Sheet Winding Device (Feeder Section) Case Study of Prevention of Sheet Damage and Sagging by Automatic Adjustment Of Tension

Issue

Preventing Sagging and Damage to the Sheet (Feeding Section)

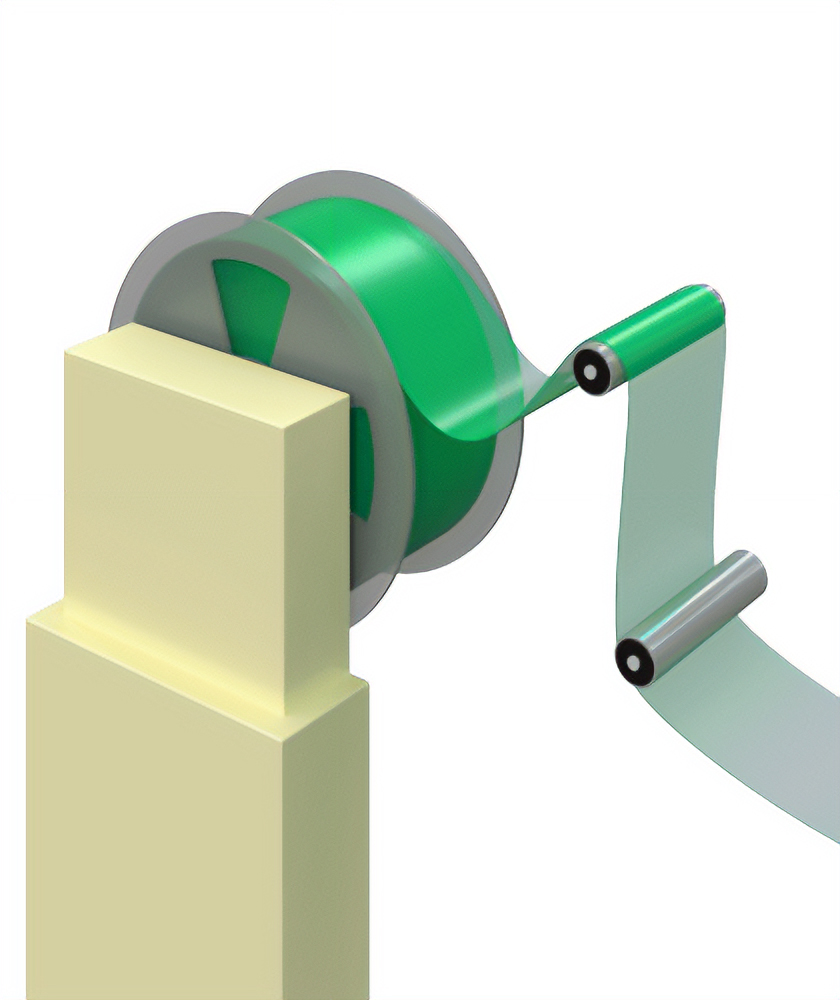

Conventional Equipment

Winding process for sheet manufacturing equipment using an induction motor.

A motor is used only for the winding section.

- Application

- Winding of packaging sheets, tapes, films, and paper rolls

Conventional Problems

- The increase in winding diameter causes changes in the load and winding speed, which resulted in sagging and damage to the sheet

- Wanting to install a tension controller and torque detector, but unable to do so due the high costs

Solution

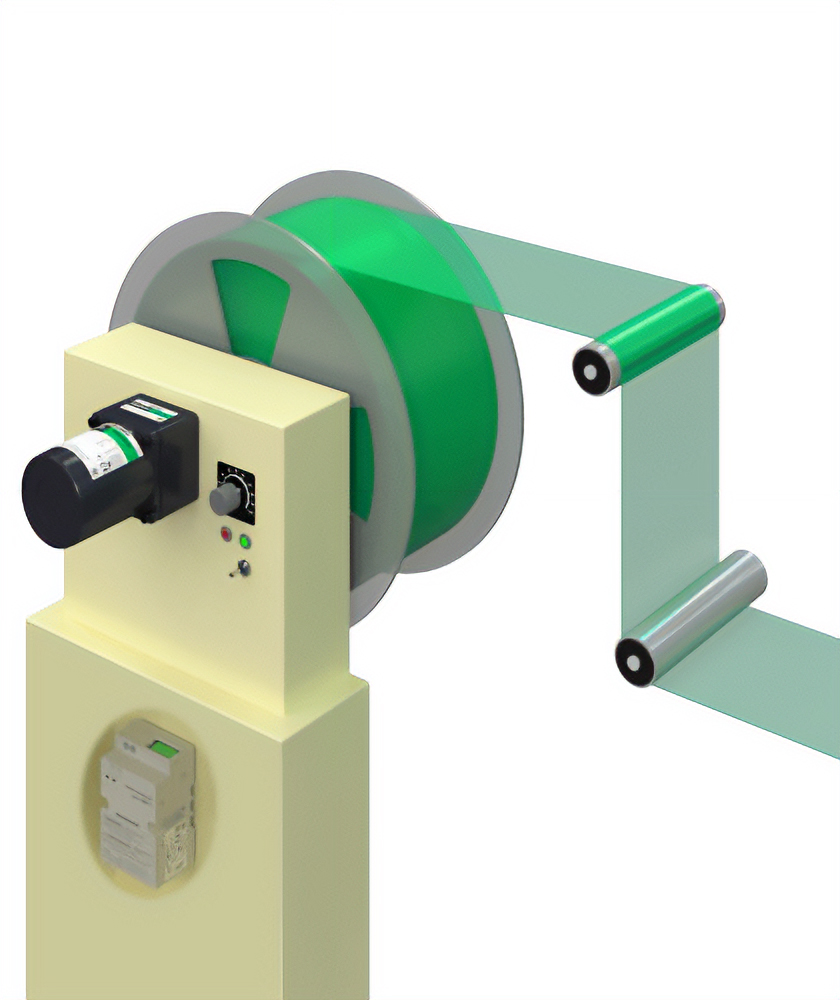

Torque Motor TM Series

Serves as a brake for feeding and unwinding

The TM Series, which is able to use motor power as a brake, can be installed on the sheet feeding and unwinding sides to maintain proper tension while winding.

Specific Application Examples

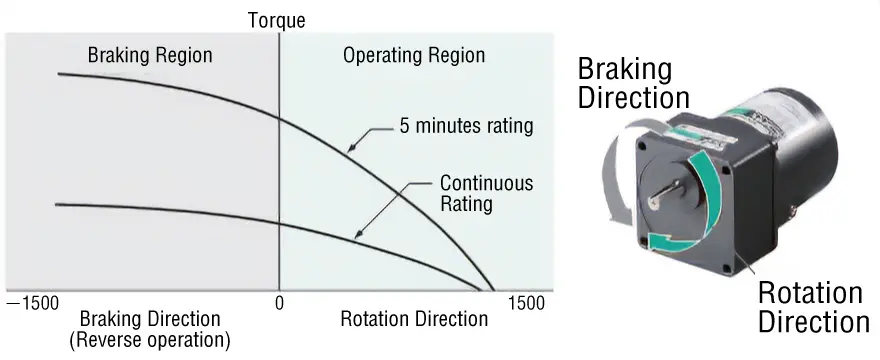

Torque Motors That Can be Used as Brakes

The TM Series can also generate a braking force when rotated in the opposite direction to the motor rotation direction by an external force, etc. If installed on the feeding or unwinding side, the brake characteristics can be used as tension.

Achieves Low-Cost System Configuration

The list price of the TM Series (Torque Motor and Power Controller) ranges from 19,300 JPY~34,400 JPY.

More cost-effective than using tension controllers and torque detectors.

Easy Torque Setting with Dedicated Power Controller

One of the components, the power controller, is used in torque setting.

3 setting methods can be selected: Internal Torque Potentiometer, External Torque Potentiometer, and DC Voltage Control.