Loader/Unloader (Lifting Equipment) Case Study of Bucket Transfer Automation

Issue

Automating the Loading and Transportation of Buckets

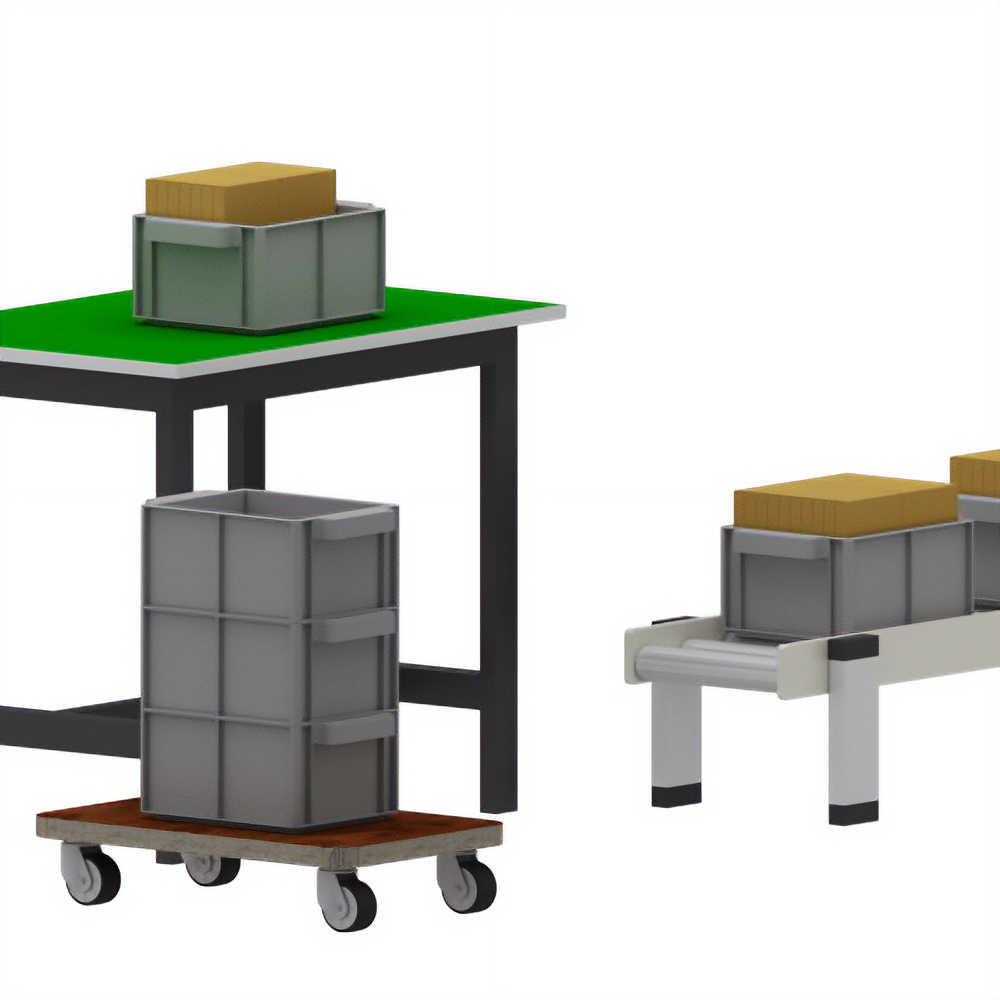

Conventional Equipment

The process of manually loading retort food into buckets and transporting them to the inspection process.

- Application

- Bucket Transfer

Conventional Problem

- Since the loading and unloading of the buckets was done manually, the production volume was inconsistent

Solution

L Series

AC Speed Control Motor DSC Series Equipped

Rack-and-Pinion Mechanism Automates Transfer

The L Series of Rack-and-Pinion Systems can be used to automate the lifting and lowering of empty buckets and their transportation to the next process. Since it does not rely on manpower, it is easier to estimate production volume.

Specific Application Examples

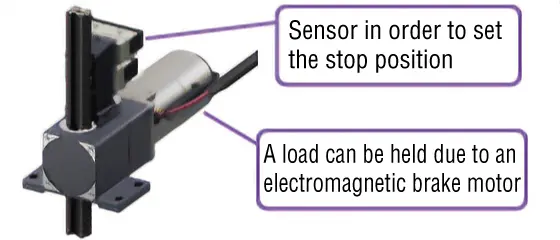

Rack-And-Pinion System Reduces Manpower

Since the rack-and-pinion mechanism and motor are integrated, once the motor is activated, all subsequent lifting and lowering can be automated. The stop position can be set by mounting the sensor.

The motor has a built-in load holding electromagnetic brake, so there is no need to worry about the bucket falling when it stops.

Reduce Takt Time by Switching Speed According to the Situation

The DSC Series-Equipped L Series allows the setting of 4 different operation data (speed, etc.).

The takt time of the entire process can be reduced by using different operation data, such as low speed to raise the bucket with a load, and high speed to lower it after feeding.

Digitally setting the operating speed pattern in advance makes it easier to estimate the production volume.