Case Study of Space Saving via Direct Connection of Double-Row Belt Conveyor and Motor

Issue

Eliminating protrusions and wasteful space on the side of the conveyor

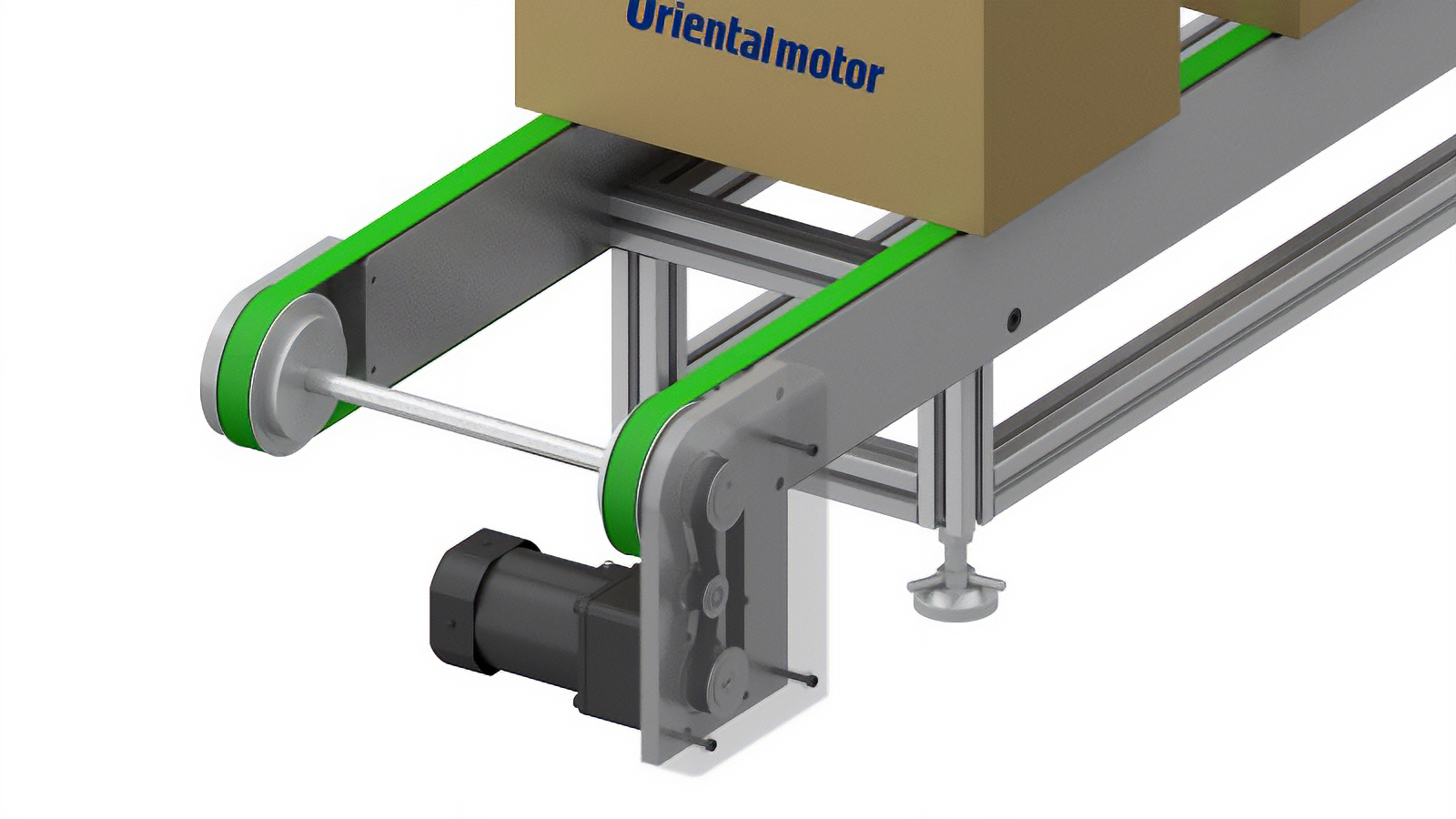

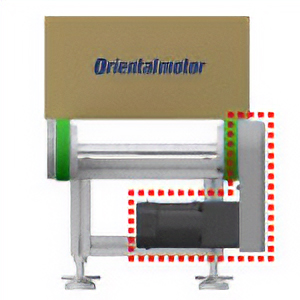

Conventional Equipment

A three-phase induction motor is installed underneath a 2-row belt conveyor, driven in connection with a timing belt-and-pulley mechanism (an inverter is used for speed control)

- Application

- Transportation of cardboard cases

Conventional Problems

- Transfer mechanism protrudes from the side of the conveyor, creating extra space

- Since it’s a slim conveyor that can be used in small spaces, you don't want to take up extra space in the width and bottom

- Many parts are required to install the equipment, increasing the overall labor for assembly

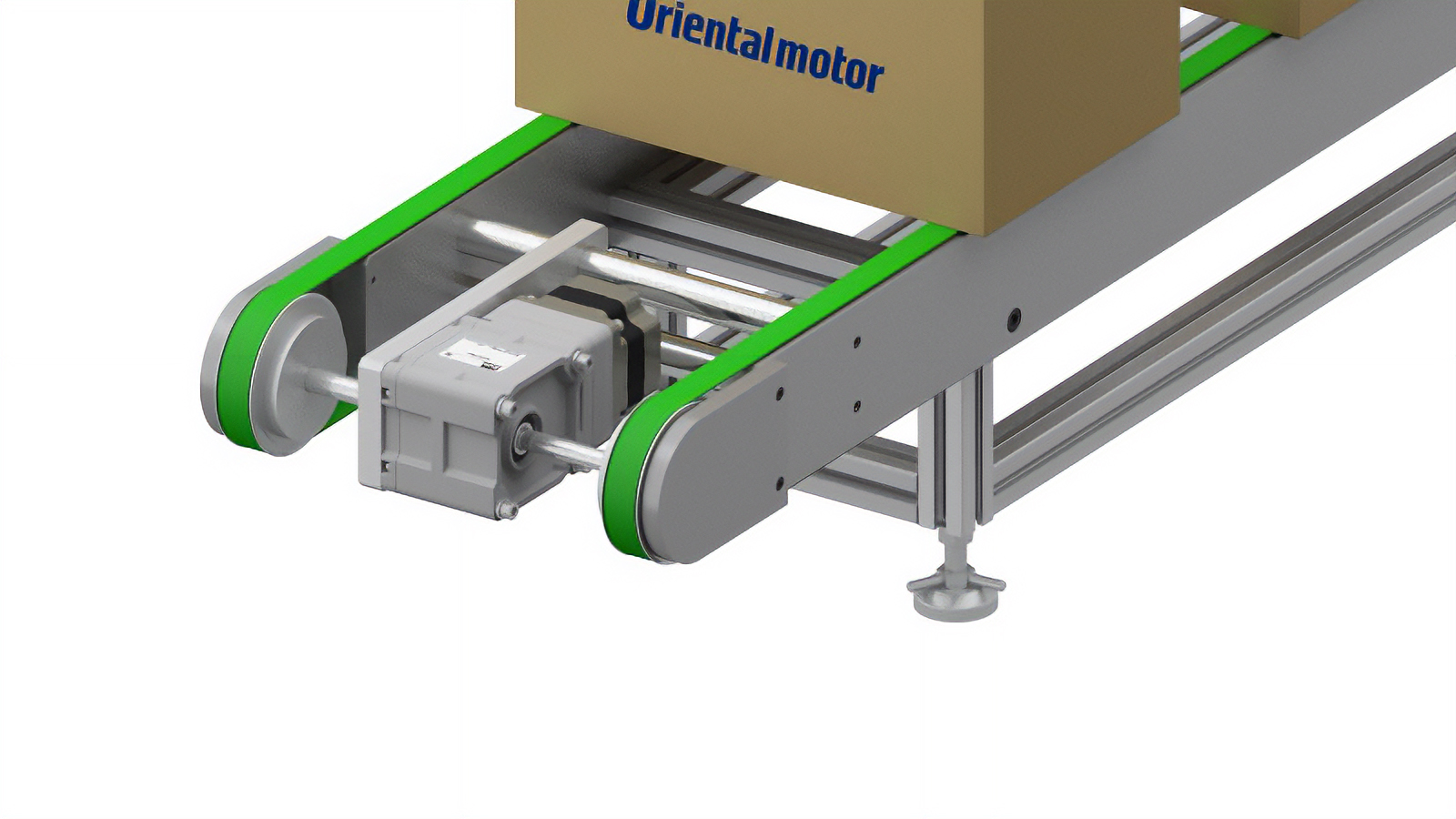

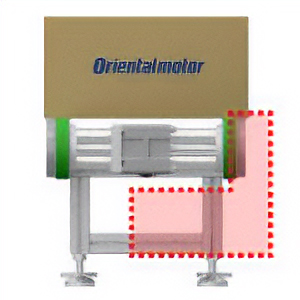

Solution

Brushless Motor BMU Series

with JH gearheads (right-angle gearheads)

for slimmer and space saving conveyors

The motor is installed between 2 rows of conveyors and uses the BMU Series of compact, high power brushless motors and right-angle hollow shaft hypoid JH gearheads of high strength and high permissible torque. This eliminates the protrusion and extra space on the sides and bottom of the conveyor, allowing for significant space savings.

Specific Application Examples

- Right-angle hollow shaft hypoid JH gearheads with high strength and high permissible torque are used

- A motor is installed between 2 rows of conveyors, and conveyor drive rollers are attached to both ends of the load shaft

- Left and right conveyors are driven via load shaft

Total cost reduction by reducing unnecessary space and number of parts

It saves space for motors and transfer mechanisms, reducing design time, assembly time, and time for parts ordering and management.

| Conventional Equipment | When a JH Gearhead is Used | |

|---|---|---|

| Equipment width and height on the side of the conveyor |

|

width and space at the bottom are reduced, slimming down the equipment |

| Minimum number of parts required |

|

|