Stepper Motor Fully Closed-Loop Control System for Improved Alignment Accuracy at Reasonable Cost

| Industries | Semiconductors, Displays, Electronic Components |

|---|---|

| Process and Equipment Name | Precision Optical Inspection Equipment |

| Issue | Positioning Accuracy Improvement, Cost Reduction, Vibration Control |

Issue: To Increase the Accuracy of Alignment Units and Reduce Equipment Costs

Conventional Problems

- Alignment Accuracy is Unstable Due to Assembly Errors in the Mechanism.

- I Would Like to Reduce Minute Vibrations in the Mechanism.

- I Have Fully Closed-Loop Control With Servo Motors, but I Would Like to Reduce the Equipment Cost Compared to the Current System.

Solution: Fully Closed-Loop Control of Geared 5-Phase Stepper Motors for Cost Reduction and High-Precision Positioning

In precision optical equipment, assembly errors and minute vibrations of the positioning stage can affect alignment accuracy.

By combining CVD Series fully closed-loop control type driver with a harmonic geared type 5-phase stepper motor, you can achieve high-precision positioning while maintaining the usability of a stepper motor.

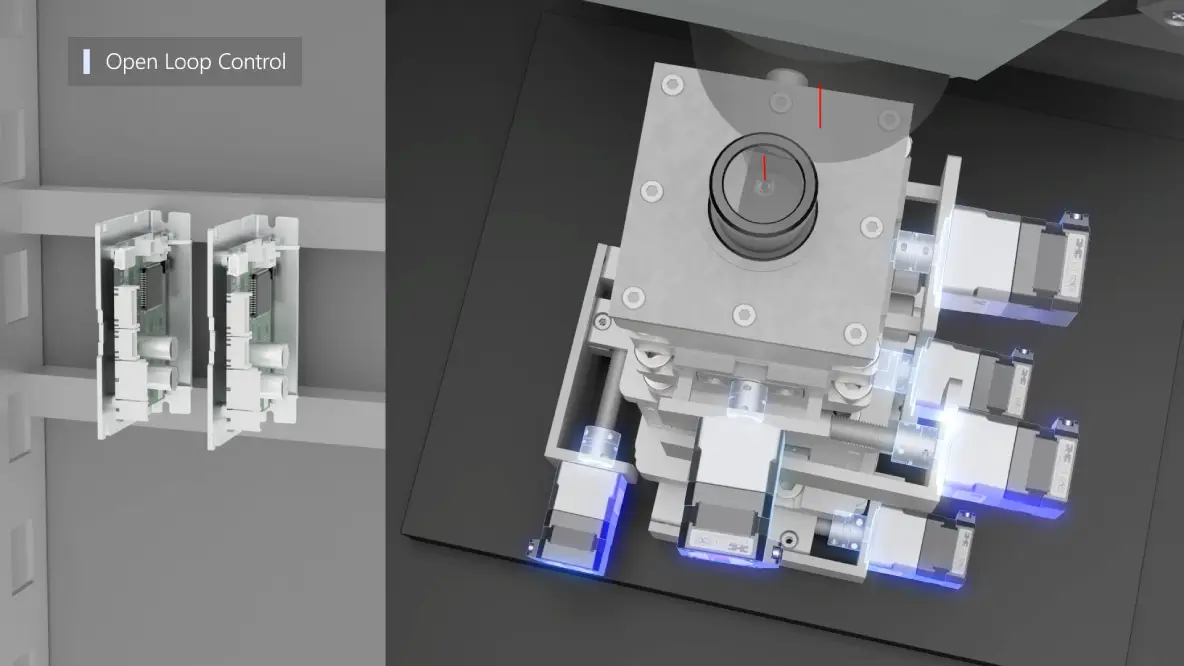

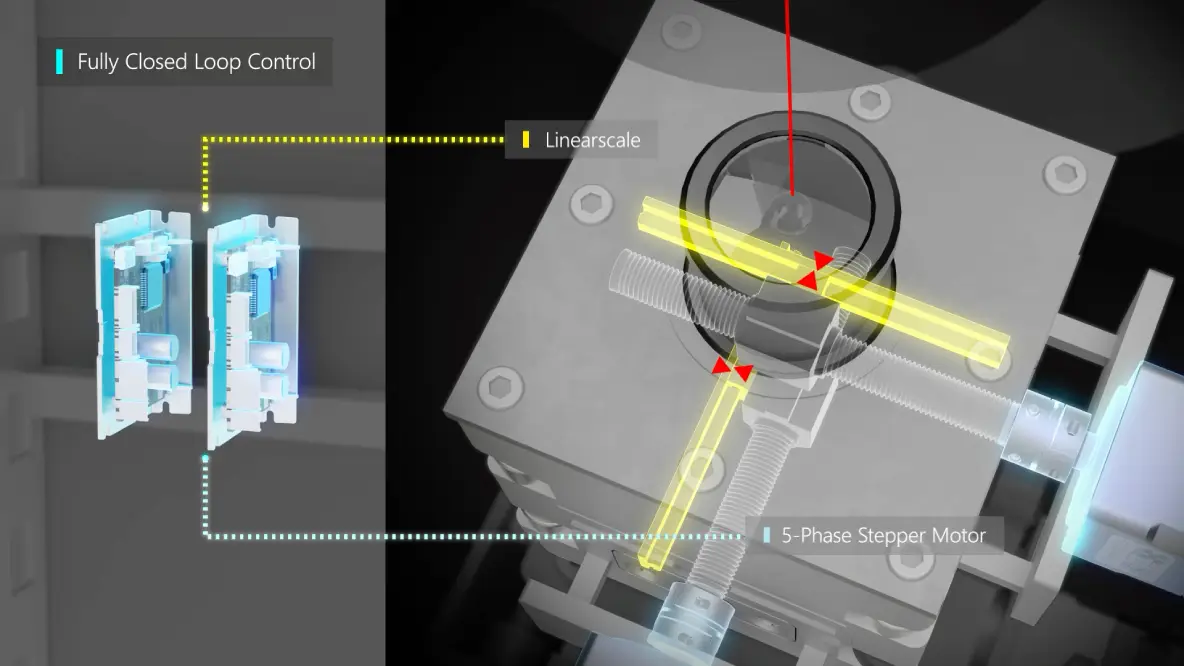

Fully Closed-Loop Control for Final Position Adjustment Only to Prevent Over-Specification

Stepper Motors are suitable for high accuracy positioning over a short distance. When the positioning distance is short, as in the case of the final positioning axis, a 5-phase stepper motor and CVD Series fully closed-loop control type driver can be used to reduce system configuration costs. In this system, feedback of positioning performed by open-loop control is sent from the linear encoder to the driver, which transitions to position compensation via fully closed-loop control when the position command is complete. Final adjustment with fully closed-loop control allows for highly accurate positioning within submicron.

Image of Final Positioning With CVD Series Fully Closed-Loop Control Type Driver

High Positioning Accuracy in Combination With the Harmonic Gearhead Type

High positioning accuracy can be achieved by using a non-backlash harmonic geared 5-phase stepper motor. The harmonic gearhead type with high gear ratio is resistant to load fluctuations and reduces motor shaft vibration, contributing to stable positioning.

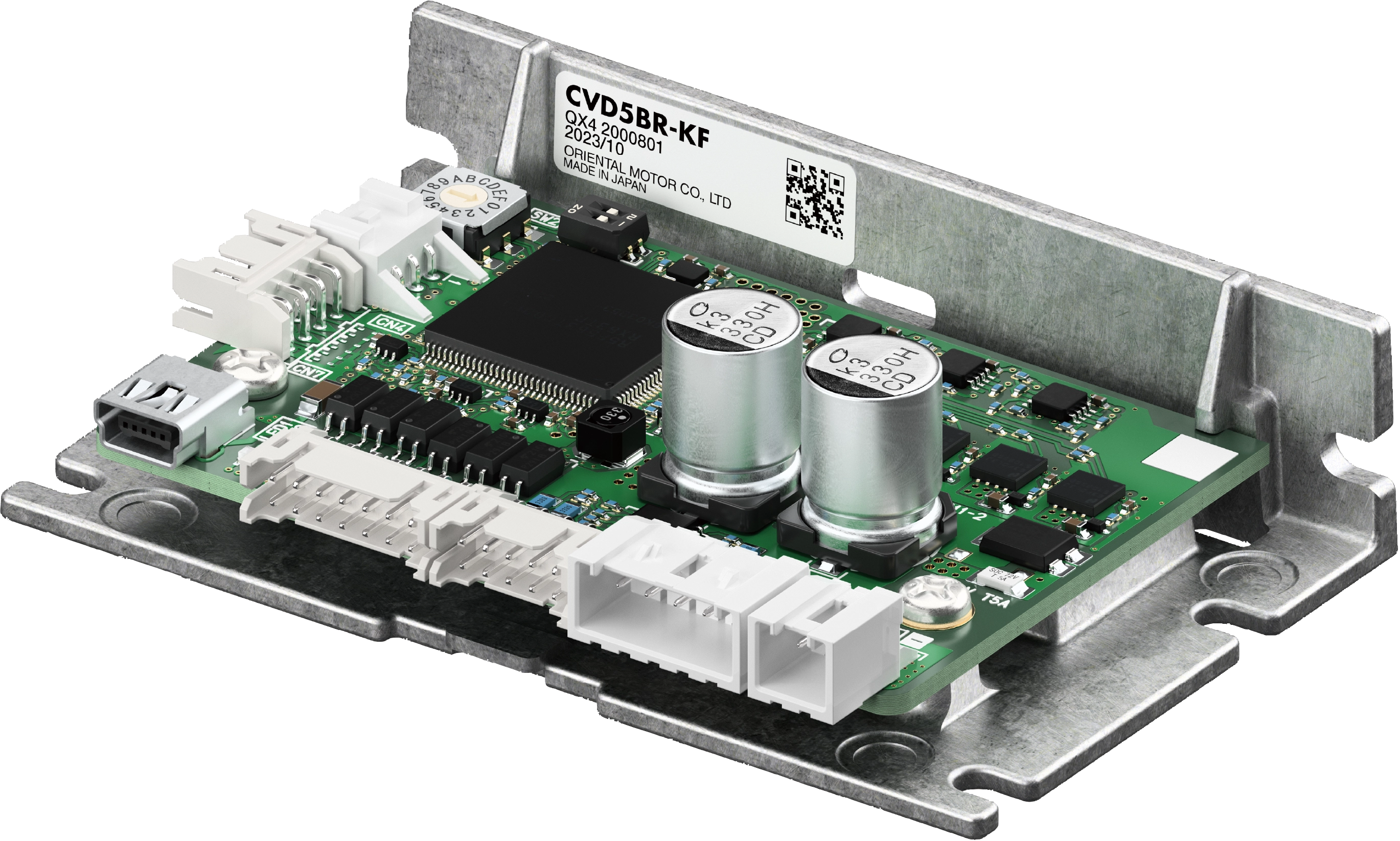

Fully Closed-Loop Control of Stepper Motors Reduces Configuration Costs

The CVD Series fully closed-loop control type makes it possible to configure a fully closed-loop control system at a reasonable cost. Combined with the compact, high-torque 5-phase stepper motor PKP/PK Series also contributes to space-saving.

Applicable Product: CVD Series Fully Closed-loop Control Type

Combinable Motors

- 5-Phase Stepper Motor PKP Series

- 5-Phase Stepper Motor PK Series