Electric Actuator

Prodotti che integrano motori con viti a ricircolo di sfere e altri componenti meccanici. Non richiedono assemblaggi o regolazioni da parte del cliente. Questi prodotti ottimizzano l'efficienza della progettazione e riducono i tempi di produzione.

Electric Actuator

Overview and Related Information

Overview

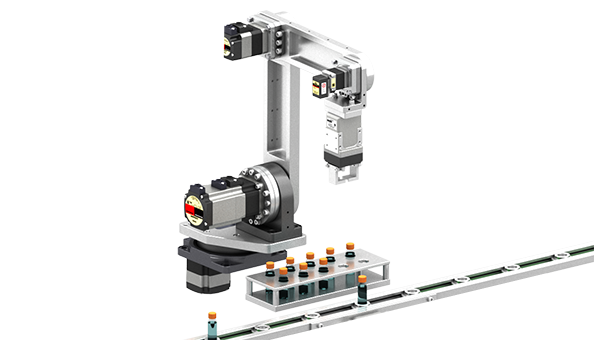

An electric actuator is a product that combines a motor with mechanical components.

Their excellent controllability means motors are often used in combination with mechanical components such as ball screws, belt-and-pulleys, and rack-and-pinions to provide drive sources for a variety of automated equipment.

Oriental Motor has a range of electric actuators, consisting of motors and mechanical components, to meet the needs of various automated equipment.

Features

Equipped with a motor that provides excellent controllability, the electric actuators offer the following advantages over hydraulic and pneumatic actuators.

- The actuator is very stable when operated, even at low speeds. It also offers smooth acceleration and deceleration operation.

- Operations can be programmed with multiple stopping points.

- With an electric actuator that uses a stepper motor and servo motor, position and speed regulation can be performed easily using data.

Setup change is also simple, as all that needs to be done is changing the data.

Advantages

When automated equipment is designed, various factors must be taken into consideration including the production line layout, installation environment, ease of maintenance, configuration of electrical wiring and control system, and so on.

This means many man-hours are needed to select the motor and other mechanical components and to create a parts list, drawings, operating manuals, and so forth.

Oriental Motor offers various electric actuators to help improve the productivity of design work.

Use of electric actuators offers the benefits explained below.

Higher Design Efficiency

The primary feature of automated equipment is their ability to implement a series of basic operations such as "transfer", "push" and "rotate". By combining electric actuators to produce automated equipment, you can save time in design.

Shorter Production Time and Higher Quality

When building equipment in-house by assembling a motor and mechanical components, the quality of assembly affects the traveling resistance and position accuracy. Therefore, adjustments will be needed. In comparison, Oriental Motor electric actuators are guaranteed to provide the specified operating performance. Using them reduces adjustment work and ensures uniform quality.

Types and Applications

[Load and Rotate] Hollow Rotary Actuator

This actuator is ideal for index drive applications combining a motor with a rotary table mechanism.

![[Load and Rotate] Hollow Rotary Actuator](/sites/default/files/image/products/electric-actuators/overview/electric-actuators-overview_13.webp)

-

Positioning a Table

-

Transporting by Arm

[Push and Transport] Compact Electric Cylinder

This product features a stepper motor integrated with a ball screw. This is an ideal actuator for pushing and pulling small loads or fine-tuning applications.

![[Push and Transport] Compact Electric Cylinder](/sites/default/files/image/products/electric-actuators/overview/electric-actuators-overview_10.webp)

-

Focusing of a CCD Camera

-

Driving an XY Stage

(Automated micrometer head)

[Push to Carry] Mounting Adapter for Linear Actuator

A linear motion mechanism with a lead screw and plastic nut that can be mounted without coupling to a stepper motor.

![[Push to Carry] Mounting Adapter for Linear Actuator](/sites/default/files/image/products/electric-actuators/overview/electric-actuators-overview_19.webp)

-

Syringe Pump

-

Test Tube Transportation

[Push and Transport] Electric Cylinder

The motor is combined with a linear motion mechanism. This is an ideal actuator for pushing and pulling loads.

![[Push and Transport] Electric Cylinder](/sites/default/files/image/products/electric-actuators/overview/electric-actuators-overview_07.webp)

[Load and Transport] Electric Linear Slide

This actuator combines a motor with a linear motion mechanism, making it ideal for transporting loads.

![[Load and Transport] Electric Linear Slide](/sites/default/files/image/products/electric-actuators/overview/electric-actuators-overview_04.webp)

-

Tightening of Parts

-

Moving a CCD Camera

[Push and Transport] Rack-and-Pinion System

This is an actuator that combines a motor with a rack-and-pinion mechanism. This product offers 2 types, parallel and vertical, for flexible mounting.

![[Push and Transport] Rack-and-Pinion System](/sites/default/files/image/products/electric-actuators/overview/electric-actuators-overview_16.webp)

-

Sorting of Transported Goods

-

Vertical Operation

For Those Who Have Not Decided on a Series

View More About the Selection Guide

Selection Guide

This selection guide will help you find the product series best suited for your equipment. Select an equipment application example and follow the guidance to select a product series.

Learn More

View More about the Problem Solving Case Studies

Problem Solving Case Studies

Here is the information on the solutions for your equipment issues. We introduce examples of in-house production of equipment used in actual manufacturing sites, as well as application examples of our recommended products to solve the issues with conventional equipment.

Learn More