Brushless Motors

BLV Series R Type

- Compact Driver Compatible with Battery Drive

- Compact and High Power, Ideal for Guided Vehicles

- Compatible with Modbus and CANopen Communication

- Output Power 60 to 400 W

- Speed Control Range 1 to 4000 r/min

Features | Brushless Motor BLV Series R Type

- Overview and Applications

- Compact, Lightweight, and High Power

- Wide Speed Control Range, High Speed Stability

- Improved Usability / Recommended Functions

- Communication Control Possible

- Gearheads and Wheel Mechanisms Can Be Selected According to the Application

- Acquisition of STO Certification

- Support Software Compatible

Overview and Applications

2-Minutes Explanation of the BLV Series R Type

See the features of the BLV Series R Type in this video.

- Output Power: 60 W, 100 W, 200 W, 400 W

- Compact and Lightweight Drivers

- Power Supply Input: 24~48 VDC

- Also Available With Electromagnetic Brake

Applications

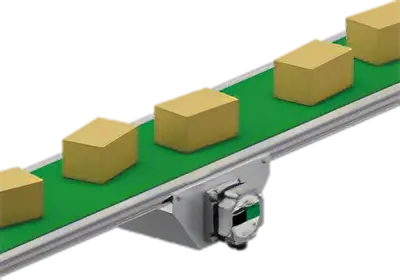

Autonomous Mobile Robot With Belt Conveyor

Low Floor Transportation Robot

Agitator

Conveyor

Motorized Heads for Security Cameras

Compact, Lightweight, and High Power

Compact and Lightweight Design

Both the motor and the driver are significantly smaller and lighter.

Motor*

- *Parallel Shaft Gearhead 400 W, Gear Ratio: 30

Driver

- For the 24 VDC 400 W type, 160 (W) mm x 110 (D) mm x 35 (H) mm and 0.46 kg mass.

High Power

Capable of driving larger load inertia than conventional products, enabling the transport of heavy loads.

[Transportation Robot Equipment Design Example]

Conditions

| BLV Series R Type Motor |

Type | Parallel Shaft Gearhead |

|---|---|---|

| Output Power | 400 W | |

| Gear Ratio | 30 | |

| Driving Condition | Wheel Diameter | 150 mm |

| Number of Drive Wheels | 2 | |

| Acceleration Time | 1 sec. |

Result

| Maximum Transportable Mass (Transport robot body mass + load mass) |

500 kg |

|---|---|

| Maximum Travel Speed | 0.7 m/sec |

- *Calculated using a wheel friction coefficient of 0.1.

![[Transportation Robot Equipment Design Example]](/sites/default/files/image/products/brushless-motors/blv-r/blv-r_08.webp)

Wide Speed Control Range, High Speed Stability

Wide Speed Control Range: 1~4000 r/min

Low speed range from 1 r/min provides stable operation for smoother starts and stops.

Advantages

- Achieves smooth operation even with repeated starts and stops such as when following the motion of a person.

High Speed Stability Ensures Operation at the Speed Set

Speed regulation (load) is as small as ±0.01 %. Operation maintains the set speed even if load magnitude changes.

- *±0.2 % at digital setting

Present Position Acquisition and Positioning Operation Available

Since the motor provides abundant feedback information, the present position can be acquired.

In addition, stops can be set to your desired position through the improved resolution.

- Stopping accuracy during positioning operation is ±0.72° on the motor shaft and 1~2° on the gearhead output shaft.

Improved Usability/Recommended Functions

Expanded Allowable Operating Voltage

Advantages

- 24~48 VDC batteries are compatible.

- Does not stop even when battery voltage deteriorates.

Continuous operation while limiting rotation speed and torque.

Power Consumption Reduced by 10 %

Advantages

- For battery-powered transportation robots, the distance and travel time capabilities are extended.

As a result, batteries can be charged less frequently. - The MEXE02 support software can monitor the power consumption remotely.

This can be used as a guideline for recharging.

Electric Brake Enables Hold During Stops

Holding force is generated in a stopping motor that is excited (servo-on).

Even motors without an electromagnetic brake can be used as an electric holding brake.

There is also a function to hold position so that it does not deviate from the stopping position.

ATL Function Automatically Limits Output Torque

Even if the motor is overloaded, the ATL function attempts to continue operation by reducing the output torque to prevent the motor from stopping due to the overload alarm.

Simplifying the Main Program via Sequence Function

When used during a stored data operation, it comes equipped for a wide variety of sequence functions, such as including linked operation, timer settings for each operation, conditional branches, and loop count.

- Number of stored data settings (up to 256 points)

- Direct I/O signal counts (input 4, output 2)

- Remote I/O signal counts (input 32, output 32)

Communication control possible

BLV Series R Type is compatible with 2 communication interfaces: Modbus (RTU) and CANopen.

Main Functions Available in Modbus (RTU)

Free Creation of Operation Profiles: Direct data operation

This is an operation method that can simultaneously rewrite data and initiate operations with Modbus (RTU) communication.

| Operation Data Type | Description |

|---|---|

| Operation Mode | Sets the operation mode. |

| Position | Sets the target position. |

| Speed | Sets the operating speed. |

| Acceleration Rate | Sets the acceleration time. |

| Deceleration Rate | Sets the deceleration time. |

| Torque Limiting Value | Sets the torque limiting value. |

Jointly Sending and Receiving Different Data With Each Axis: ID share mode

This function improves synchronization between axes through Modbus (RTU) communication.

Communication delay between axes is improved because data can be sent and received jointly through multiple axes.

It is also possible to send different commands to each axis at the same time.

This is our proprietary transmission method.

Gearheads and Wheel Mechanisms Can Be Selected According to the Application

Various Gearheads and Driving Wheel Motors

The lineup includes driving wheel motor that integrate the motor, hollow shaft flat gearhead, and wheel mounting shaft. It contributes to time saving in axle mechanism design and wheel selection for AGV, AMR, and other transport robots.

| Gearhead Type | Parallel shaft gearhead | Hollow shaft flat gearhead | Wheel Mechanism: Driving Wheel Motor | ||||

|---|---|---|---|---|---|---|---|

| GFV Gearhead | CS Geared Motor | FR Gearhead | |||||

| External View |

|

|

|

|

+ |

|

|

| Features |

|

|

|

|

|||

| Motor Output Power | 60 W, 100 W, 200 W, 400 W | 60 W | 60 W, 100 W, 200 W, 400 W | 100 W, 200 W, 400 W | |||

| Gear Ratio | 5~200 | 5~20 | 5~200 | 20, 50 | |||

- *

- Load capacity is the value added per wheel. Be sure to install passive wheels to prevent exceeding the load capacity.

Acquisition of STO Certification

Obtaining STO* certification has made it easier to support safety systems. It reduces the number of peripheral devices, and achieves cost reduction and space saving.

- *STO (Safe Torque Off) function equipped

SIL 2, PL d Functional Safety Certification Obtained

| Applicable Standards | Safety Level |

|---|---|

| IEC 61800-5-2, EN 61800-5-2 | SIL 2 |

| IEC 61508-1, EN 61508-1 | |

| IEC 61508-2, EN 61508-2 | |

| ISO 13849-1, EN ISO 13849-1 | PL d (Category 3) |

Advantages of Certified Products and Examples of Applications

Applicable Products

Brushless Motor BLV Series R Type Driver

Certificates can be downloaded from product details page. (User registration required for downloads.)

For downloading instructions, refer to frequently asked questions about downloading data.

Support Software Compatible

The MEXE02 support software allows data setting, real drive operations and other various types of monitors to be done via a PC.

Support software can be downloaded from the Oriental Motor website free of charge.

Start-Up A Function for Smooth Equipment Start-up

Simple Settings

"Simple communication settings" can be used to set up each communication type easily.

Operation Functions to help with adjustments

Waveform Monitor

The operating status of the motor (command speed, torque, I/O signals, etc.) can be monitored like an oscilloscope.

Waveform readings can be saved as images or in CSV file format.

FFT Monitor

Mechanical resonances visualization is achieved through frequency analytics using FFT analysis. Sound and vibration can be reduced by adjusting the "resonance suppression parameters."

Maintenance Useful functions for diagnosis and maintenance

Trace Monitor

The operation status of the motor can be continuously monitored for over 24 hours.

Data can be saved in CSV format.

Advantages

- Since data is retained over a long time period, determining the cause of problems is easier.

Various Monitoring Functions

MEXE02 support software can also be used for monitoring a variety of other information.

Refer to the page below for details.

Click here for information about all the functions of the MEXE02 support software

Related Products

Brushless Motors

BLH Series

- 24 VDC input, compact driver

- Ideal for incorporating in equipment

- RS-485 communication compatible

- 15~100 W, (80) 100~3000 r/min

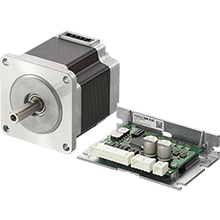

Stepper Motors

PKP Series/CVD Series SC Type Driver

- Easy control with forward/reverse input

- 2-speed operation

- 0.02~600 r/min

Narrow down Products