Introducing the Optimal Motor for Adjusting Torque Control and Tension

Introducing a Series of products suitable for "pushing and tightening," "tension adjustment," and "winding."

Recommended for those who are looking for a motor with adjustable torque and tension.

Typical Application Examples and Recommended Motors

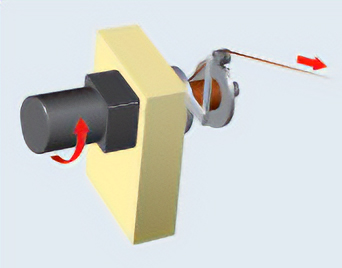

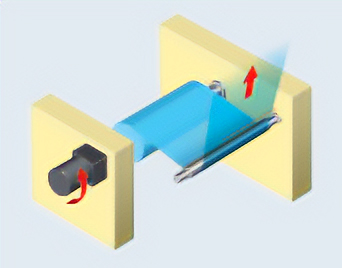

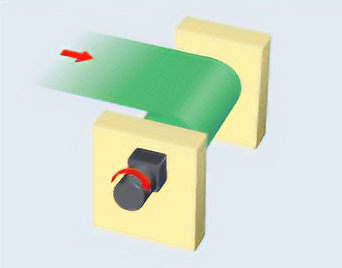

[Pushing and Tightening] Limits the Generated Torque, Preventing Damage to the Load

Typical Application Examples

-

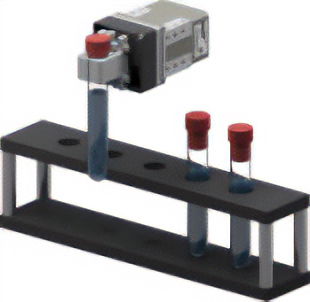

Gripper

-

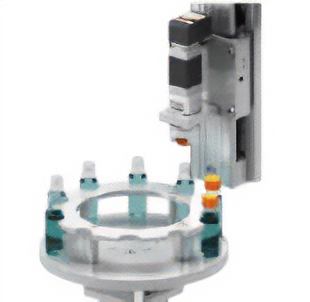

Capper (Filling unit)

-

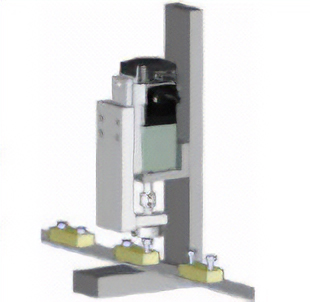

Press fit equipment

-

Alignment of Load

Recommended Motors

[Torque Motor]

Setting the torque value directly, prevents damage caused by over-tightening.

A simple system configuration can be built for a reasonable price.

[Brushless Motor/αSTEP/Servo Motor]

Setting the torque limiting value (torque limit), prevents damage due to over-tightening.

Since the signal is output when the set torque limiting value is reached, it can be used as a trigger for the next operation.

In addition, the αSTEP AZ Series is compatible with a variety of industrial networks, including EtherNet/IP.

| Product Category | Power Supply Input | Series | Output | Analog | Digital | ||

|---|---|---|---|---|---|---|---|

| Industrial Network | |||||||

| Torque Motors | AC | TM | 3~40 W* | ● | - | - | |

| Brushless Motors | AC | BLE2 | 30~400 W | ● | ● | - | |

| DC | BLH | Digital setting type | 15~50 W | ● | ● | - | |

| RS-485 Communication Type | 15~50 W | ● | ● | ● | |||

| BLV | 100~400 W | ● | ● | ● | |||

| αSTEP | AC/DC |

AZ (Including AZ Series equipped actuators) |

- | - | ● | ● | |

| Servo Motor | AC | NX | 50~750 W | ● | ● | - | |

Related Links

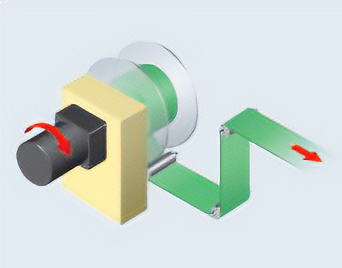

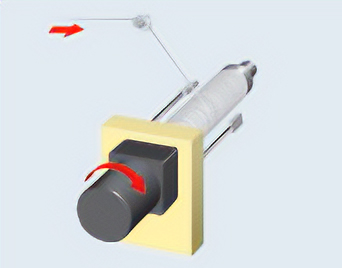

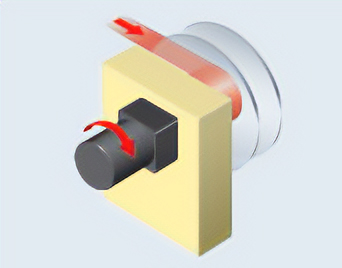

[Tension (tension adjustment)] Prevents Over-Tensioning and Sagging of the Material

Typical Application Examples

-

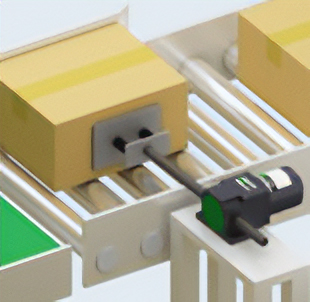

Sheet tension adjustment

-

Packaging tension adjustment

-

Lead wire tension adjustment

-

Film tension adjustment

Recommended Motors

[Torque Motor]

Motors can generate a braking force (reverse-phase brake) when rotated in the opposite direction to the motor rotation direction by an external force, etc. By using a torque motor on the unwinding side of the load, winding can be achieved while maintaining the appropriate tension. Also, since they do not wear out, there is no need for brake maintenance.

[Brushless Motor/Servo Motor]

This can be used as a brake to adjust the tension by limiting the generated torque, and rotating the motor in the opposite direction of the winding side. If the load is too heavy, it can also be used by rotating it in the same direction as the feed direction to assist in starting.

| Product Category | Power Supply Input | Series | Output | Analog | Digital |

|---|---|---|---|---|---|

| Torque Motors | AC | TM | 3~40 W* | ● | - |

| Brushless Motors | AC | BLE2 | 30~400 W | ● | ● |

| Servo Motor | AC | NX | 50~750 W | ● | ● |

- For continuous regeneration operation, use a regeneration resistor (sold separately)

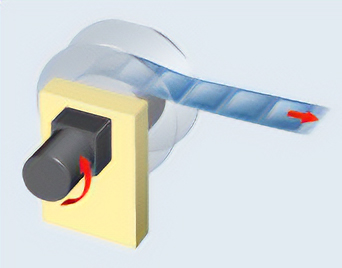

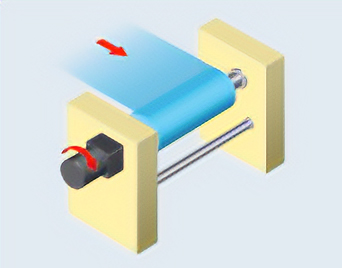

[Winding] Winding at constant tension and constant speed possible

Typical Application Examples

-

Sheet winding

-

Fiber winding

-

Tape winding

-

Film winding

Recommended Motors

[Torque Motor]

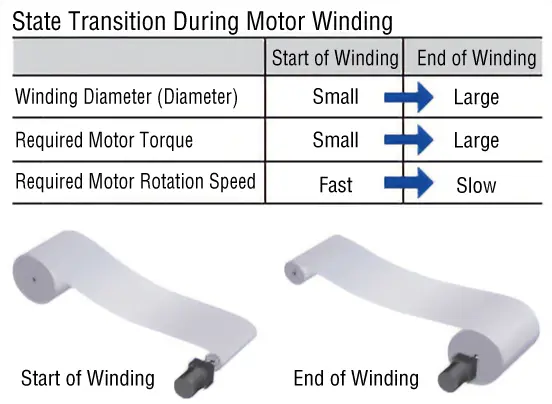

The torque and speed required of the motor changes as the winding diameter changes, as shown in the table below.

Torque motors have suitable characteristics for this change (sloping characteristics), making them ideal for winding applications.

[Servo Motor NX Series]

The tension control mode, in which the material thickness, initial diameter, and final diameter are set as parameters, allows highly accurate winding to be performed without the use of detectors or control devices.

| Product Category | Power Supply Input | Series | Output | Analog | Digital |

|---|---|---|---|---|---|

| Torque Motors | AC | TM | 3~40 W* | ● | - |

| Servo Motor | AC | NX | 50~750 W | ● | ● |

Compatible Products

| Product Category | Series | Power Supply Input | Pushing and tightening | tension | Winding |

|---|---|---|---|---|---|

| Torque Motors | TM | AC | ● | ● | ● |

| Servo Motor | NX | AC | ● | ● | ● |

| Brushless Motors | BLE2 | AC | ● | ● | - |

| BLH * | DC | ● | - | - | |

| BLV | DC | ● | - | - | |

| αSTEP | AZ | AC/DC | ● | - | - |

- *Digital setting type and RS-485 communication type only

"Electric Actuator" That Can Push and Tighten

| Actuator Types | Series | Power Supply Input | Maximum Stroke [mm] | Maximum Push Force [N] |

|---|---|---|---|---|

| Electric Gripper | EH | DC | 25 | 25 |

| Compact Electric Cylinder | DR | DC | 30 | 50 |

| DRS2 | DC | 50 | 500 | |

| Electric Cylinder | EAC | AC/DC | 300 | 500 |

| Electric Linear Slide | EAS | AC/DC | 500 | 200 |

| EZS | AC/DC | 850 | 500 | |

| EZSH | AC | 1300 | 325 | |

| Rack-and-Pinion System | L | AC/DC | 1000 | 1008 |

Push force and push current value (Reference value)

Request Motor Sizing

Motor sizing such as torque computation is performed on the customer's behalf. (Free of charge)

Opening Hours: 8:00 am to 4:30 pm (except for public holidays and company holidays)