Gearhead/Linear Head: Gearheads for AC Motors

Since AC motor gearheads are used continuously, primarily for transmitting power, they are designed with priority on ensuring high permissible torque, long life, noise reduction and an extensive gear ratio product line.

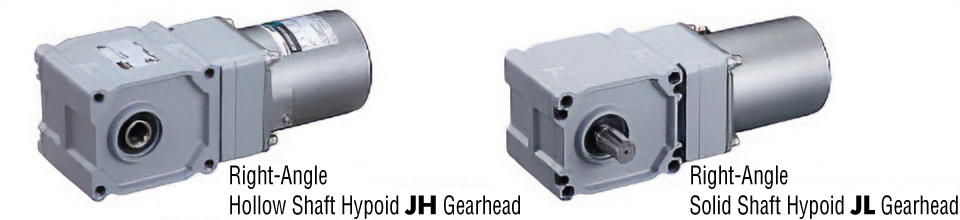

Right-Angle Gearheads

The right-angle gearhead is designed to facilitate the efficient use of limited installation space and the elimination of couplings and other power-transmission components (in the case of the hollow shaft gearhead). Oriental Motor offers right-angle gearheads, including right-angle hollow shaft gearheads as well as right-angle solid shaft gearheads that use hypoid gears, and right-angle hollow shaft gearheads as well right-angle solid shaft gearheads that use worm gears or crossed helical gears.

We also offer right-angle gearheads for high precision positioning, consisting of face gears (disk-shaped gears) and spur gears.

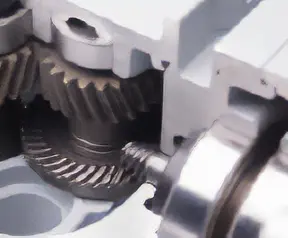

Hypoid Gears

-

The hypoid gear is a conical gear with curved tooth trace for transmitting power between skew gear shafts

-

The hypoid is placed in the first stage and the gear in the last stage is larger, resulting in high strength.

Worm Gears

The worm gear has a history as long as the spur gear, but its applications have been limited compared to the spur gear due to its relatively low efficiency and difficulty in fabrication. Oriental Motor has successfully incorporated the worm gear based on its right-angle property and capacity for large gear ratios, and has improved its efficiency over conventional types by increasing the lead.

Crossed Helical Gears

The crossed helical gear is a standard helical gear on its own. While mating parallel shaft helical gears have equal torsion angle and contact with the helixes running in opposite directions, the crossed helical gears are designed to contact with their shafts crossing perpendicularly. Crossed helical gears are often used with relatively light loads due to its point contact characteristics. In Oriental Motor's right-angle gearheads, they are mainly used at low gear ratios.

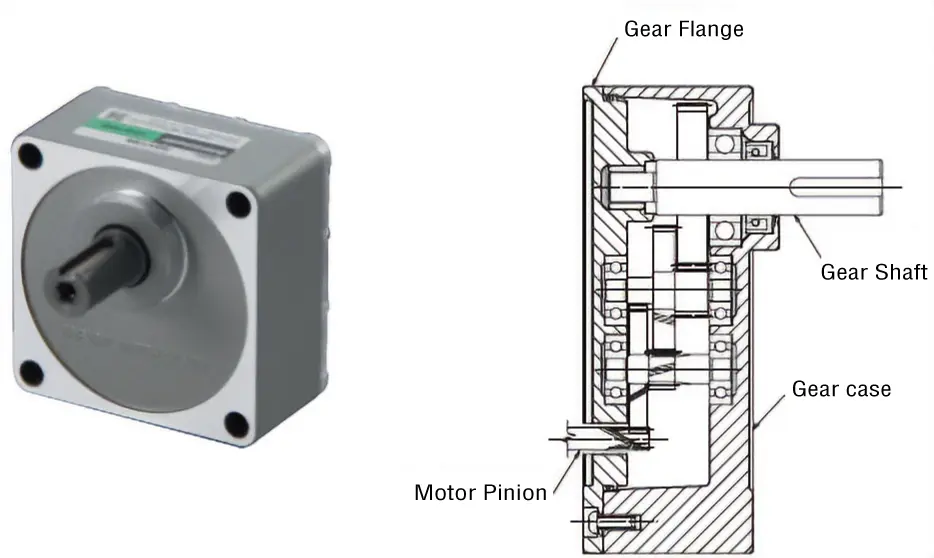

Parallel Shaft Gearhead

Oriental Motor's parallel shaft gearheads use spur gears and helical gears. In particular, helical gears are used to reduce noise and improve strength.

GV Gearhead, GFV Gearhead

The GV gearhead and GFV gearhead are designed for noise reduction through improving gear case rigidity, further improvement of gear machining technology, and higher accuracy in assembly technology.

By using high-strength carburized gears and larger diameter bearings, the GV and GFV gearheads achieve 2 to 3 times more permissible torque than the conventional GN-K gearheads, and have a rated life of 10,000 hours.

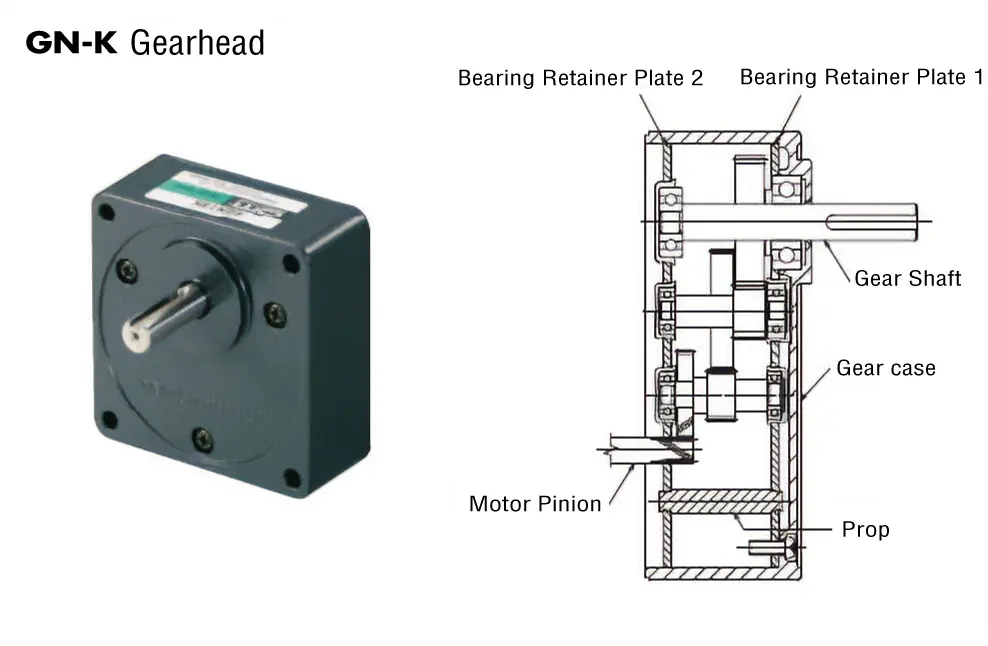

GN-K Gearhead

In order to reduce the noise level, GN-K gearheads employ a helical gear for the motor pinion, which has a fast peripheral speed of meshing and affects the noise level the most, as well as for its corresponding gear.