Proposal for an Electric Actuator That Enables Fine Dispensing in Small Spaces

| Industries | Semiconductors, Displays, Electronic Components |

|---|---|

| Process and Equipment Name | Small Device Assembly Equipment (Fine Dispensing Dispenser Drive) |

| Issue | Space-Saving, Improved Positioning Accuracy, Reduction in Number of Parts |

Issue: To Increase the Accuracy of the Dispensing Process and Downsize the Dispenser Drive Unit.

Conventional Problems

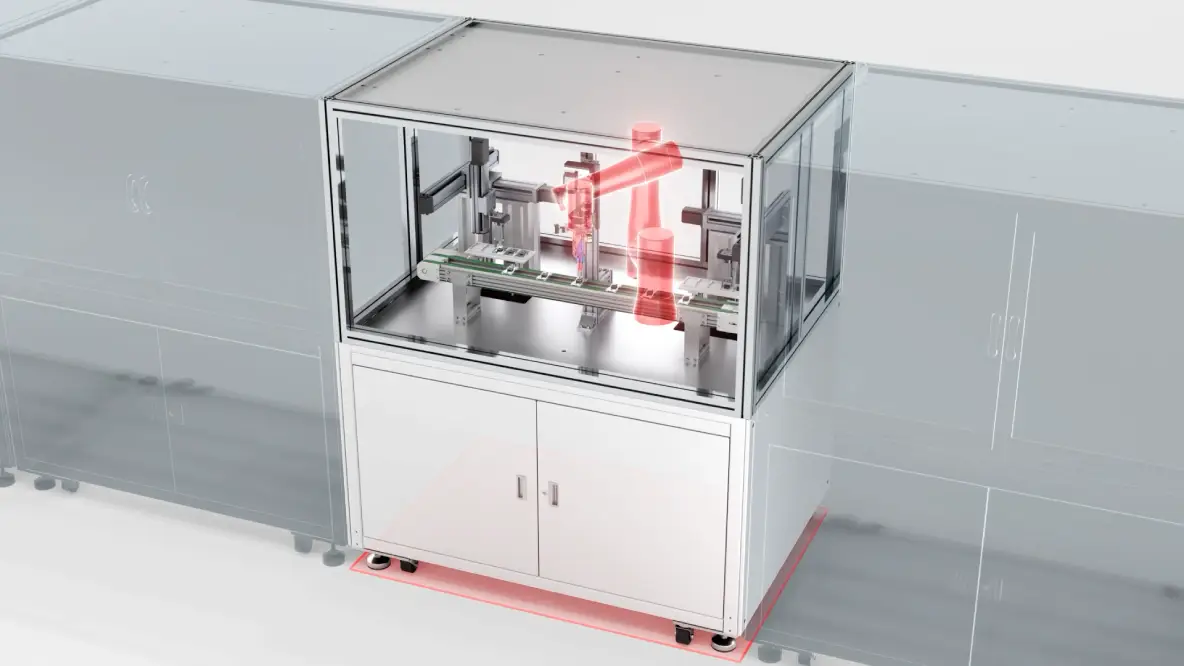

- Since the Dispensing System is Designed for Small Workpieces, a Typical Articulated Robot Would Take Up Too Much Space. It is Necessary to Downsize the Dispenser.

- It is Necessary to Increase the Rigidity of the Dispenser Section to Improve the Accuracy and Stability of the Dispensing Process.

- It is Necessary to Reduce the Man-Hours for Wiring Sensors and Simplify Wiring.

Solution: Highly Rigid Electric Actuator With Built-In Absolute Encoder Enables Downsizing of Precision Dispensing Mechanisms

As devices and workpieces have become smaller, general articulated robots have become too large and difficult to use.

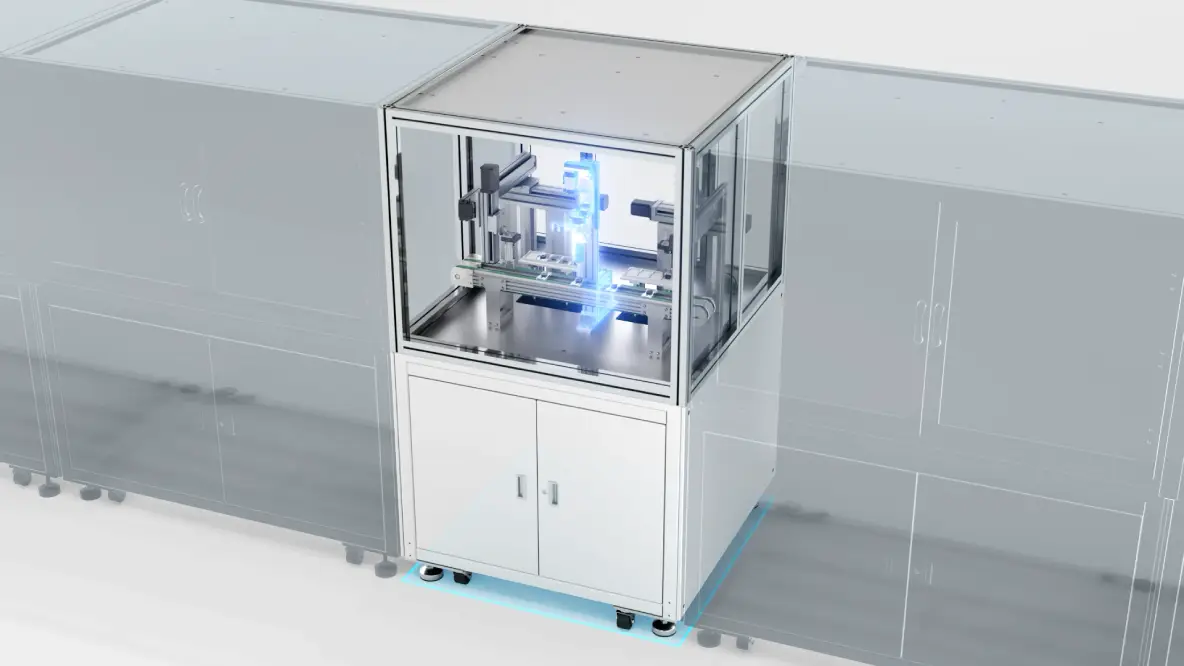

The DGII Series integrates a highly rigid hollow rotary table and a motor with a battery-free built-in absolute encoder, eliminating the need for an external sensor such as a home sensor and saving space. Achieves higher precision and downsizing of the dispenser drive unit. Hollow holes can be used for wiring and piping.

Reduce Design Effort and Downsize Mechanisms

The output table of the hollow rotary actuator DGII series can be directly attached to the table or arm of equipment, and can also be mounted horizontally, on a wall, or on the ceiling. For the dispenser device, a precision X-Y stage is mounted on a ceiling-mounted θ-axis table, allowing the dispenser to be driven in tight spaces. Furthermore, in the Z-axis direction, combining it with a small linear slide downsizes the entire mechanism.

Image of Downsizing Mechanism With Hollow Rotary Actuator DGII Series

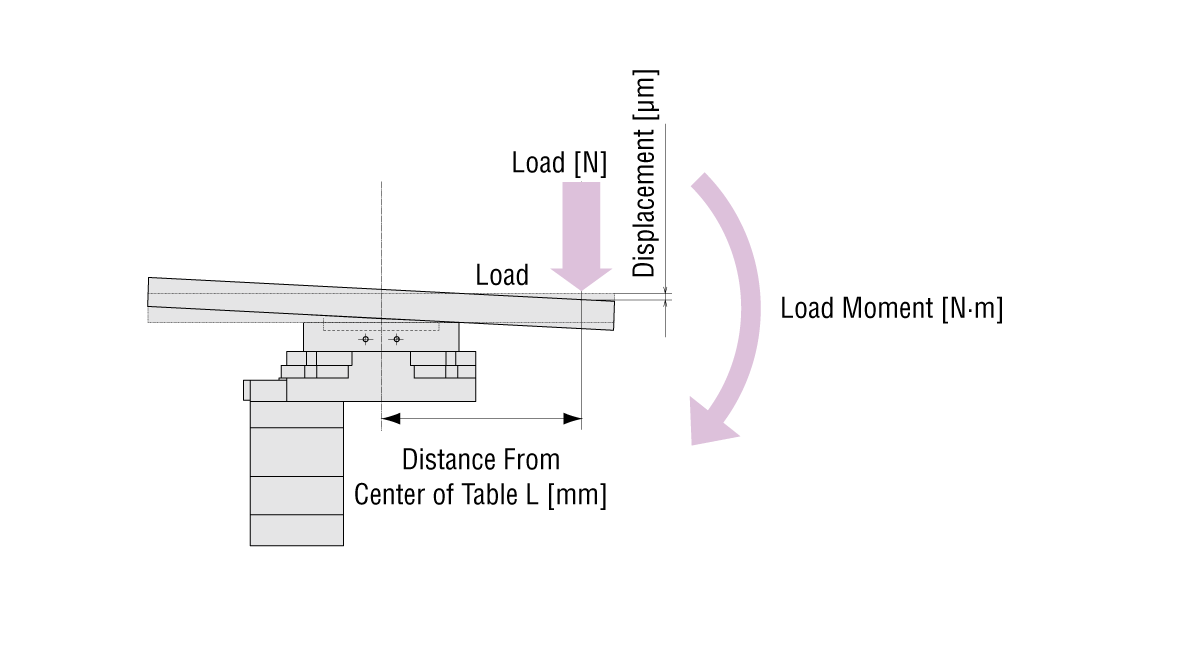

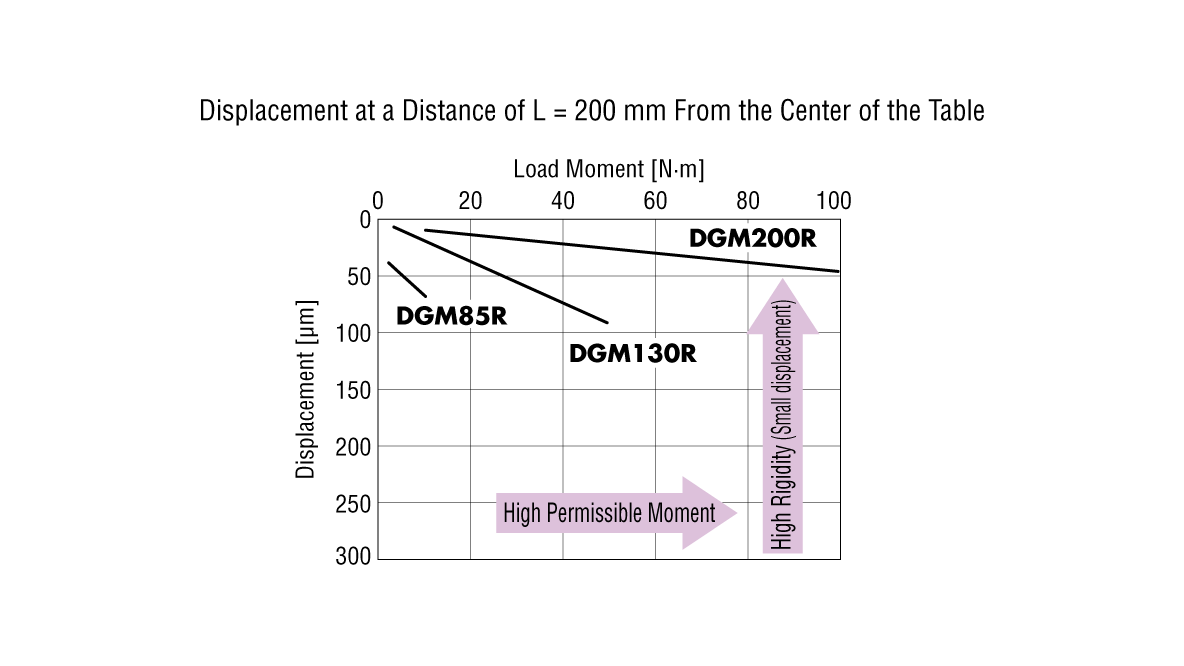

Output Table With Highly Rigid Integrated Structure Enables Precise Dispensing

Hollow rotary actuator DGII Series combines a rotary table mechanism with a motor to achieve high-precision positioning. Non-backlash, repetitive positioning accuracy is ±15 arcsec (±0.004˚). If even greater precision is required, please select a product with a frame size of 85~200 mm, which uses cross roller bearings and has a smaller surface runout.

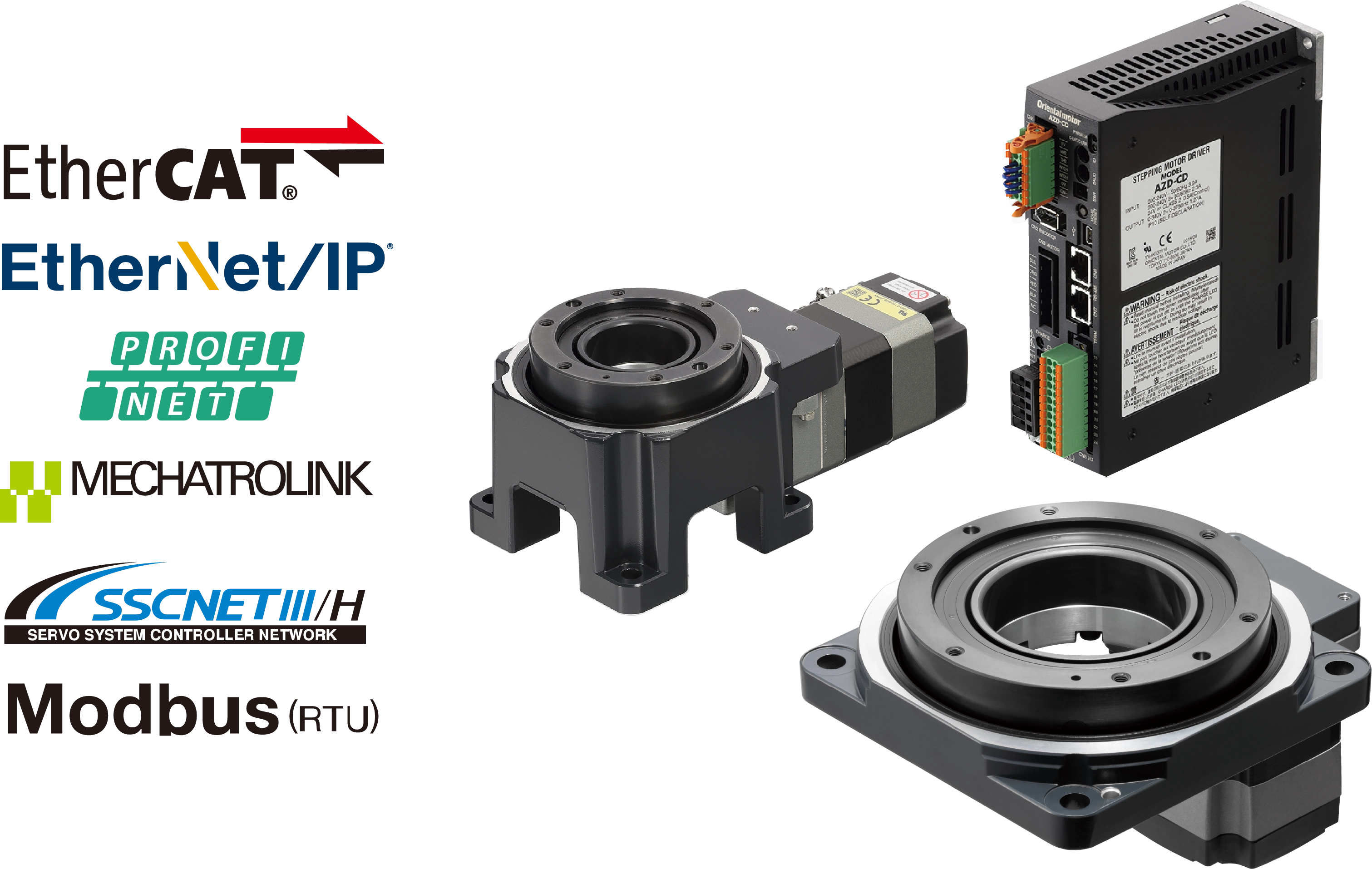

Battery-Free Built-In Absolute Encoder Equipped and Network Compatible for Simple Wiring

The αSTEP AZ Series is used for the motor of the hollow rotary actuator DGII Series. The motor is equipped with a battery-free absolute encoder (ABZO sensor) inside to retain positioning information even when power is not supplied. External sensors such as a home sensor or limit sensor are not required, which saves wiring. If you select a network compatible driver, you can connect the host controller and the driver with just a single communication cable, further reducing wiring.

Product Proposal: Hollow Rotary Actuator DGII Series

Actuator

Frame size □60 mm □85 mm □130 mm □200 mm

Combinable Drivers

AZ Series Drivers (Network Compatible, Built-in Controller, Pulse Input with RS-485 Communication, Pulse Input, Network Compatible Multi-axis, Mini)

●Servo motor AZX Series equipped with DGM200R (□200 mm) is also available.