Rack-and-Pinion System

L Series

αSTEP AZ Series Equipped

- A Structure That Integrates a Rack-and-Pinion Mechanism with a Stepper Motor

- Equipped with Closed Loop Stepper Motor

- Stroke 100 to 1000 mm

- Maximum Transportable Mass 100 kg

Features | Rack-and-Pinion System L Series αSTEP AZ Series Equipped

Key Features

Compact Size and Maximum Transportable Mass of 100 kg

Maximum Transportable Mass 100 kg

Larger-diameter pinion with increased gear strength realizes a maximum transportable mass of 100 kg

Maximum Stroke 1000 mm

Product line includes strokes from 100~1000 mm

Comparison With Electric Linear Slide

The rack-and-pinion system can transport the transportable mass if it is mounted without consideration of the moment of inertia.

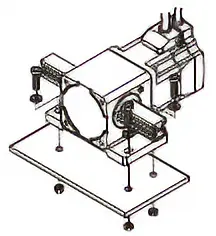

Overview of Rack-and-Pinion System

The rack-and-pinion system can easily convert the rotation of the motor into linear motion.

Although the linear motion mechanism part is compact in design, it can transport a large load due to its high strength processing.

Contributing to Design Efficiency

Reduces Startup Time

The rack-and-pinion system reduces the number of components traditionally used, significantly reducing the man-hours required for design and assembly.

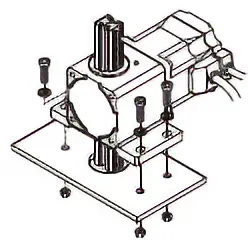

Space Saving

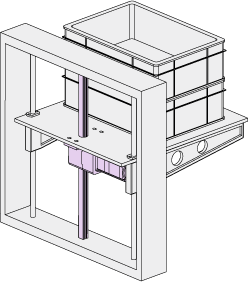

By fixing the screw holes on both ends of the rack, the main unit can be self-propelled. This function is effective for equipment that is too small to provide motor space.

Allows Setting in mm Units

αSTEP AZ Series is used for the drive motor.

Using together with the MEXE02 support software makes setting travel amount in mm units easy, allowing for a variety of linear motion applications.

Minimum Travel Amount

| High-Speed Type | Large Transportable Mass Type |

|---|---|

| 0.01 mm | 0.001 mm |

Operating Speed Range (For AC input type)

| High-Speed Type | Large Transportable Mass Type | |

|---|---|---|

| Frame Size 60 mm | Frame Size 80 mm | |

| 0~500 mm/s | 0~90 mm/s | 0~40 mm/s |

Applications

The rack-and-pinion system, which can be applied to a variety of applications, is a user-friendly product that can be selected as if it were a component.

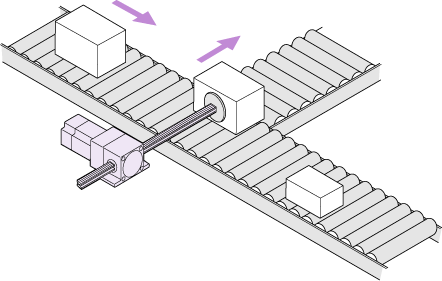

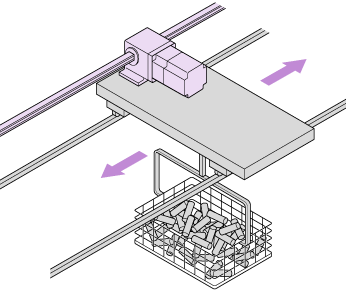

| Rack Moving Direction | Motor Fixed | Rack Fixed |

|---|---|---|

Parallel (B type) |

Easily move objects by pushing or pulling. |

A wide variety of stroke and speed is available. |

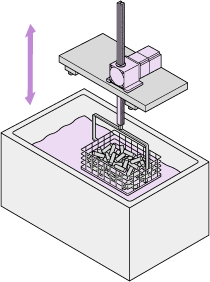

Vertical (F type) |

Vertical operation is also easy. Electromagnetic brake drop protection is also available. |

Using the screw holes at the end of rack simplifies the fastening of loads and rack fixing. |

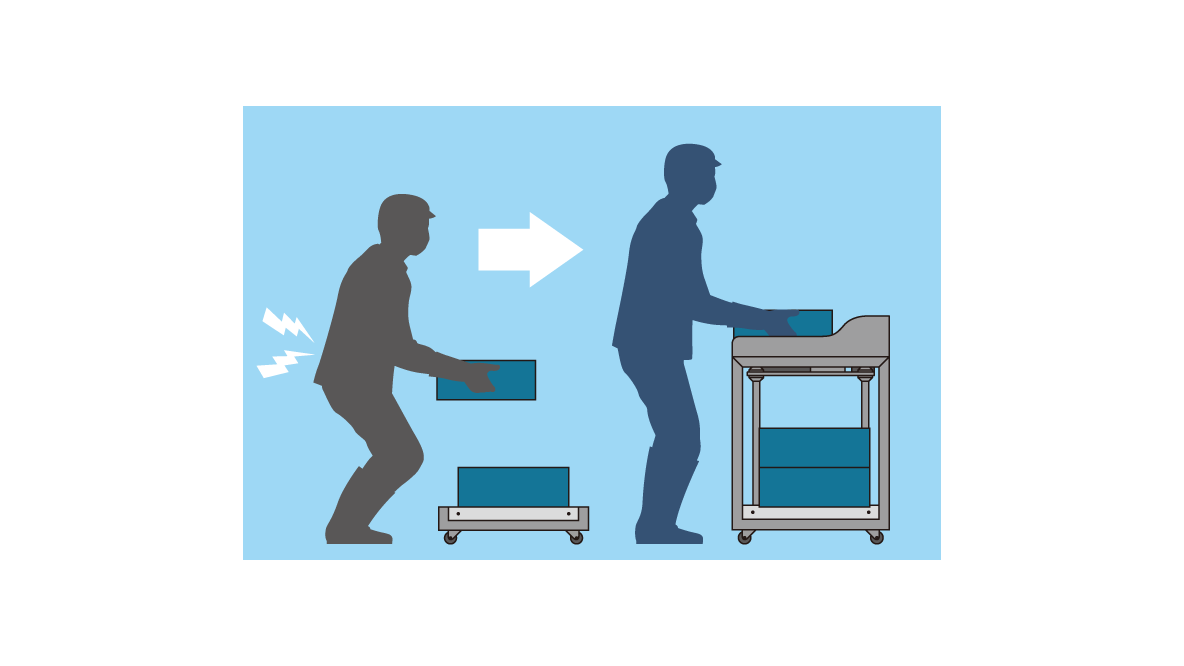

Labor-Saving Ideas

At Japan's Manufacturing sites, labor shortages due to a decline in the working population associated with the decreasing birthrate and aging population is becoming an issue. Amidst this, there is an urgent need for labor-saving that reduces the burden of "heavy lifting work" and "repetitive work such as sorting." Rack-and-pinion system that transports high loads contributing to labor-saving in manufacturing operations.

Advantages of AZ Series Equipped

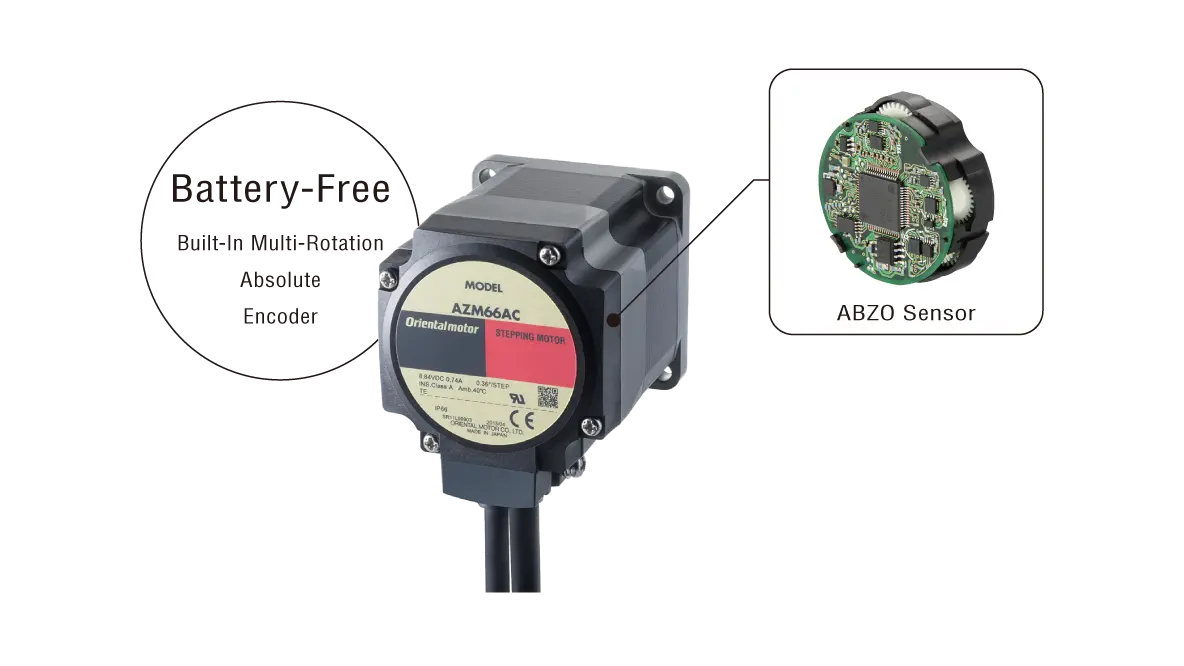

Encoder assoluto senza batteria

È dotato di un piccolo encoder assoluto meccanico senza batteria (sensore ABZO). In questo modo è possibile migliorare la produttività e ridurre i costi.

- Sensore meccanico

Conserva le informazioni sul posizionamento anche in assenza di alimentazione - Encoder assoluto multigiro

Il rilevamento della posizione assoluta è possibile con ±900 (1.800) giri dell'albero motore dalla posizione iniziale

Non è richiesto alcun sensore esterno

Poiché si tratta di un sistema assoluto, non sono richiesti sensori homing o sensori di limite.

Vantaggi

- Miglioramento dell’homing ad alta velocità e della precisione di homing

- Costi ridotti

- Cablaggio semplice

- Non influenzato dal malfunzionamento del sensore esterno

Senza batteria

I sensori meccanici non richiedono batterie.

Le informazioni di posizionamento sono gestite meccanicamente dal sensore ABZO.

Vantaggi

- Non è necessario sostituire le batterie

- Possibilità illimitate di installazione dei driver

- Adatto alla spedizione all'estero

Semplificazione del programma principale tramite la funzione sequenza

La Serie AZ è dotata di una vasta gamma di funzioni di sequenza, come impostazioni del timer per operazioni collegate e durante le operazioni, istruzioni condizionali e operazioni in loop (esclusi alcuni modelli).

Può essere configurata utilizzando il software di supporto MEXE02, che semplifica il programma di sequenza del sistema host.

- Valore di configurazione dei dati di posizionamento (max. 256)

- Segnali di I/O fisici per uso generale (Ingresso 10, Uscita 6)

- Segnali di I/O remoti (Ingresso 16, Uscita 16)

Return-to-Home Not Required (Built-in controller type)

Even if the power shuts down during a positioning operation, the position information is retained. With the built-in controller type, the positioning operation can be restarted without performing return-to-home, after an emergency stop on the production line or a blackout.

Data Collection of Motor Operation Status and Functions Useful for Preventive and Predictive Maintenance

This software is equipped with various monitoring functions for checking the operating status of the motor.

By using different types of equipment for different situations, it is possible to shorten the start-up and adjustment time of the equipment, as well as to utilize it for maintenance and servicing.

Monitoring Function to Visualize the Motor Operating Status and Help Collect Data

The ABZO sensor bulit in the AZ Series allows you to monitor the motor's operating status numerically.

[Monitoring With MEXE02 Support Software]

In addition, the built-in controller type can realize data collection at a host master via industrial network.

Information Functions Useful for Preventive and Predictive Maintenance

By setting arbitrary numerical values for the monitored information items, external signals can be output when the values are reached.

Importing this information into the host controller helps in early detection of problems and adjustment of product maintenance timing.

Examples of Information Functions

TRIP Information

You can set the number of rotations you want to output in advance, and output when that number is reached. (Motor operation will continue)

Temperature Information

You can set the desired output temperature in advance, and the driver will output when it reaches that temperature. (Motor operation will continue)

Standardized Wiring, Control, and Maintenance Parts

Various actuator products equipped with the αSTEP AZ Series are available.

Each of them has the same motor and driver, for standardized wiring, control, and maintenance parts.

Wiring Standardization

The wiring for motor cables, I/O signals, and power supply is the same.

Control Standardization

These products can be operated via the same method, since the control method is the same. For the network control, the remote I/O and the command code are also the same. It saves you the trouble of creating a program.

Unification of Maintenance Parts

Maintenance parts can be minimized, since the motor, driver, and cable are common to all. Management costs (parts cost, management space) can be reduced.

AZ Series-Equipped Product Line

Electric Actuators (AZ Series Equipped)

| Electric Linear Slides | Electric Cylinders | Compact Electric Cylinders | Rack-and-Pinion System | Electric Grippers | Hollow Rotary Actuators |

|---|---|---|---|---|---|

| EZS Series | EAC Series | DR Series DRS2 Series |

L Series | EH Series | DGII Series |

- The power supply input of the installed motor differs between Series. Please refer to each series page for the detailed product line.

Driver Features and Product Line

Drivers That Can be Selected to Match the Host Controller

| Driver Type | Compatible Interfaces | Single Axis Driver | ||

|---|---|---|---|---|

| AC Input | DC Input | |||

|

|

|||

| Network Compatible | Drivers are controlled directly from a host control device through industrial network | EtherCAT | ○ | ○ |

| EtherNet/IP™ | ○ | ○ | ||

| PROFINET | ○ | ○ | ||

| Built-in Controller | Operation data is built into the driver. Controllable via Modbus (RTU) and I/O. |

Modbus (RTU) I/O |

○ | ○ |

| Pulse Input with RS-485 Communication | Controlled by pulse signal. Motor status information can be monitored via Modbus (RTU). | Pulse input Modbus (RTU) |

○ | ○ |

| Pulse Input | Controlled by pulse signal | Pulse input | ○ | ○ |

- DC input mini drivers and multi-axis driver lineups are also available.

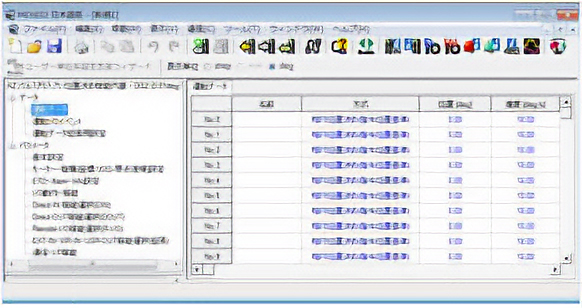

Facile gestione da PC con software di supporto MEXE02

Utilizzando il software di supporto MEXE02, è possibile impostare e modificare i dati di funzionamento e vari parametri, nonché gestire e monitorare varie condizioni.

Fare clic qui per scaricare il software di supporto

Supporto completo dall'avvio alla manutenzione con una varietà di funzioni

-

Avvio e diagnostica

Vengono fornite funzioni utili per il controllo del cablaggio e il funzionamento del test.

- Impostazione e salvataggio dei dati di funzionamento

- Monitoraggio I/O

- Teaching, funzionamento da remoto

-

Regolazione

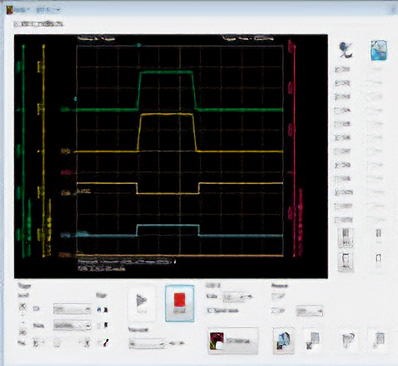

Di seguito sono riportate le funzioni che possono aiutare a regolare il funzionamento del motore dopo l'installazione dell'apparecchiatura.

- Oscilloscopio

-

Diagnosi e manutenzione

Le funzioni di diagnosi e manutenzione sono disponibili per risolvere i problemi e per intervenire dopo l'avvio del funzionamento.

- Monitor dell’allarme

- Monitor informazioni dell’unità

- Monitor dello stato

-

Schermo di configurazione dei dati di funzionamento/parametri -

Oscilloscopio

Fare clic qui per i dettagli sulle funzioni del software di supporto

Product Line

Please purchase the rack and pinion motor, driver and connection cable separately.

L Series AZ Series Equipped

| Rack Moving Direction | Frame Size [mm] |

Type | Power Supply Input | Transportable Mass [kg] |

Operating Speed Range [mm/s] |

Stroke [mm] |

Motor | Electromagnetic Brake |

|---|---|---|---|---|---|---|---|---|

|

|

60 | High speed | AC | 7 | 0 to 500 | 100 to 800 | AZM66 | Not Equipped/Equipped |

| 10 | 0 to 250 | |||||||

| DC | 5 | 0 to 200 | 100 to 500 | |||||

| 10 | 0 to 100 | |||||||

| Large transportable mass | AC | 30 | 0 to 90 | 100 to 800 | ||||

| DC | 0 to 50 | 100 to 500 | ||||||

| 80 | High speed | AC | 7 | 0 to 500 | 100 to 1,000 | |||

| 20 | 0 to 250 | |||||||

| DC | 7 | 0 to 150 | ||||||

| 20 | 0 to 60 | |||||||

| Large transportable mass | AC | 70 | 0 to 40 | |||||

| 100 | 0 to 20 | |||||||

| DC | 50 | 0 to 20 | ||||||

| 100 | 0 to 10 |

Drivers

| Driver Type | Power Supply Input [V] |

|

|---|---|---|

| Built-In Controller | Single-Phase 100-120 Single-Phase/Three-Phase 200-240 DC24/48 |

|

| Pulse Input With RS-485 Communication | ||

| Pulse Input | ||

| EtherCAT Compatible | ||

| EtherNet/IP Compatible | ||

| PROFINET Compatible |

Connection Cable Sets/Flexible Connection Cable Sets

- Motor cable from motor cannot be connected directly to driver. Find the right connection cable.

- Use flexible connection cables for applications where cables are bent.

| Length [m] |

|

|---|---|

|

0.5~20 |

|

Related Products

Driver multiasse Serie AZ per Alimentazione DC

È possibile collegare i motori con alimentazione DC della Serie AZ Oriental Motor e gli attuatori elettrici dotati di tali motori.

-

Modello a 2 assi -

Modello a 3 assi -

Modello a 4 assi

Mini driver Serie AZ per Alimentazione DC

Si tratta di un mini driver progettato per essere più compatto e leggero dei driver standard. Compatibile anche con l'alimentazione a batteria, è quindi utilizzabile per una gamma di applicazioni ancora più ampia rispetto al passato.

Narrow down Products