αSTEP Battery-Free Built-In Absolute Encoder AZ Series

AZD-CEP

Control Circuit

| Product Classification | Product Name | List Price | Shipping Date |

|---|---|---|---|

| Control Circuit | AZD-CEP | €618.00 | Up to 20 pcs Estimated Ship 4weeks |

Included

- Control Circuit: Main Power Supply/Regeneration Resistor Connector (CN4), Connector for 24 VDC Power Supply input·Electromagnetic Brake Connector·Regeneration Unit Thermal Input·power removal signal input (CN1), I/O Signal Connector (CN7), Connector Wiring Lever

Specifications

Dimensions

Data Download

Other Specifications

Driver Specifications

| Driver Product Name | AZD-AD, AZD-CD | AZD-AM3, AZD-CM3 AZD-AS3, AZD-CS3 |

AZD-AEP, AZD-CEP AZD-AED, AZD-CED AZD-APN, AZD-CPN AZD-AX, AZD-CX AZD-A, AZD-C |

|

|---|---|---|---|---|

| Interface |

Pulse Input | - | - |

|

| Control Input | 10 Points Photocoupler |

4 Points Photocoupler |

6 Points Photocoupler |

|

| Pulse output | 2 Points Line Driver |

- | 2 Points Line Driver |

|

| Control output | 6 Points Photocoupler and Open-Collector |

3 Points Photocoupler and Open-Collector |

6 Points Photocoupler and Open-Collector |

|

| Power Shut Down Input Signals |

2 Points Photocoupler |

|||

| Power Shut Down Monitor Output |

1 Point Photocoupler and Open-Collector |

|||

Driver function

| Built-In Controller Type | Pulse Input Type with RS-485 Communication | Pulse Input Type |

EtherNet/IP Compatible PROFINET Compatible |

||||

|---|---|---|---|---|---|---|---|

| Number of Positioning Data Sets | 256 Points | 256 Points*1 | 256 Points | ||||

| Remote I/O | Input | 16 Points | - | 16 Points | |||

| Output | 16 Points | - | 16 Points | ||||

| Setting Tool | Support Software MEXE02 | ||||||

| Coordinates Management Method | Battery-free Absolute System | ||||||

| Operation | Positioning Operation | Product Line | Positioning Operation | ○ | ○ | ○*1 | ○ |

| Positioning Push-Motion Operation*2 |

○ | ○ | ○*1 | ○ | |||

| Fastening method | Single-motion Operation | ○ | ○ | ○*1 | ○ | ||

| Sequential Operation | ○ | ○ | ○*1 | ○ | |||

| Multistep Speed-Change (Configuration connection) |

○ | ○ | ○*1 | ○ | |||

| Sequence control | Loop Operation (Repeating) |

○ | ○ | ○*1 | ○ | ||

| Event Jump Operation | ○ | ○ | ○*1 | ○ | |||

| Speed Control Operation (Continuous operation) | ○ | ○ | ○*1 | ○ | |||

| Return-To-Home Operation | Return-To-Home Operation | ○ | ○ | ○ | ○ | ||

| High-speed return-to-home operation | ○ | ○ | ○ | ○ | |||

| JOG Operation | ○ | ○ | ○ | ○ | |||

| Monitor/Information | Waveform Monitoring | ○ | ○ | ○ | ○ | ||

| Overload Detection | ○ | ○ | ○ | ○ | |||

| Overheat Detection (Motor and Driver) |

○ | ○ | ○ | ○ | |||

| Position/Speed Information | ○ | ○ | ○ | ○ | |||

| Temperature Detection (Motor and Driver) |

○ | ○ | ○ | ○ | |||

| Motor Load Factor | ○ | ○ | ○ | ○ | |||

| Travel Distance , Cumulative Travel Distance | ○ | ○ | ○ | ○ | |||

| Alarm | ○ | ○ | ○ | ○ | |||

- *1

- It can be used by setting it with the MEXE02 support software.

- *2

- Push-motion operation is not available for the geared motor and electric actuator DGII Series.

Communication Specifications

| Communication Protocol | EtherNet/IP (CT16 compliant) | |

|---|---|---|

| Vendor ID | 187: Oriental Motor Company | |

| Device Type | 43: Generic Device | |

| Transmission Rate | 10/100 Mbps (autonegotiation) | |

| Mode | Full duplex/half duplex (autonegotiation) | |

| Cable Specification | Shielded twisted pair (STP) cable Straight/cross, category 5e or higher |

|

| Number of Occupied Bytes | Output (Scanner → Driver) | 40 bytes |

| Input (Driver → Scanner) | 56 bytes | |

| Implicit Communication | Number of Connections Supported | 2 |

| Connection Type | Exclusive owner, input only | |

| Communication Cycle (RPI) | 1~3200 ms | |

| Connection Type (Scanner → Driver) | Point−to−Point | |

| Connection Type (Driver → Scanner) | Point−to−point, multicast | |

| Data Trigger | Cyclic | |

| IP Address Setting Method | IP address setting switches, parameters, DHCP | |

| Supported Topologies | Star, linear, ring (device level ring) | |

Driver General Specifications

| Item | Specifications | |

|---|---|---|

| Operating Environment (In operation) | Ambient Temperature | 0 to +55 °C (Non-freezing)* |

| Ambient Humidity | 85 % max. (Non-condensing) | |

| Atmosphere | No corrosive gases or dust. No exposure to water, oil or other liquids. | |

- *When installing a heat sink equivalent to an aluminum plate min. 200 × 200 mm, thickness 2 mm

Standards

Regulations and Standards Materials

Documents about compliance with regulations and standards can be downloaded from the "Data Download" tab on the product details page.

(The types of files available for download vary by product.)

Explanations of the Global Laws, Regulations and Standards can be found here.

Information about our compliance with regulations and standards for each of our product series can be found here.

Hazardous Substances

The product does not contain any substances (10 substances) exceeding the regulation values of the RoHS Directive (2011/65/EU, 2015/863/EU).

For more information about compliance with regulations on chemical substances in Oriental Motor's Products, click here.

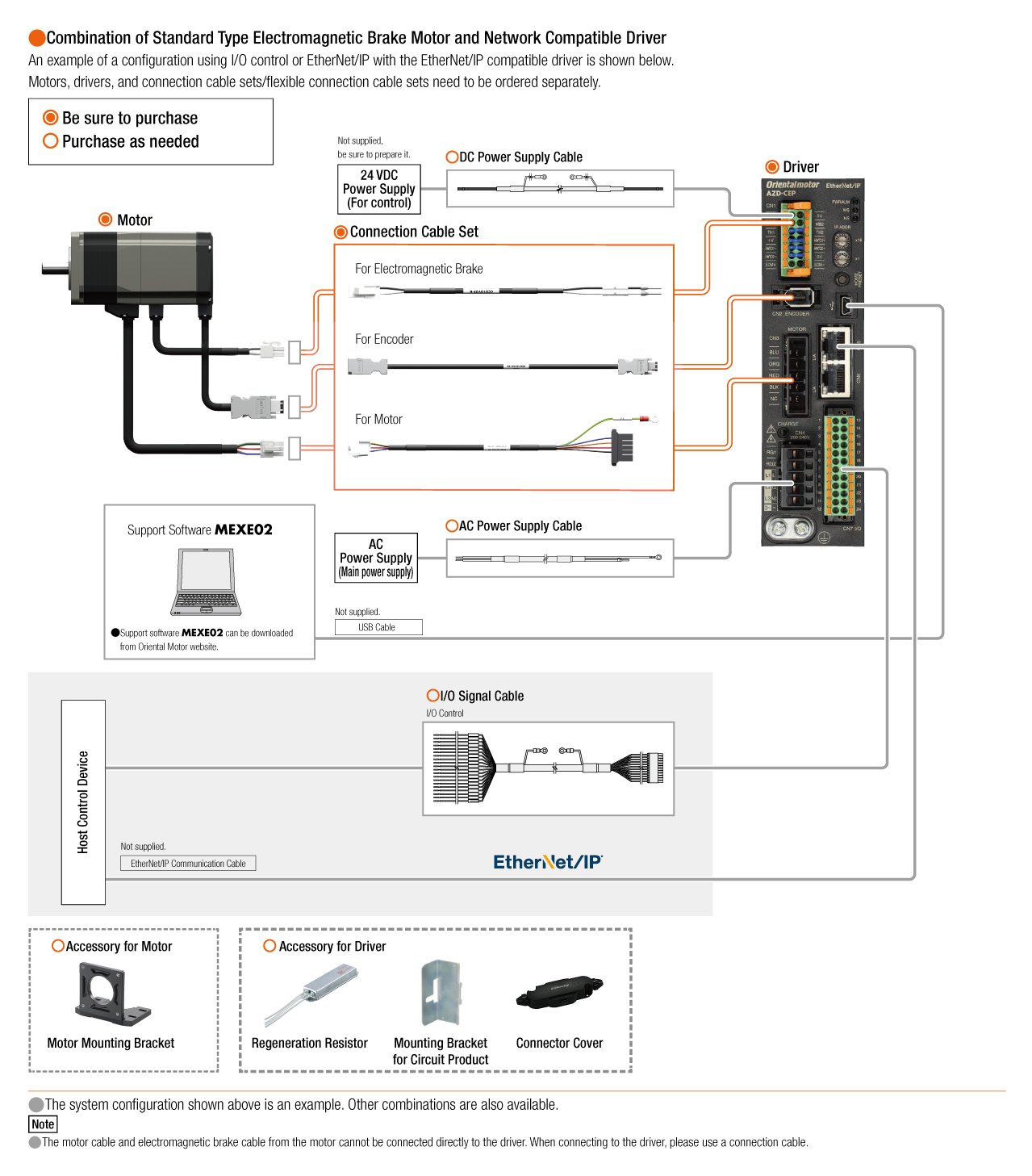

System Configuration

Cables and Accessories

close

close