Capper (Filling Machine) Case Study of Cost Cutting Without Torque Limiter

Issue

Making a Simple and Inexpensive Capper That Does Not Use a Torque Limiter

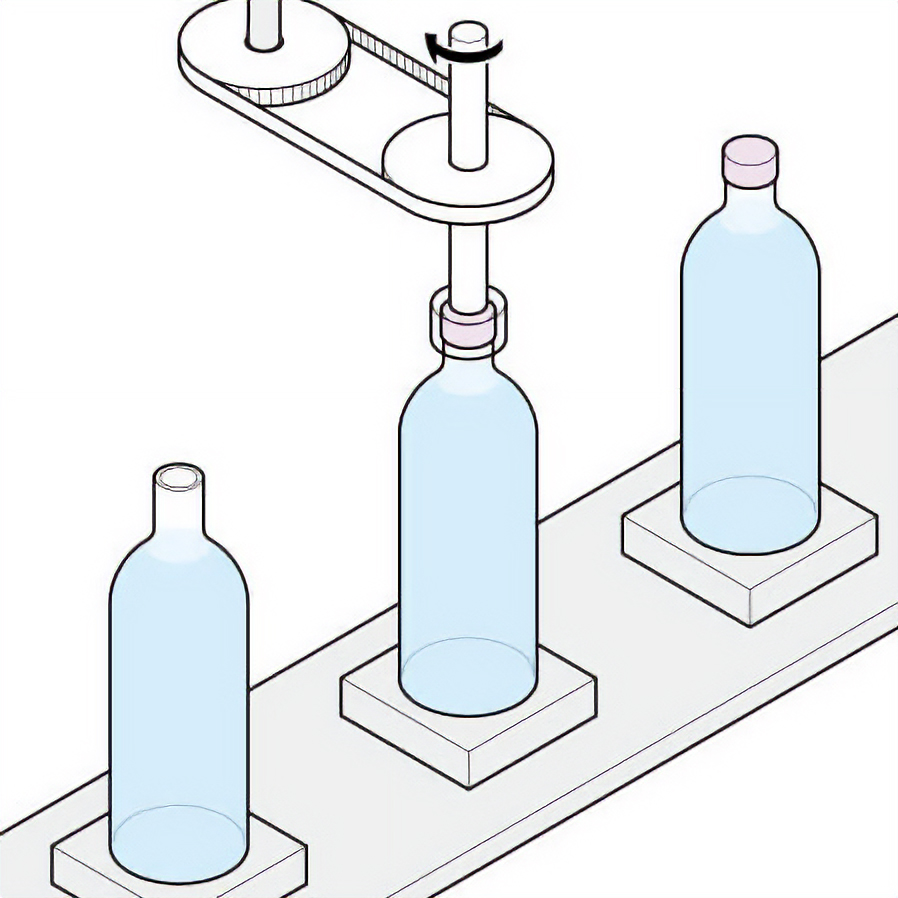

Conventional Equipment

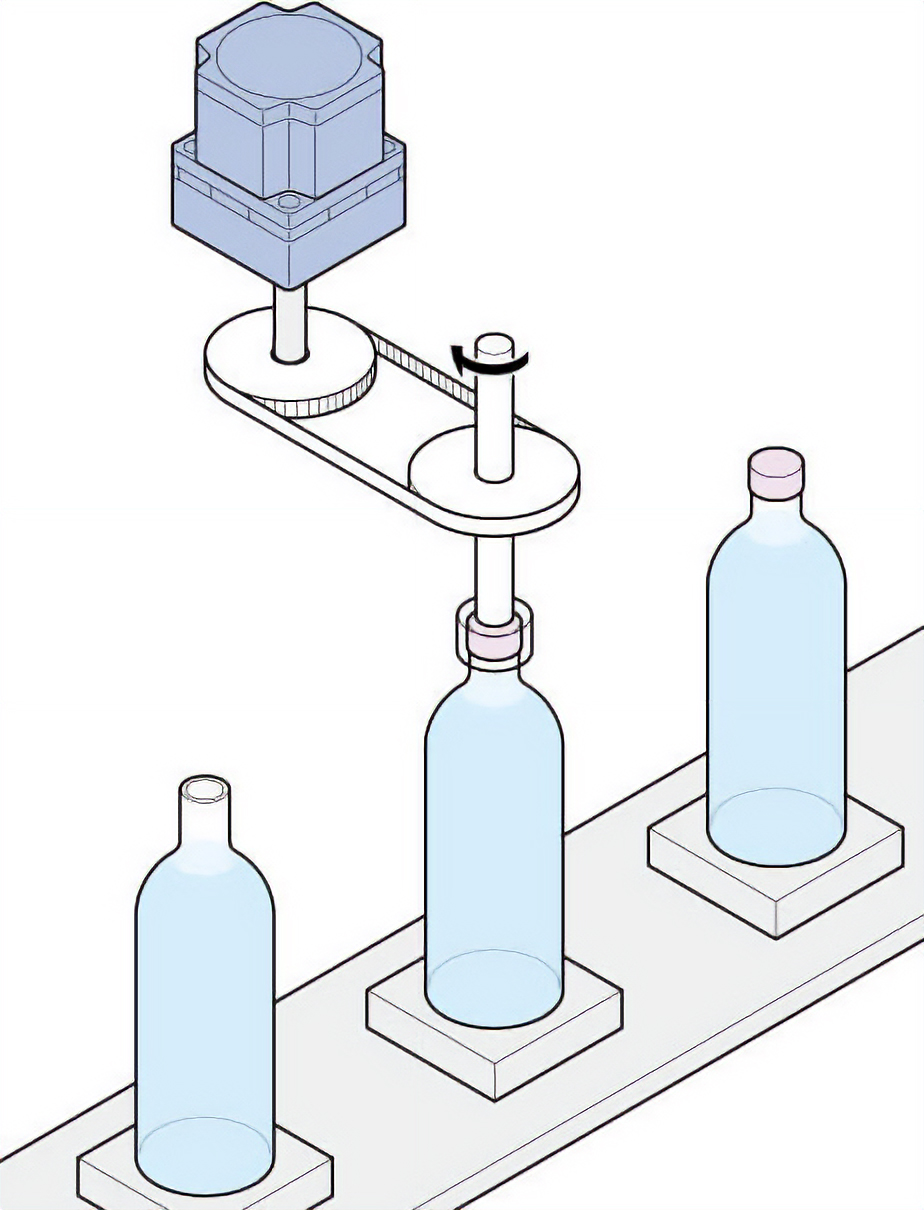

Equipment for tightening the caps of various containers to the appropriate torque after filling with products, which use an external torque limiter (magnetic clutch)

- Application

- Bottle cap tightening

Conventional Problems

- External parts such as torque limiters (magnetic clutches) are required to prevent damage to the cap due to over-tightening, which complicates the entire equipment and increases production costs

Solution

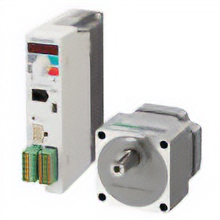

Brushless Motor BLE2 Series

The Need for Torque Limiters are Reduced by Utilizing the Torque Limiting Function

The need for torque limiters (magnetic clutches) can be reduced by using the Brushless Motor BLE2 Series with torque limiting function. No external parts are required, which simplifies equipment design and lowers production costs.

Specific Application Examples

Equipped with Electrical Torque Limiter "Torque Limiting Function"

The torque limiting function allows for setting the motor so that it does not generate more than the desired value of torque.

| Output Power | 30 W, 60 W, 120 W, 200 W, 400 W |

|---|---|

| Torque Limiting Setting Range*1 | 0~300 % |

| Number of points for a limiting value can be set | 16 Points |

| Torque Limiting Error*2 | ±10 % |

| Speed Control Range | 80~4000 r/min |

- *1

- The value when the rated torque value is 100 %

- *2

- An error of approximately ±10 % maximum (at rated torque and rated speed) may occur between the setting value and generated torque due to the setting speed, power supply voltage and motor cable extension distance.

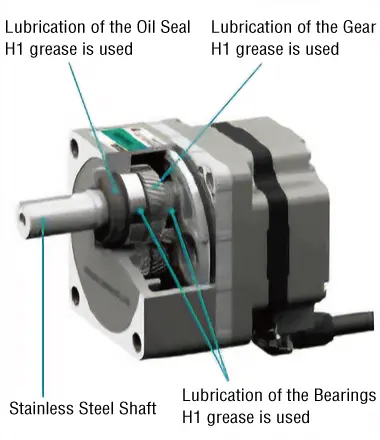

Product line of H1 food-grade lubricant compatible gearheads

For food cappers, gearheads with H1 food-grade lubricant are recommended.

What is H1 Food-Grade Lubricant?

A grease registered with the NSF in the category of "Lubricants usable in applications where accidental contact with food is possible."

What is NSF (NSF International)?

It is an international third-party certification body headquartered in the United States that provides global services related to public health and the environment, including standards development, product certification, auditing, education, and risk management.