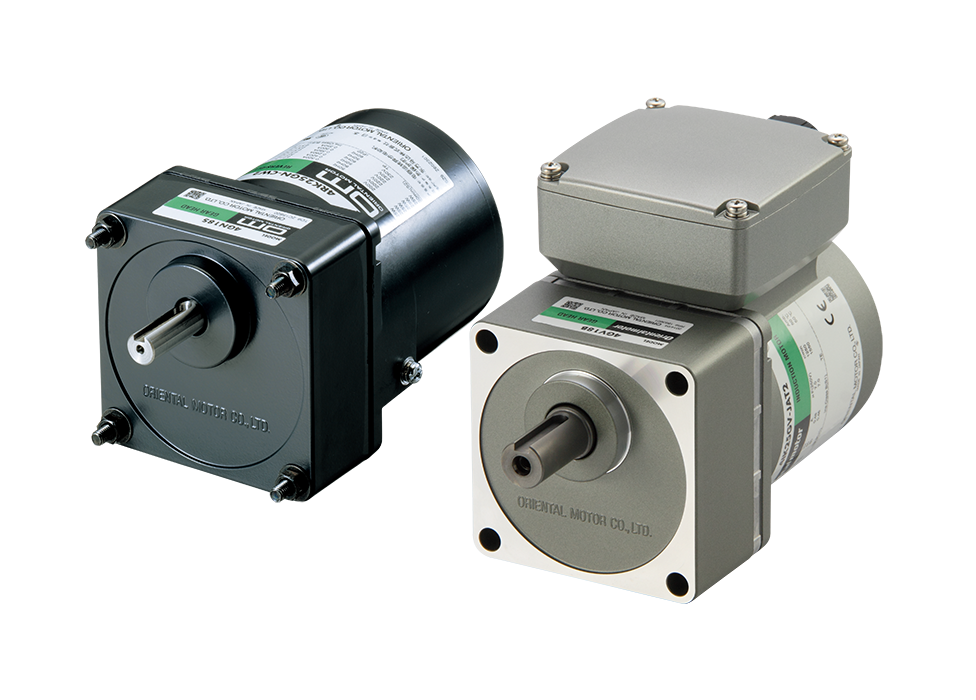

Induction Motors

- Ideal for applications requiring continuous operation in one direction

- We also offer three-phase high efficiency motors for inverter control

- Output Power 1 to 200 W

Features | Induction Motors

Induction Motor Features

Ideal for Unidirectional and Continuous Operation

Ideal for applications that operate continuously in one direction, such as conveyor drives and rotary tables.

Easy Operation

All you need is to connect a capacitor and plug the motor into an AC power supply, and the motor can be easily operated.

(A capacitor is not required for three-phase motors.)

Conforms to International Safety Standards

All models conform to various safety standards and have built-in overheat protective devices.

Applicable Standards

UL/CSA Standards certified

Component certified under the China Compulsory Certification System (CCC System)

Implemented CE Marking (Low Voltage Directive)

Motor Overheat Protective Device

Thermal protector,

impedance protected

Three-Phase High Efficiency Motors With Optimized Design Are Also Available

A review of the basic motor design has yielded unprecedented high efficiency and energy savings.

Also available are three-phase high efficiency motors with characteristics best suited for speed control by inverters, enabling energy saving.

KIIS Series

-

Maximum Efficiency of 80 %

Specialized components and an optimal magnetic design are used to make high efficiency three-phase motors with a max. efficiency of 80 %. Motors are fanless with increased motor output power, and significant loss reduction.

Comparison of Maximum Efficiency (Reference values)

[Rated Output Power at 60 Hz]

- *Three-Phase 380/400/415 VAC meets IE3 reference values.

IE4 and IE3 are efficiency classes under the international standard IEC 60034-30-1.

- *Three-Phase 380/400/415 VAC meets IE3 reference values.

-

Fanless

With reduced loss, there is less heat generation in the motor. Because of this, the cooling fan that was incorporated into the conventional 60 W min. products is no longer included.

No Dust, etc.

With no cooling fan, dust is not blown around.

Gearhead Features

Increased Deceleration and Torque When Combined With Gearheads

By combining the motor and gearhead, it is possible to reduce the speed to the desired speed or increase the torque.

Wide Variation

Different gearheads can be used for different applications.

Three-Phase High Efficiency Motor Optimal for Inverter Drive

Can be Combined With Other Manufacturers' Inverters

The three-phase high efficiency motor KIIS Series can be used in combination with inverters made by other manufacturers used by the customer. Easily control speed by combining with your existing inverter.

KIIS Series

Motor Performance Comparison

Rotation Speed and Speed Control Range

Standard AC motors (constant speed motors) such as induction motors, vary their rotation speed according to the power supply frequency, and the rated speed is approximately 1200 r/min at a frequency of 50 Hz and approximately 1450 r/min at 60 Hz. Speed control motors are available for a wide range of operating speeds from low to high.

Stopping Accuracy

When the motor is stopped, an overrun (overshoot) occurs.

Overrun can be reduced when an electromagnetic brake motor or instantaneous stop function are used.

Applications

-

Conveyor: Variable Speed

Can be Operated at a Set Speed When Combined With an Inverter

-

Turntable

Continues to Rotate at a Constant Speed

Narrow down Products