Fully Closed-loop Control of Stepper Motors for Meeting Miniaturization Requirements

| Industries | Semiconductors, Displays, Electronic Components |

|---|---|

| Process/Device Name | Semiconductor Manufacturing Equipment (Inspection, Ion Implantation, Exposure, etc.) |

| Issue | Improvement of Positioning Accuracy, Cost Reduction, Hunting |

Issue: To Improve Alignment Accuracy

Conventional Problems

- It is Necessary to Meet the Demand for Miniaturization in the Semiconductor Manufacturing Process, But The Current Positioning Accuracy is Insufficient.

- I Want to Bring the Equipment to a Complete Standstill Quickly When Stopping.

Solution: Stepper motors with Fully Closed-loop Control for Submicron High Precision Positioning

In semiconductor manufacturing processes, where the trend toward miniaturization continues, improving alignment accuracy is an issue in some cases.

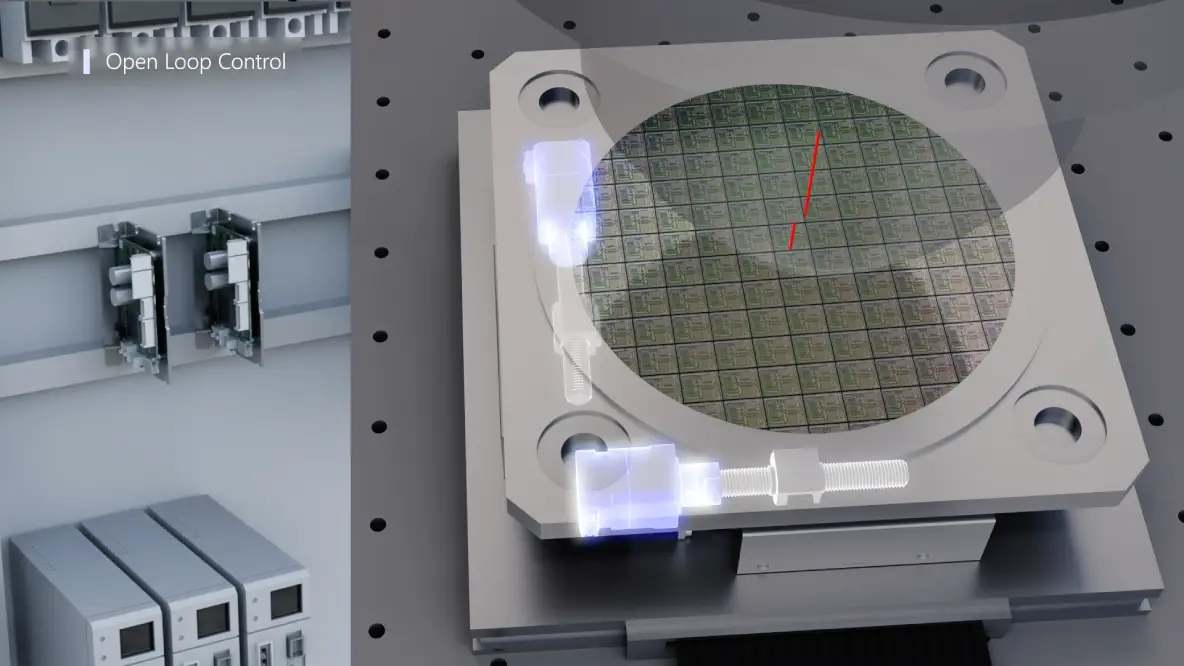

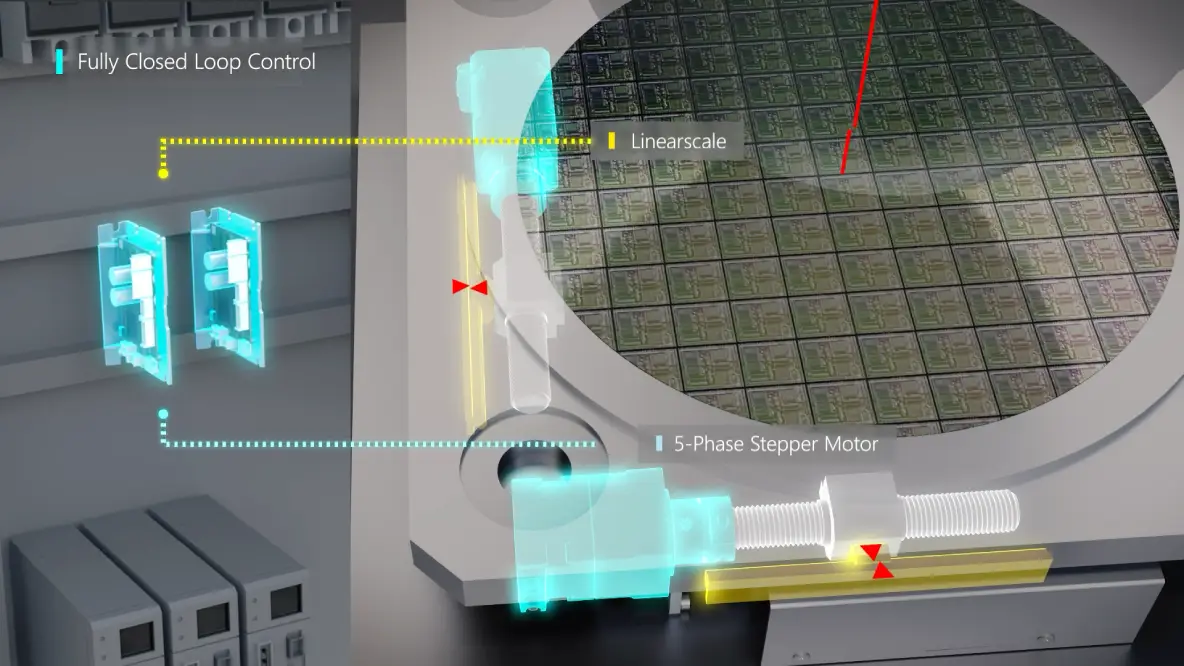

Fully closed-loop control of 5-phase stepper motors is possible with the CVD Series fully closed-loop control type. At the start of positioning, an open loop control taking advantage of the stepper motor's high responsiveness is performed, and once the position command is completed, position correction is performed using feedback from external sensors.

Fully Closed-loop Driver with Linear Encoder Support for Improved Accuracy

CVD Series fully closed-loop control type is compatible with linear encoders, allowing direct feedback of the position on the mechanism and correcting the difference between the feedback position and the command position. Enables high-precision positioning within submicrons, corresponding to the resolution of the linear encoder used in combination.

Image of High Precision Positioning by CVD Series Fully Closed-loop Control Type Compatible with Linear Encoders

Stepper Motor Prevents Hunting when Stopping

CVD Series fully closed-loop control type uses a stepper motor, so hunting does not occur when positioning is completed and the machine remains stationary. Additionally, there is no need for tailored gain adjustment as in the case of servo motors.

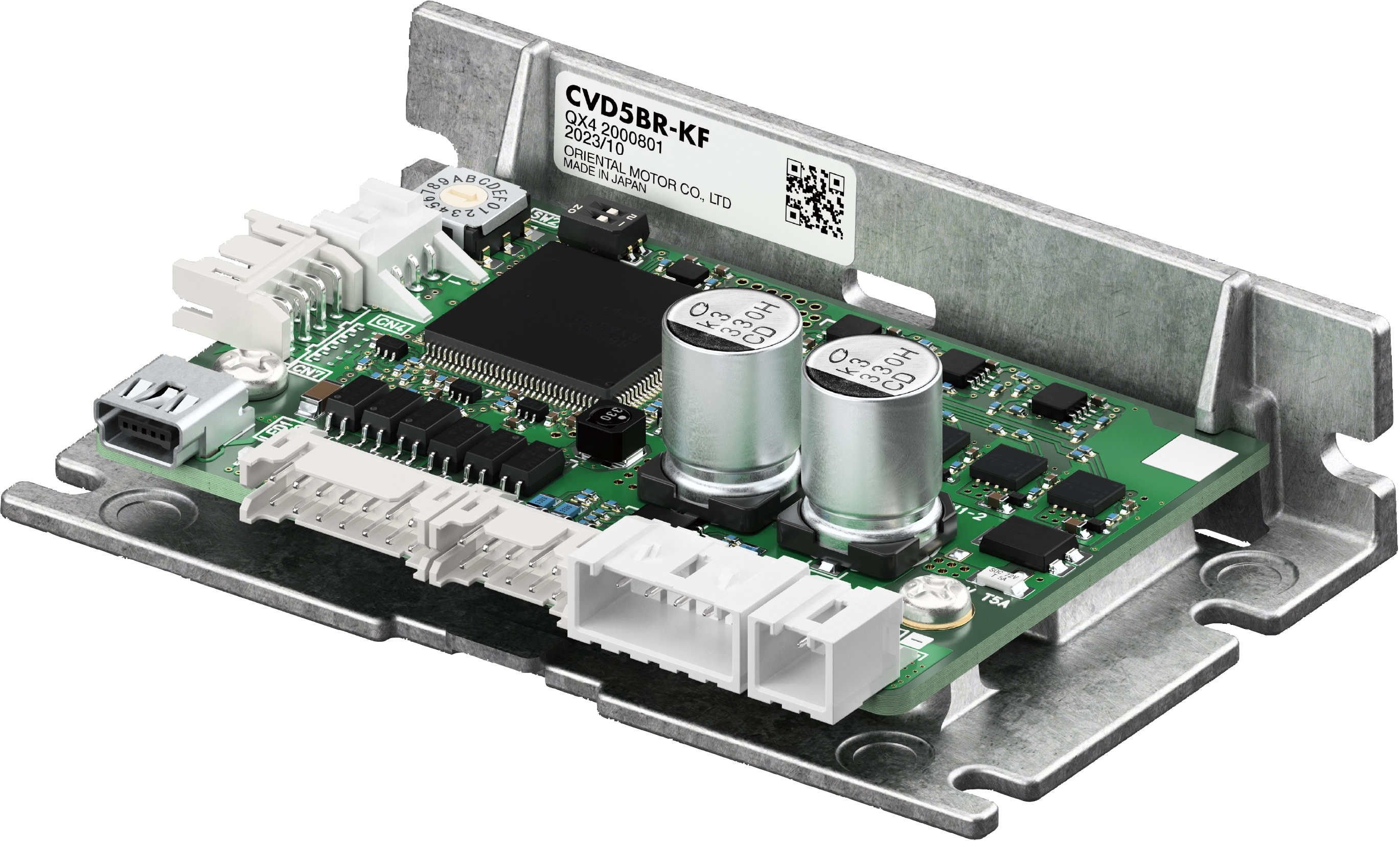

Achieve Cost Reduction and Driver Miniaturization with Fully Closed-loop Control

CVD Series is the industry's smallest class of compact, lightweight, high-performance drivers that help with space saving. The fully closed-loop control type can be used to configure a fully closed-loop control system at a reasonable price.

The connectors for wiring the driver come in products with different orientations, making them useful for wiring in tight spaces.

Product Proposal: CVD Series Fully Closed-Loop Control Type

Combinable Motors

- 5-phase Stepper Motor PKP Series

- 5-phase Stepper Motor PK Series