Watertight and Dust-Resistant Standard Motor (IP67) Water-Washing Resistant Test

"Water-Washing Resistant Test" With Consideration to Deterioration Over Time - Original Evaluation of Oriental Motor -

The degree of protection indicated by IP is an evaluation of the watertight and dust-resistant performance of the motor in a new condition.

In reality, the sealing insert parts (O-rings) may deteriorate during use of the motor, and the initial waterproofness may not be maintained.

Therefore, we have our own evaluation standard, the "Water-Washing Resistant Test," which takes into account the deterioration of sealing insert parts over time, and confirm that there is no water penetration into the motor.

Oriental Motor's Original "Water-Washing Resistant Test"*

- ① Thermal Shock Test

- Apply heat deterioration equivalent to 5 years for sealing insert (O-ring)

- ② Vibration Test

- Apply vibration to the motor

- ③ Water Jet Test

- Apply water pressure of 100 kPa.

- *This is a test based on Oriental Motor’s own conditions and methods, and does not guarantee trouble-free operation.

Applicable Products

-

Easy operation just to rotate and push the setting dial, and simple wiring only to connect the motor and driver. This brushless motor is frequency independent, and has excellent speed stability.

-

Speed settings up to 16 speeds and torque limiting are available. A compact, high power, and high efficiency brushless motor with excellent speed stability, regardless of frequency.

Test Conditions

① Thermal Shock Test (Rapid temperature change test)

Subjecting a sealing insert part (O-ring) to heat deterioration equivalent to 5 years. (IEC 60068-2-14)

- Setting Temperature

- Low temperature: -24 °C, High temperature: 100 °C

- Time Maintained at These Conditions

- Low temperature: 85 minutes, High temperature: 75 minutes

- Number of Cycles

- 110 cycles

② Vibration Test

Apply vibration under the following conditions. (IEC 60068-2-6, Appendix C)

| Vibration frequency range | : | 10~150 Hz and 10~60 Hz | : | double amplitudes 0.7 mm |

| and 60~150 Hz | : | acceleration 50 m/s2 | ||

| Vibration direction | : | 3 directions (X, Y, Z) | ||

| Number of sweep cycles | : | 20 cycles in each direction | ||

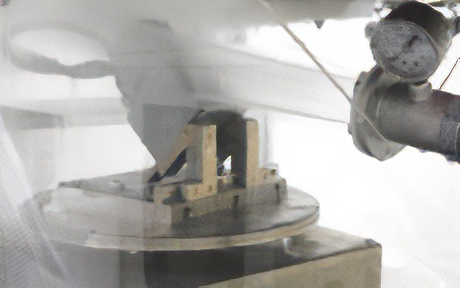

③ Water Jet Test

Perform a water jet test with a water pressure of 100 kPa and a flow rate of 100 L/min at the point where the sealing insert parts exist.

- Criteria

- No water intrusion into the motor.

Details of the Test

First, accelerated deterioration equivalent to 5 years is conducted using the thermal shock test described in ① above.

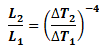

The concept of accelerated deterioration by the rapid temperature change test is as follows.

- L2

- Number of test cycles

- L1

- Expected number of cycles

- ΔT1

- temperature difference of operating conditions [°C]

(Motor surface temperature rise + motor surrounding environmental temperature change)

- ΔT2

- Temperature difference between test conditions [°C]

Here, the expected number of cycles is the number of temperature changes, and a temperature change in 1 day is counted as 1 cycle.

The number of cycles for 5 years, which is the assumption for this test, is 1825.

In addition, the temperature conditions for the test conditions are within the operating temperature range of the O-ring.

Based on these conditions, the number of test cycles was calculated.

In addition, the vibration in ② above is given in consideration of the fact that the sealing insert parts may shift due to vibration.

Watertight, dust-resistant motors (IP67) are assumed to be washed with water at a pressure of 100 kPa, and this is reflected in the water jet test in ③ above.