Case Study on Compact Multi-Axis Driver Installation to Reduce the Footprint of Semiconductor Manufacturing Equipment

| Industries | Semiconductors, Displays, Electronic Components |

|---|---|

| Process and Equipment Name | Semiconductor Manufacturing Equipment (Inspection, Etching, Deposition, Bonding, etc.) |

| Issue | Space-saving, Reduction in Man-hours for Wiring |

Issue: To Achieve Both an Increase in the Number of Motor Axes and Downsizing of Equipment

Conventional Problems

- It is Necessary to Increase the Number of Motor Axes on the Equipment Due to Process Increase or Process Change, but This Leads to Increased Driver and Wiring Space As Well as Man-Hours for Wiring

- I Would Like to Downsize the Equipment As the Number of Equipment Installation Increases

Solution: Slim Type Multi-Axis Driver Save Space

In the manufacturing process of advanced semiconductors, the amount of equipment used tends to increase to accommodate miniaturization and multilayered structure. On the other hand, there is a limit to the equipment installation space, and in order to improve productivity in next-generation semiconductor manufacturing equipment, it is essential to achieve a reduction in the footprint of the equipment overall.

AZ Series multi-axis driver slim type can control four axes of motors with a single unit and can reduce space significantly compared to existing multi-axis drivers.

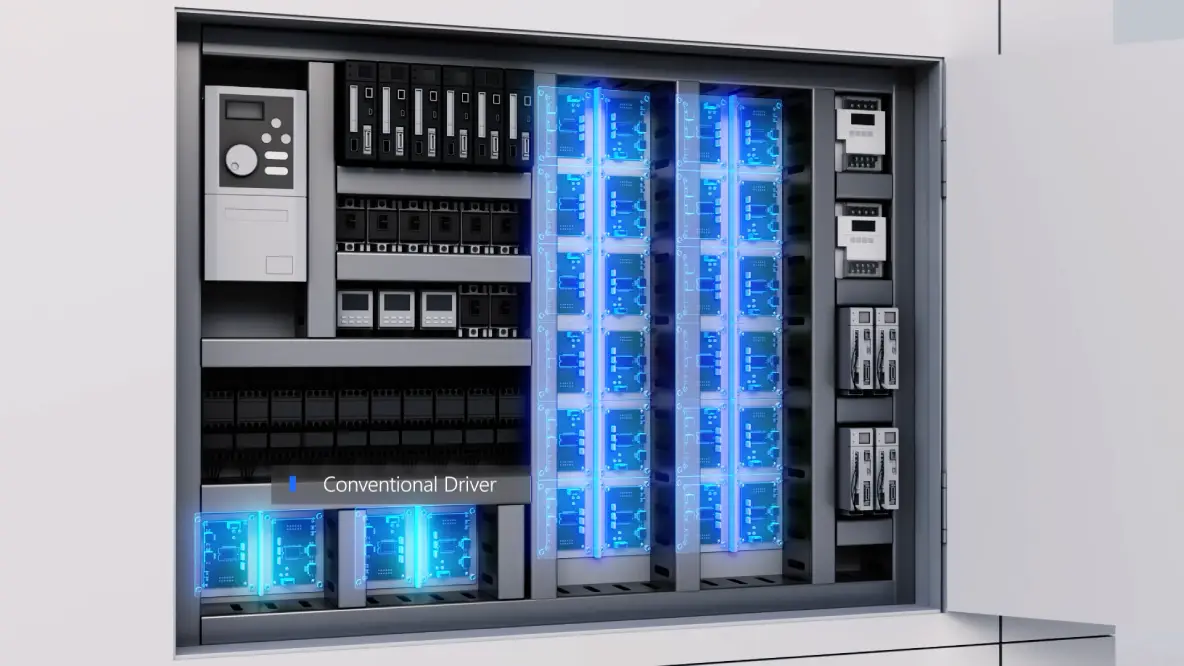

Compact Multi-Axis Driver With a Width of 60 mm Reduces Installation Space by about 66 % Compared to Conventional Models

Conventional single-axis drivers occupy a width of 180 mm for four units, and existing multi-axis drivers require a space of 147 mm for 4-axis drive support.

AZ Series multi-axis driver slim type supports 4-axis drive and has a width of 60 mm, which is about 66 % less space than a single-axis drive driver. The significant reduction of driver installation space contributes to the reduction in footprint, enabling the overall downsizing of equipment.

Image of Installation Space Reduction With AZ Series Multi-Axis Driver Slim Type

Network Compatible and Multi-Axis Driver Reduces Wiring

AZ Series multi-axis driver slim type has a lineup of products that support MECHATROLINK-III and SSCNETIII/H, respectively, in addition to EtherCAT. A single driver can control multiple axes, thus reducing wiring in the control cabinet.

Compatible With Motors With a Frame Size of 42 mm or Less

AZ Series multi-axis driver slim type can be connected to AZ Series DC input motors and electric actuators equipped with these motors. When using a motor with a frame size of 42 mm or less with multiple axes, please consider the slim type first.

Product Proposal: AZ Series Multi-Axis Driver Slim Type

EtherCAT, MECHATROLINK-III, and SSCNETIII/H compatible products are available.

Combinable Motors

AZ Series DC Input

Frame size □20 mm, □28 mm, □42 mm

Combinable Electric Actuators

- AZ Series Equipped Electric Linear Slide EZS Series DC Input

- AZ Series Equipped Electric Cylinder EAC Series DC Input

- AZ Series Equipped Compact Electric Cylinder DR Series/DRS2 Series

- AZ Series Equipped Hollow Rotary Actuator DGII Series DC Input