Parts Feeder Case Study of Improvement of Supply Stability

Issue

Stable supply without being affected by factory voltage fluctuations

or workpiece types

Conventional Equipment

Equipment uses a three-phase induction motor to vibrate a feeder and orient a load in a certain direction before sending it to the next production process. (An inverter is used for speed control)

- Application

- Organizing and supplying springs, clips, etc.

Conventional Problems

- The supply speed will change due to voltage fluctuations caused by the time of day and equipment usage conditions.

- For large or heavy loads, the supply speed experiences a time lag as load increases

- Speed should change depending on load type, but fine adjustment is difficult

Solution

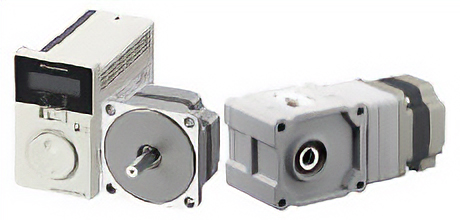

Brushless Motor BMU Series

Excellent Speed Stability and Speed Setting in 1 r/min Increments

for Stable Feeding

The Brushless Motor BMU Series provides a stable supply that is not affected by changes in workpiece shape and weight, or by voltage fluctuations in the factory. Speed can also be set in increments of 1 r/min, allowing for detailed speed settings to match load type.

Specific Application Examples

Excellent Speed Stability for Both Load and Voltage

Feedback control and PWM control allow for operation at a steady speed even with fluctuations to load or voltage.

| BMU Series | General Three-Phase Induction Motor (Combined with General-Purpose Inverter) |

|

|---|---|---|

| Speed Regulation | ±0.2 % max. (Load, Voltage) |

-10 % (V/f control reference value) |

For example, compare motor shaft speed fluctuations when the BMU Series is driven at 3000 r/min and a general purpose inverter controlled three-phase induction motor is driven at 1500 r/min.

The three-phase induction motor side experiences speed fluctuations of about 150 r/min. Speed fluctuation in the BMU Series, on the other hand, is only 12 r/min (±6 r/min).

Digital Detailed Speed Setting

Speed can be fine-tuned using digital settings in increments of 1 r/min.

The speed can be changed easily by setting the potentiometer on the front panel.

A Fanless Design Prevents Dust Agitation

Because brushless motors do not have cooling fans, they do not stir up dust. This prevents foreign particles from contaminating and adhering to loads.

An Extensive Product Line for Easy Selection and Affordability

| Rated Output Power | 30 W, 60 W, 120 W, 200 W, 400 W |

|---|---|

| Output Shaft Type | Round Shaft Type, Parallel Shaft Gearhead (2 Types) Right-Angle Shaft Hollow Hypoid Gear, Foot Mount Gearhead |

| Speed Control Range | 80~4000 r/min*1 |

- *1

- Varies with some gearheads.