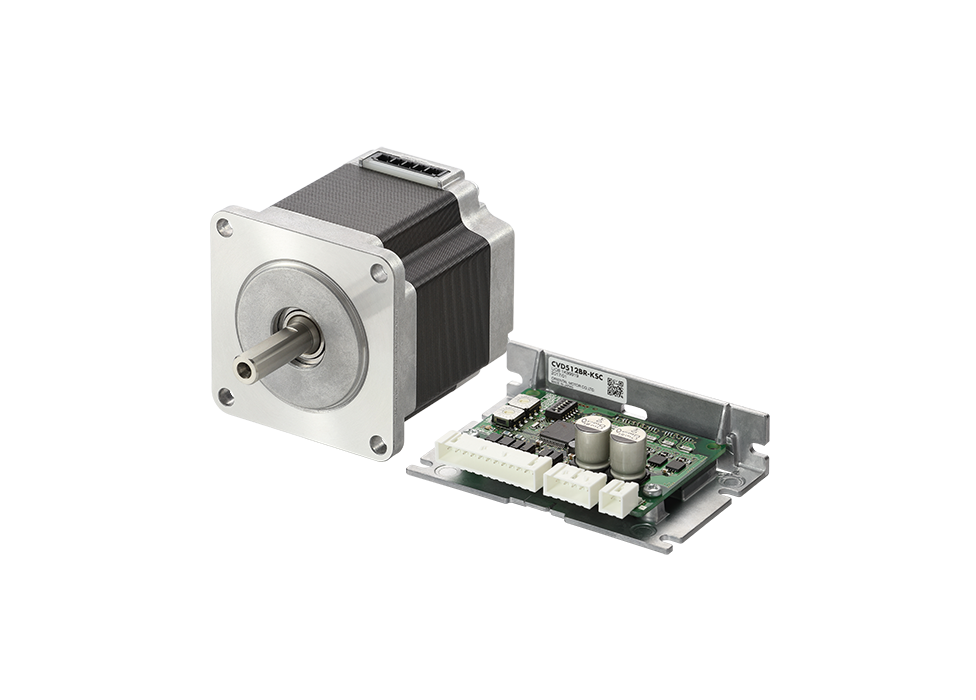

Stepper Motor PKP Series/

CVD Series SC Type Driver

- Adopts a stepper motor

- Speed control is possible without using a pulse oscillator

- Small size and high torque

- Speed control range 0.02 to 600 r/min

Features | Stepper Motors PKP Series/CVD Series SC-Type Driver

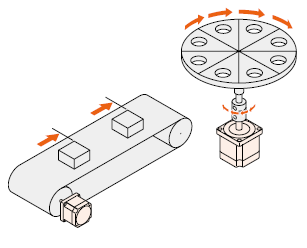

Recommended for the Following Applications

-

Regular Feed Operation

Operation by turning the forward input ON and OFF is possible.

-

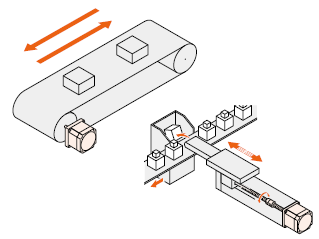

Back-and-Forth Operation

Operation by turning the forward/reverse input ON and OFF is possible

-

2-Speed Switching Operation

2-Speed Switching Operation is possible

-

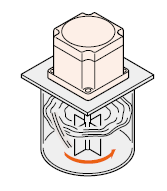

Smooth Low Speed Operation

Speed range is from 0.02 r/min to 600 r/min

Pulse generator not required. Simple System Configuration Realized by I/O Control

Simple configuration with only motor, driver, and programmable controller. The operating speed, acceleration/deceleration time and operating current are set by driver switches, and the FWD (RVS) input is simply turned ON and OFF. Simple speed control with the performance of a speed control motor is possible.

2 Different Speeds Can be Set

The driver can be set to 2 different speeds and switched externally.

Speed Setting Range: 0.02 r/min~600 r/min

-

Back-and-Forth Operation

-

2-Speed Switching Operation

Contributing to Motor Downsizing and Equipment Miniaturization

Due to the low speed operation and high torque of the stepper motors, they can be used without gearheads. Enables downsizing of motors and miniaturization of equipment. Enables driving with a motor about half the size of an induction motor, but which has almost the same rotation speed.

Improved Repeatability of Stopping Position Due to Constant Overrun Amount When Operation Input is OFF

When the motor is stopped, the deceleration travel amount will not change due to load inertia or frictional load under the same operation conditions, even if the load weight changes. This improves the repeatability of the stop position.

Holding Torque Even at Motor Standstill

Even when the motor is stopped, current is supplied to the motor, which generates torque. Therefore, it can hold the load (holding force is 50 % of the maximum holding torque).

Product Line

The motor, driver, and connection cable can be purchased individually.

(When the screen transitions upon selecting motor frame size, the names of the motor, driver, and connection cable, each associated with a "+," will be displayed as a candidate.)

| Frame Size [mm] |

Maximum Holding Torque [N·m] |

Setting Speed Range [r/min] |

|---|---|---|

| 28 | 0.052~0.091 | 0.02~600 |

| 42 | 0.22~0.5 | |

| 60 | 0.66~2.1 |

Related Products

Brushless Motor BLH Series

Achieves excellent speed stability of speed regulation with respect to the load of ±0.5 % max. In addition to potentiometer setting, speed setting by external DC voltage is possible. You can choose from a wide range of products.

Speed Control Range :100 (80)~3000 r/min

Stepper Motor PKP Series/

CVD Series Pulse Input Driver

You want to operate a stepper motor easily by pulse input. This is a motor and pulse input driver that meets such needs. In pursuit of high efficiency, high torque, and low vibration, even better performance has been achieved.

Stepper Motors PKP Series/CVD Series RS-485 Communication Type Driver

You want to run a stepper motor under Modbus (RTU) control. You want to set data easily on a touch screen. This product combines a motor with a RS-485 communication compatible driver to meet such needs. Up to 31 axes of drivers can be controlled by connecting them to a single host control device.

Narrow down Products