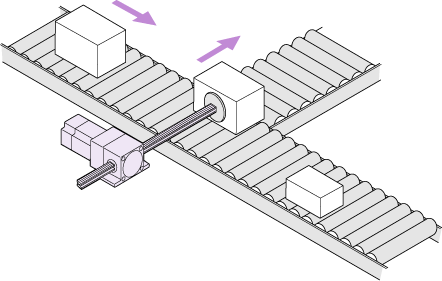

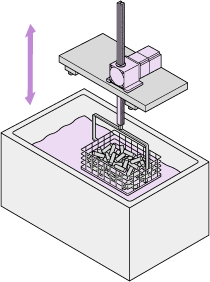

Applications

The rack-and-pinion system, which can be applied to a variety of applications, is a user-friendly product that can be selected as if it were a component.

| Rack Moving Direction | Motor Fixed | Rack Fixed |

|---|---|---|

Parallel (B type) |

Easily move objects by pushing or pulling. |

A wide variety of stroke and speed is available. |

Vertical (F type) |

Vertical operation is also easy. Electromagnetic brake drop protection is also available. |

Using the screw holes at the end of rack simplifies the fastening of loads and rack fixing. |

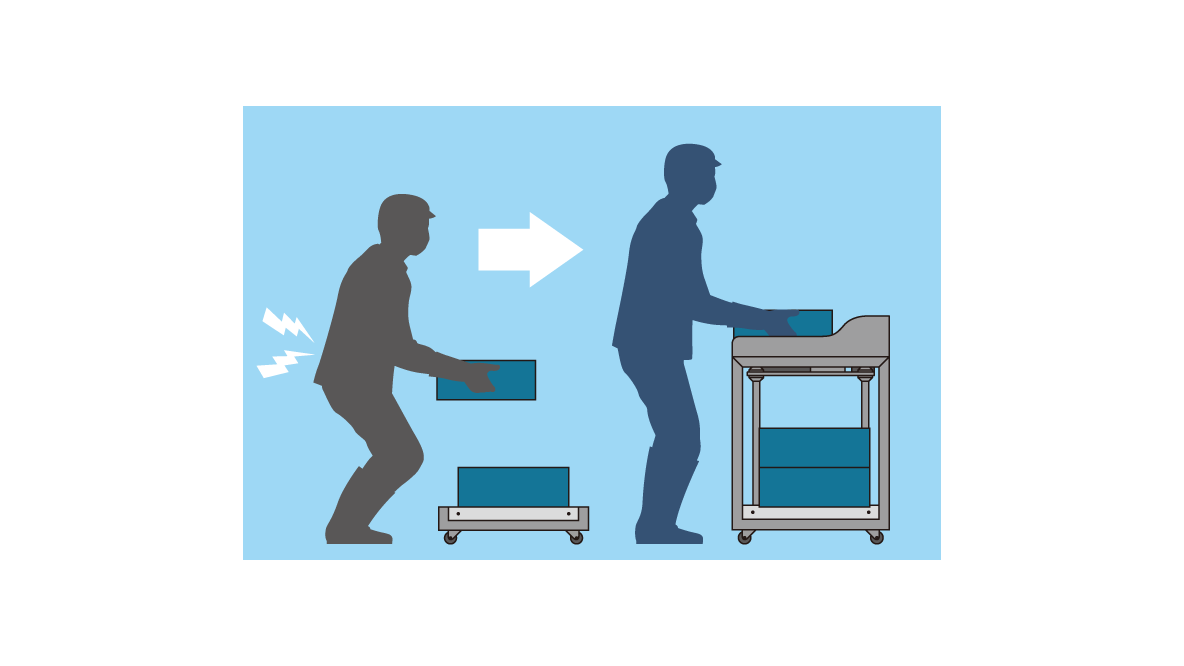

Labor-Saving Ideas

At Japan's Manufacturing sites, labor shortages due to a decline in the working population associated with the decreasing birthrate and aging population is becoming an issue. Amidst this, there is an urgent need for labor-saving that reduces the burden of "heavy lifting work" and "repetitive work such as sorting." Rack-and-pinion system that transports high loads contributing to labor-saving in manufacturing operations.

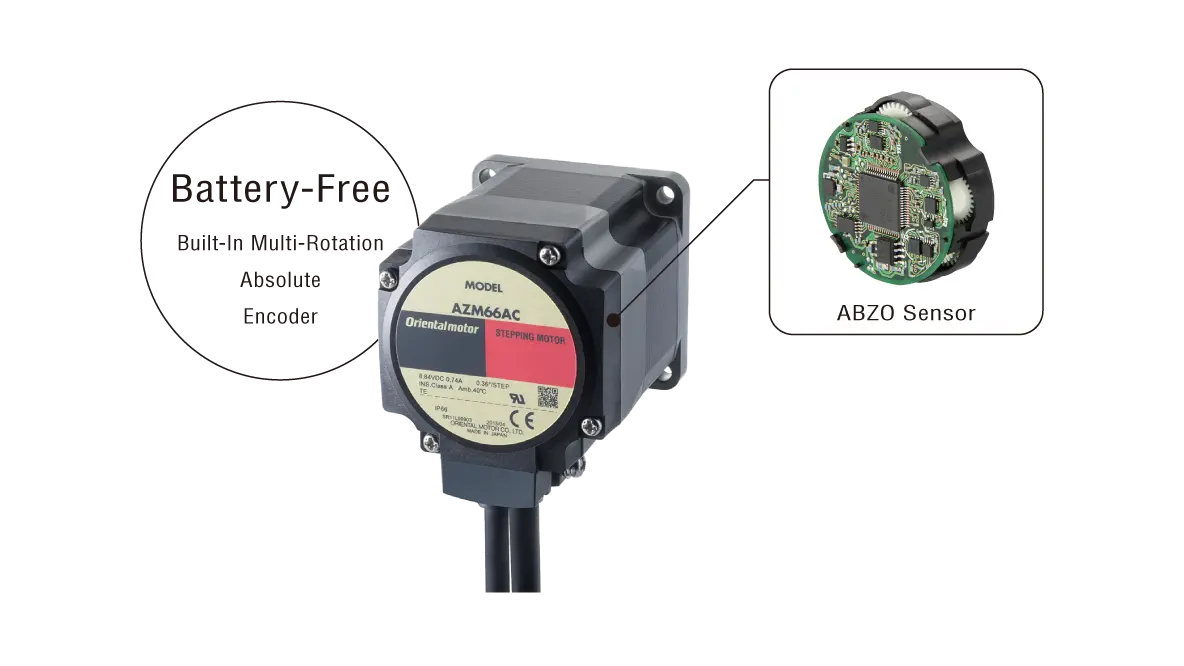

Advantages of AZ Series Equipped

Equipado con Encoder Absoluto Sin Batería

Está equipado con un pequeño encoder absoluto mecánico sin batería (sensor ABZO). Pudiendo contribuir a la mejora de la productividad y reducción de costes.

- Sensor de tipo mecánico

Conserva la información de posicionamiento incluso cuando se corta la alimentación - Encoder absoluto multi-vuelta

La detección de posición absoluta es posible en un rango de ±900 (1800) revoluciones del eje del motor desde la posición de inicio

No se requieren sensores externos

Dado que es un sistema absoluto, no se requieren sensores para el referenciado ni de fin de carrera.

Ventajas

- Mejora en el retorno a origen de alta velocidad y la precisión de dicho posicionamiento (Homing).

- Coste reducido

- Cableado sencillo

- No se ve afectado por el fallo de sensores externo

Sin batería

Los sensores mecánicos no requieren baterías.

El sensor ABZO gestiona mecánicamente la información de posicionamiento.

Ventajas

- No es necesario sustituir las baterías

- Posibilidades ilimitadas de instalación del controlador

- Seguro para envíos al extranjero

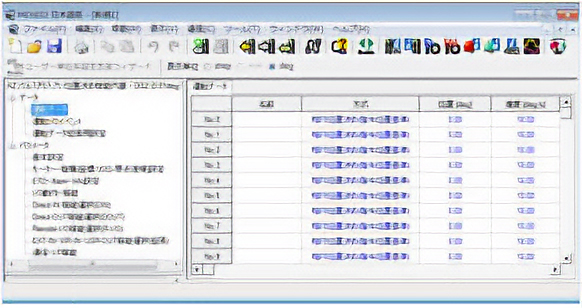

Simplificación del programa principal mediante la función de secuencia

La serie AZ viene equipada con una amplia variedad de funciones para crear secuencias de operaciones, como ajustes de tiempo durante y en el enlazado de movimientos (linked operation), operación condicional y funcionamiento en bucle (loop operation). (excluyendo algunos modelos)

Se puede configurar con el software de soporte MEXE02, simplificando la programación de secuencias del sistema de control principal.

- Configuración de valores de perfiles de posicionamiento (máx. 256)

- Señales de E/S de propósito general (10 entradas, 6 salidas)

- Señales de E/S de comunicación (16 entradas, 16 salidas)

Return-to-Home Not Required (Built-in controller type)

Even if the power shuts down during a positioning operation, the position information is retained. With the built-in controller type, the positioning operation can be restarted without performing return-to-home, after an emergency stop on the production line or a blackout.

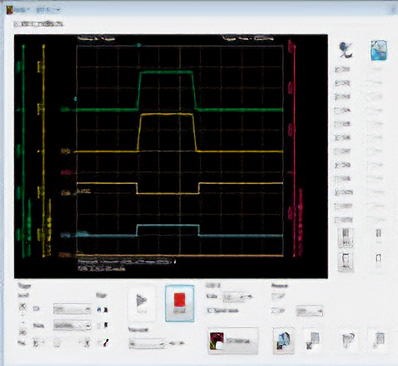

Data Collection of Motor Operation Status and Functions Useful for Preventive and Predictive Maintenance

This software is equipped with various monitoring functions for checking the operating status of the motor.

By using different types of equipment for different situations, it is possible to shorten the start-up and adjustment time of the equipment, as well as to utilize it for maintenance and servicing.

Monitoring Function to Visualize the Motor Operating Status and Help Collect Data

The ABZO sensor bulit in the AZ Series allows you to monitor the motor's operating status numerically.

[Monitoring With MEXE02 Support Software]

In addition, the built-in controller type can realize data collection at a host master via industrial network.

Information Functions Useful for Preventive and Predictive Maintenance

By setting arbitrary numerical values for the monitored information items, external signals can be output when the values are reached.

Importing this information into the host controller helps in early detection of problems and adjustment of product maintenance timing.

Examples of Information Functions

TRIP Information

You can set the number of rotations you want to output in advance, and output when that number is reached. (Motor operation will continue)

Temperature Information

You can set the desired output temperature in advance, and the driver will output when it reaches that temperature. (Motor operation will continue)

Standardized Wiring, Control, and Maintenance Parts

Various actuator products equipped with the αSTEP AZ Series are available.

Each of them has the same motor and driver, for standardized wiring, control, and maintenance parts.

Wiring Standardization

The wiring for motor cables, I/O signals, and power supply is the same.

Control Standardization

These products can be operated via the same method, since the control method is the same. For the network control, the remote I/O and the command code are also the same. It saves you the trouble of creating a program.

Unification of Maintenance Parts

Maintenance parts can be minimized, since the motor, driver, and cable are common to all. Management costs (parts cost, management space) can be reduced.

AZ Series-Equipped Product Line

Electric Actuators (AZ Series Equipped)

| Electric Linear Slides | Electric Cylinders | Compact Electric Cylinders | Rack-and-Pinion System | Electric Grippers | Hollow Rotary Actuators |

|---|---|---|---|---|---|

| EZS Series | EAC Series | DR Series DRS2 Series |

L Series | EH Series | DGII Series |

- The power supply input of the installed motor differs between Series. Please refer to each series page for the detailed product line.

Driver Features and Product Line

Drivers That Can be Selected to Match the Host Controller

| Driver Type | Compatible Interfaces | Single Axis Driver | ||

|---|---|---|---|---|

| AC Input | DC Input | |||

|

|

|||

| Network Compatible | Drivers are controlled directly from a host control device through industrial network | EtherCAT | ○ | ○ |

| EtherNet/IP™ | ○ | ○ | ||

| PROFINET | ○ | ○ | ||

| Built-in Controller | Operation data is built into the driver. Controllable via Modbus (RTU) and I/O. |

Modbus (RTU) I/O |

○ | ○ |

| Pulse Input with RS-485 Communication | Controlled by pulse signal. Motor status information can be monitored via Modbus (RTU). | Pulse input Modbus (RTU) |

○ | ○ |

| Pulse Input | Controlled by pulse signal | Pulse input | ○ | ○ |

- DC input mini drivers and multi-axis driver lineups are also available.

Sencillo control desde PC con el software de soporte MEXE02

Mediante el software de soporte MEXE02, se puede configurar y editar perfiles de movimiento (operation data) y diversos parámetros, además de funciones de teaching y monitorización de estados.

Haga clic aquí para descargar el software de soporte

Soporte integral en puesta en marcha y en mantenimiento gracias a la variedad de funciones

-

Puesta en marcha y evaluación

Se proporcionan funciones útiles disponibles para la comprobación de cableado y prueba de funcionamiento.

- Configuración y almacenamiento de perfiles de movimiento (Operation Data)

- Monitorización de E/S

- Operación remota, teaching

-

Ajuste

Las siguientes funciones están disponibles para ayudarle a ajustar el funcionamiento del motor después de instalar el equipo.

- Monitorización de forma de onda

-

Diagnóstico y mantenimiento

Las funciones de diagnóstico y mantenimiento están disponibles para la resolución de problemas después del inicio de operaciones.

- Monitorización de alarmas

- Monitorización de información de unidades

- Monitorización de estado

-

Pantalla de configuración de parámetros/operation data -

Monitorización de forma de onda

Haga clic aquí para más información sobre las funciones del software de soporte

Product Line

Please purchase the rack and pinion motor, driver and connection cable separately.

L Series AZ Series Equipped

| Rack Moving Direction | Frame Size [mm] |

Type | Power Supply Input | Transportable Mass [kg] |

Operating Speed Range [mm/s] |

Stroke [mm] |

Motor | Electromagnetic Brake |

|---|---|---|---|---|---|---|---|---|

|

|

60 | High speed | AC | 7 | 0 to 500 | 100 to 800 | AZM66 | Not Equipped/Equipped |

| 10 | 0 to 250 | |||||||

| DC | 5 | 0 to 200 | 100 to 500 | |||||

| 10 | 0 to 100 | |||||||

| Large transportable mass | AC | 30 | 0 to 90 | 100 to 800 | ||||

| DC | 0 to 50 | 100 to 500 | ||||||

| 80 | High speed | AC | 7 | 0 to 500 | 100 to 1,000 | |||

| 20 | 0 to 250 | |||||||

| DC | 7 | 0 to 150 | ||||||

| 20 | 0 to 60 | |||||||

| Large transportable mass | AC | 70 | 0 to 40 | |||||

| 100 | 0 to 20 | |||||||

| DC | 50 | 0 to 20 | ||||||

| 100 | 0 to 10 |

Drivers

| Driver Type | Power Supply Input [V] |

|

|---|---|---|

| Built-In Controller | Single-Phase 100-120 Single-Phase/Three-Phase 200-240 DC24/48 |

|

| Pulse Input With RS-485 Communication | ||

| Pulse Input | ||

| EtherCAT Compatible | ||

| EtherNet/IP Compatible | ||

| PROFINET Compatible |

Connection Cable Sets/Flexible Connection Cable Sets

- Motor cable from motor cannot be connected directly to driver. Find the right connection cable.

- Use flexible connection cables for applications where cables are bent.

| Length [m] |

|

|---|---|

|

0.5~20 |

|

Related Products

Controlador multieje Serie AZ con alimentación CC

Permite la conexión de motores Oriental Motor de la serie AZ con especificación de alimentación CC, así como los actuadores eléctricos equipados con dichos motores.

Haga clic aquí para más información

-

Tipo 2 ejes -

Tipo 3 ejes -

Tipo 4 ejes

Mini controlador serie AZ con alimentación CC

Se trata de un mini controlador diseñado para ser más compacto y ligero que un controlador convencional tipo armario. También es compatible con alimentación por batería, por lo que se puede utilizar, más que antes, en un rango todavía mayor de aplicaciones.

Haga clic aquí para más información

Narrow down Products