Development for Concentric Shaft Gearbox of Parallel Gear Reduction Mechanism

This information is current as of April 28, 2022.

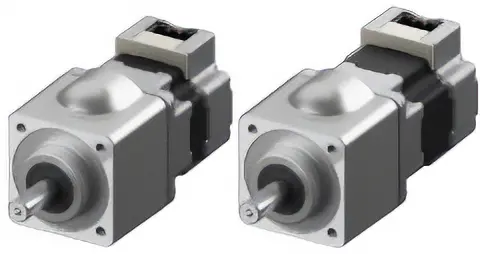

Oriental Motor's gearboxes having a conventional parallel gear reduction mechanism have a structure in which the output shaft of the gearbox (herein after referred to as gear output shaft) is offset from the center of the motor. The newly developed CS gearbox, however, has a parallel gear reduction mechanism, and also its gear output shaft is arranged to be concentric with the center of the motor. This makes it easier to design equipment such as a motor mounting plate. In addition, due to design innovation, the allowable torque and the permissible radial load have been significantly improved compared to conventional models. The CS gearbox is added to the line-up for the PKP Series 2-phase stepper motors and the BLH Series connector type brushless motors The following describes the structure and features of the CS gearbox.

Contents

- 1. Introduction

-

2. Parallel Shaft Gearboxes

- 2.1. Structure

- 2.2 Installing to Equipment

-

3. Concentric Shaft Gearboxes

- 3.1 Planetary Gear Reduction Mechanism

- 3.2 Development of CS Gearbox

- 3.2.1 Renewal of Structure for Parallel Shaft Gearbox

- 3.2.2 Curved Shape of Gear Case

- 3.2.3 Improvement of Bearing Support Structure

- 3.2.4 Improvement of Allowable Torque and Radial Load

- 3.2.5 Making Products Smaller and with Higher Torque

- 4. Summary

To read more, download and refer to the PDF file below.

1. Introduction

In the 1950s, when foot mounting type motors were the mainstream, Oriental Motor released easy-to-use flange mounting type motors. In 1951, we launched the H Series and promoted "standardization" of compact AC motors which frame size and mounting pitch were unified for each output power (see Figure 1). At the same time, in order to take advantages of the flange mounting type motors, we developed the dedicated parallel shaft gearboxes using a parallel gear reduction mechanism.

It is easy and common to interchange Oriental Motor's gearboxes to that with a different gear ratio since the frame size and the mounting pitch are compatible even in differentgear ratios (see Figure 2).

Afterward, Oriental Motor has evolved our motors into compact and high power motors. In accordance with evolution of motors, we have made eff orts to improve the performances of parallel shaft gearboxes in terms of high torque, high strength, long life, and low noise.

The conventional parallel shaft gearboxes have a structure in which the gear output shaft is off set from the motor output shaft.

To meet the market request, we have developed a concentric shaft gearbox (CS gearbox), which is a parallel shaft gearbox and also has a concentric structure of the motor output shaft and the gear output shaft (see Figures 3 and 4). The stepper motor PKP Series with frame size of 42 mm (CS geared type) received the Machinery and Robot Parts Award at the 2020 "Super" Monodzukuri Nippon Grand Parts Award. The following describes the structure and features of the CS gearbox.

CS Geared Type

CS Geared Type

The full text on this topic can be downloaded as a PDF.