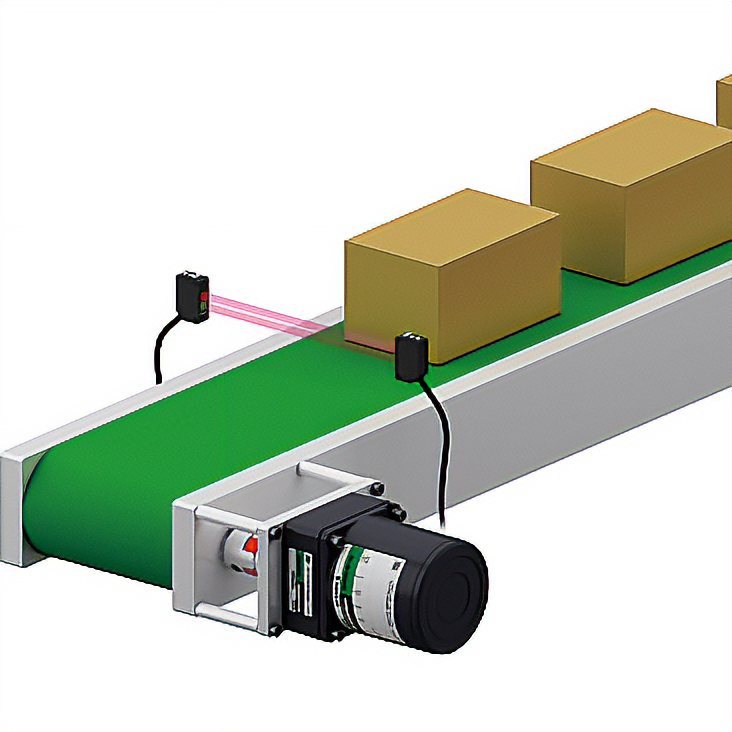

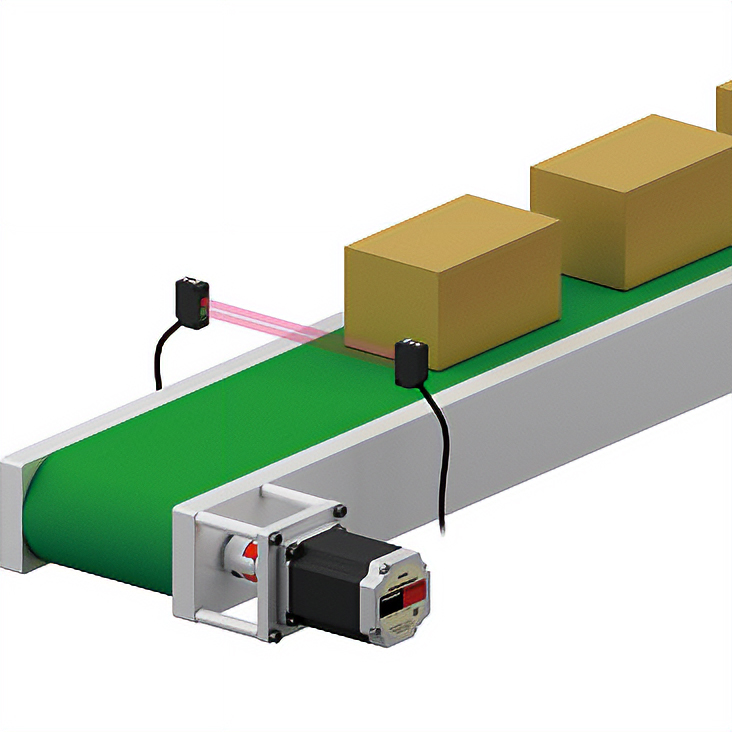

Case Study of Improvement of Positioning Accuracy on a Belt Conveyor Using a Stop Sensor

Problem

Improving the Accuracy of the Stop Position

Conventional Equipment

A three-phase induction motor drives the conveyor and an external sensor input stops the conveyor (an inverter is used for speed control)

- Application

- Transporting loads

Conventional Problems

- Stopping position varies with changes in workpiece weight and operating speed

(Induction motor overrun amount changes)

Solution

Stepper Motor PKP Series/CVD Series SC-Type

Improved Stopping Accuracy with Simple Control

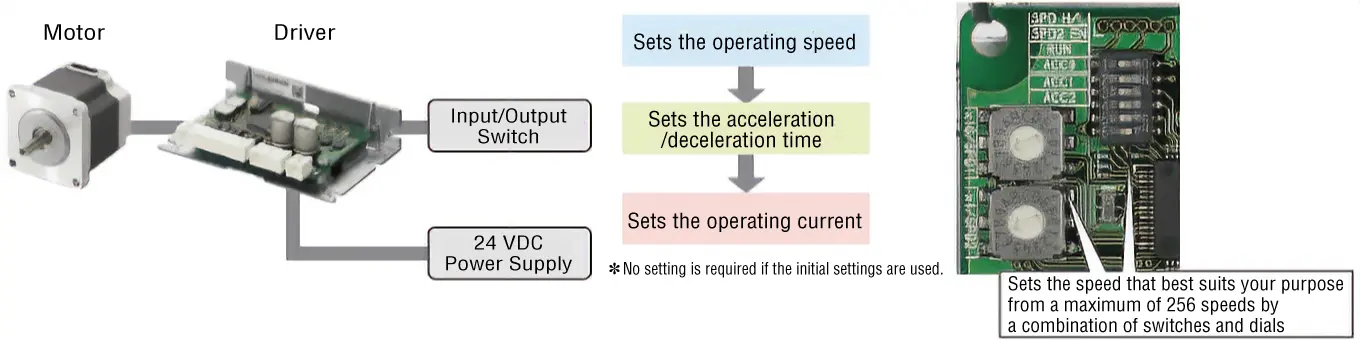

The PKP Series/CVD Series SC Type features improved stop position repeatability thanks to constant travel amounts from the sensor input.

Specific Application Examples

Improved Stop Position Repeatability

The stop position will not change if the operation conditions are the same, even when using an external sensor to stop the motor. No variation occurs, even when the load weight changes.

This improves stop position repeatability.

A self-holding force is generated in the energized state to maintain the stop position.

A Simple System Configuration for Easy Control

Simply setting the operating speed in the driver and input operation commands makes driving easy. No pulse generators are required.

Reduction of Motor Size and Weight

Compared to induction motors, motors can undergo downsizing, which contributes to smaller and lighter equipment.