Case Study of Gripper (Load Gripping Mechanism) Load Size Determination

Issue

Determining the Size of the Incoming Load

Conventional Equipment

Equipment used in the process of determining the size of processed loads and sorting them.

Conventional Problems

- Using expensive CCD camera systems and measuring equipment is costly

Solution

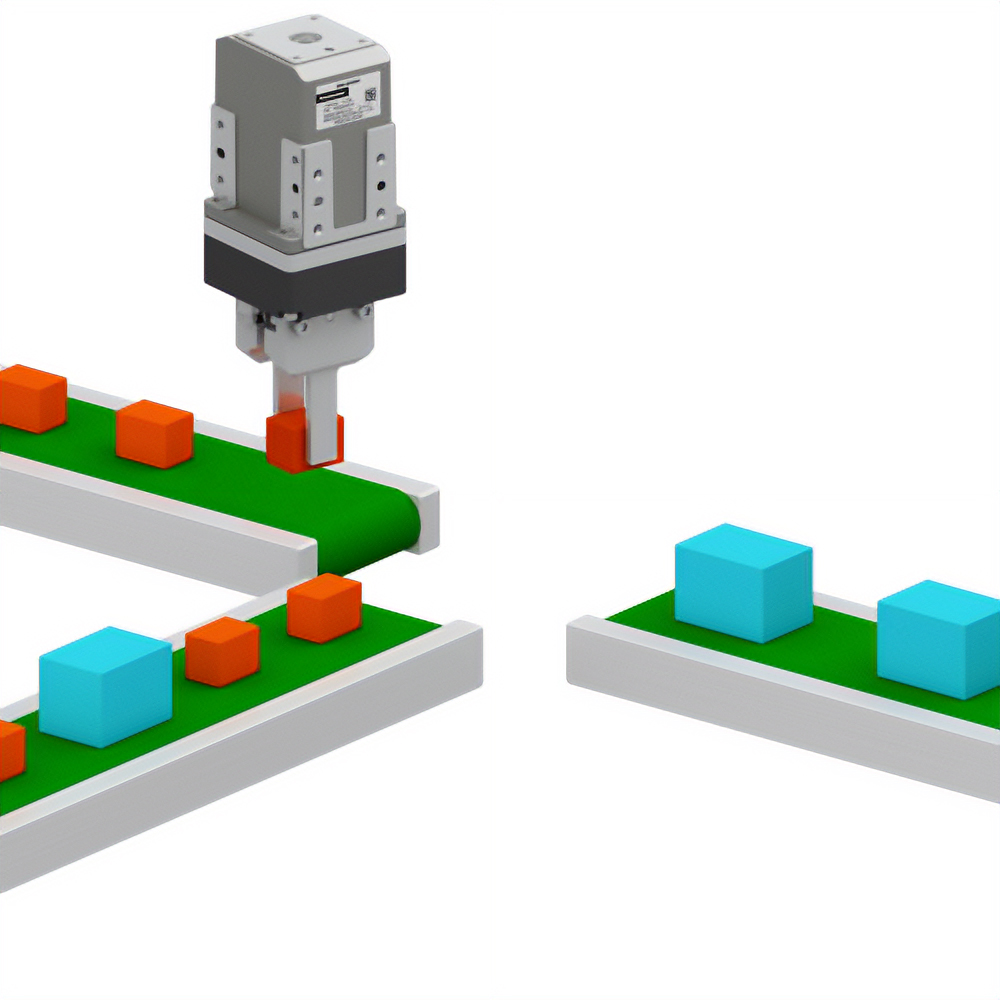

Electric Gripper EH Series

"AREA Output" and "TLC Output" Functions Enable Load Size Determination

The "push-motion operation" function of the EH Series electric gripper allows the size of the load to be determined without the need for expensive CCD camera systems or measuring equipment.

Specific Application Examples

Using the "AREA Output" and "TLC Output" from the driver, the size is determined just by gripping

By checking the operating range of the fingers by the output signal (TLC Output, AREA Output) from the driver, the size and presence of a load can be determined.

- ※

-

- AREA Output

- A signal that is output when the motor is in the set area

- TLC Output

- Output signal sent when output torque reaches the torque limiting value setting during push-motion operation

Achieving a Simple Gripper with Less Wiring

The AZ Series with a battery-free absolute encoder (ABZO Sensor) in the motor section eliminates the need for an external sensor. When used on moving parts such as the tip of a robot, problems such as broken sensor wires are eliminated. This leads to cost reduction because there is no need to use flexible cables.