Installation Conditions and Degree of Protection Relating to Protection against Electric Shock

1. Overvoltage Category

In accordance with EN 60664-1 (Insulation coordination for equipment within low-voltage supply systems - Part 1: Principles, requirements and tests), the degree of transient overvoltage that occurs at the power receiving point directly connected to the equipment is classified as follows.

- Overvoltage Category I:

- Equipment to be connected to circuits where transient overvoltage is reliably limited to a sufficiently low level, such as a stabilized power supply. (Our DC input products fall under this category.)

- Overvoltage Category II:

- Equipment to be connected to circuits where transient overvoltage is unlikely to occur, such as secondary circuits via isolated transformers. (The majority of our AC input products fall into this category.)

- Overvoltage Category III:

- Equipment to be connected to circuits where transient overvoltage is expected to occur, such as the power supply from a distribution panel in a general factory that does not go through an isolated transformer. (Some of our AC input products fall under this category.)

2. Pollution Degree

The degree of environment in which the equipment is used is indicated in accordance with EN 60664-1 (Insulation coordination for equipment within low-voltage supply systems - Part 1: Principles, requirements and tests).

- Pollution Degree 1:

- Completely free of material contaminants, always dry, and no possible effect on equipment due to contamination (e.g.. cleanroom, etc.).

- Pollution Degree 2:

- There are conductive materials that result in some pollution, and these are thought to have an effect at times on the device (offices, research laboratories).

- Pollution Degree 3:

- Conductive materials that can become contaminants, and these are thought to have an effect on the equipment (boiler room, general factory).

However, even in equipment used in a pollution degree 2 environment, if the structure of the equipment causes contamination inside, the equipment must be designed to accommodate a lower pollution degree.

3. Electric Shock Protection Class

Methods of protection against electric shock by equipment are divided into the following protection classes by EN 61140 (Protection against Electric Shock - Common Aspects for Installation and Equipment). (Protection Class)

- Class I Equipment

- Equipment in which protection against electric shock is achieved through basic insulation and equipment that provides a means of connecting to the protective earth conductor in the building wiring of those conductive parts that are otherwise capable of assuming hazardous voltages if the basic insulation fails.

- Class II Equipment

- Equipment in which protection against electric shock does not rely on basic insulation only, but, in which safety measures, such as supplementary insulation or reinforced insulation are provided without reliance on protective earth.

- Class III Equipment

- Equipment in which protection against electric shock relies upon power supply from SELV circuits and in which hazardous voltages are not generated.

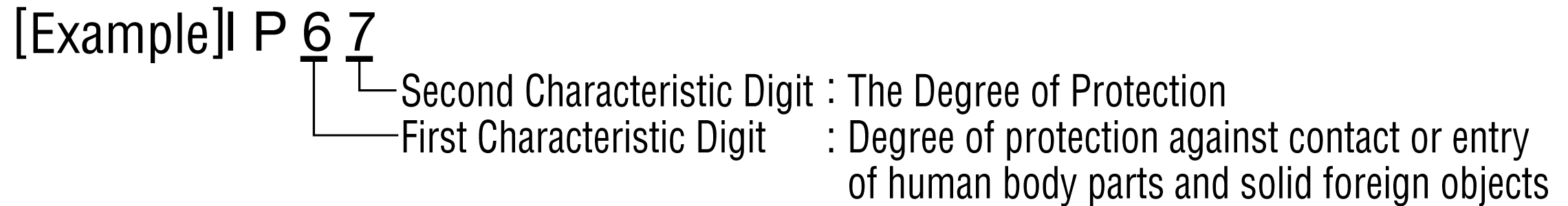

4. Degree of Protection (IP)

This represents the degree of protection against human contact with hazardous parts of electrical equipment, against intrusion of solid object into the equipment, and against ingress of water. The degree of protection for common electrical equipment is specified by EN 60529 as an IP code. The degree of protection for motors, which are electrical equipment with rotating parts, is specified in EN 60034-5.

Furthermore, when one of the two protection degrees is not specified in the name, the code X is used to represent it (e.g., IPX5, IP4X).

| IP Code | Protection against human contact with hazardous parts, protection against solid objects entering the interior | |

|---|---|---|

| First Characteristic Numeral | Protection Level | Test Condition |

| IP0X | None | None |

| IP1X | Protection against approach by hands | Solid objects with a diameter of 50 mm or more do not enter |

| IP2X | Protection against approach by fingers | Solid objects with a diameter of 12 mm or more do not enter |

| IP3X | Protection against tips of tools, etc. | Solid objects with a diameter of 2.5 mm or more do not enter |

| IP4X | Protection against ingress of wires, etc. | Solid objects with a diameter of 1.0 mm or more do not enter |

| IP5X | Protection against powdery dust | Powdery dust that may inhibit normal operation does not enter |

| IP6X | Completely dust-proof structure | Cannot be penetrated by powdery dust |

| IP Code | Degree of Protection Against Water Ingress | |

|---|---|---|

| Second Characteristic Numeral | Protection Level | Test Condition |

| IPX0 | None | None |

| IPX1 | Protection against water drops falling vertically | Water drops at a rate of 3 to 5 mm/min for 10 minutes from a height of 200 mm |

| IPX2 | Protection against water drops from directions within a range of 15˚ relative to the vertical plane | Water drops at a rate of 3 to 5 mm/min for 10 minutes from directions within 15˚ from a height of 200 mm |

| IPX3 | Protection against raindrops from directions within a range of 60˚ relative to the vertical plane | Sprayed water at a rate of 10 ℓ/min for 10 minutes from directions within 60˚ from a height of 200 mm |

| IPX4 | Protection against ingress of splashes from all directions | Sprayed water at a rate of 10 ℓ/min for 10 minutes from all directions at a distance of 300~500 mm |

| IPX5 | Protection against water jet from all directions | Sprayed water jet of 30 kPa at a rate of 12.5 L/min for 3 minutes from all directions at a distance of 3 m |

| IPX6 | Protection from waves or powerful jet streams | Sprayed water jet of 100 kPa at a rate of 100 L/min for 3 minutes from all directions at a distance of 3 m |

| IPX7 | Usable after immersion in water under specified conditions | Immersion to a depth of 1 m for 30 minutes |

| IPX8 | Usable under water | Determined through cooperation between user and manufacturer |