Case Study of Weight Reduction of the Motor Section of a Grip Conveyor (Side Conveyor)

Issue

Reducing the Weight of the Motor Section

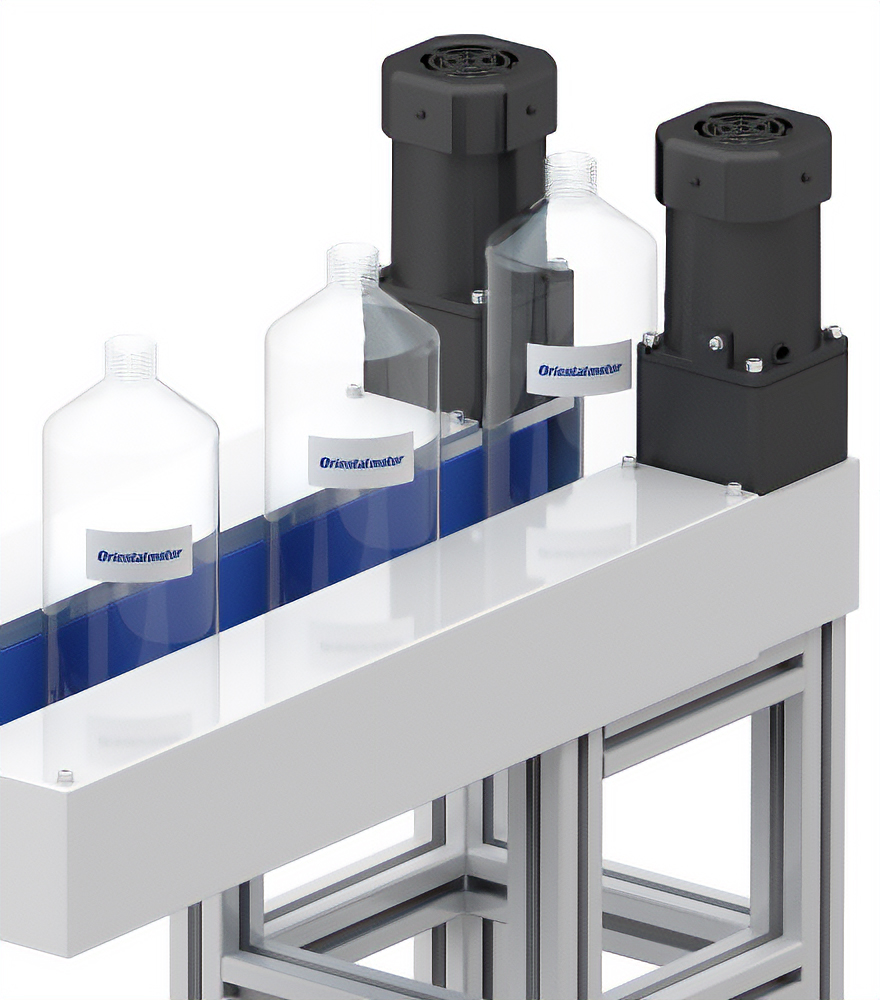

Conventional Equipment

2 conveyors are driven by 2 three-phase induction motors to transport cylindrical loads (bottles, PET bottles, etc.) between them (inverter is used for speed control)

- Application

- Printing and labeling on loads

Conventional Problems

- Heavy motors require stronger mounts, resulting in heavier and more expensive conveyors

Additionally, heavy conveyors make installation difficult

(Since 2 motors are used, the mass of the motors greatly affects the mass of the device.) - If the motor is heavy, you cannot lift it with one hand, making it difficult to work with

Solution

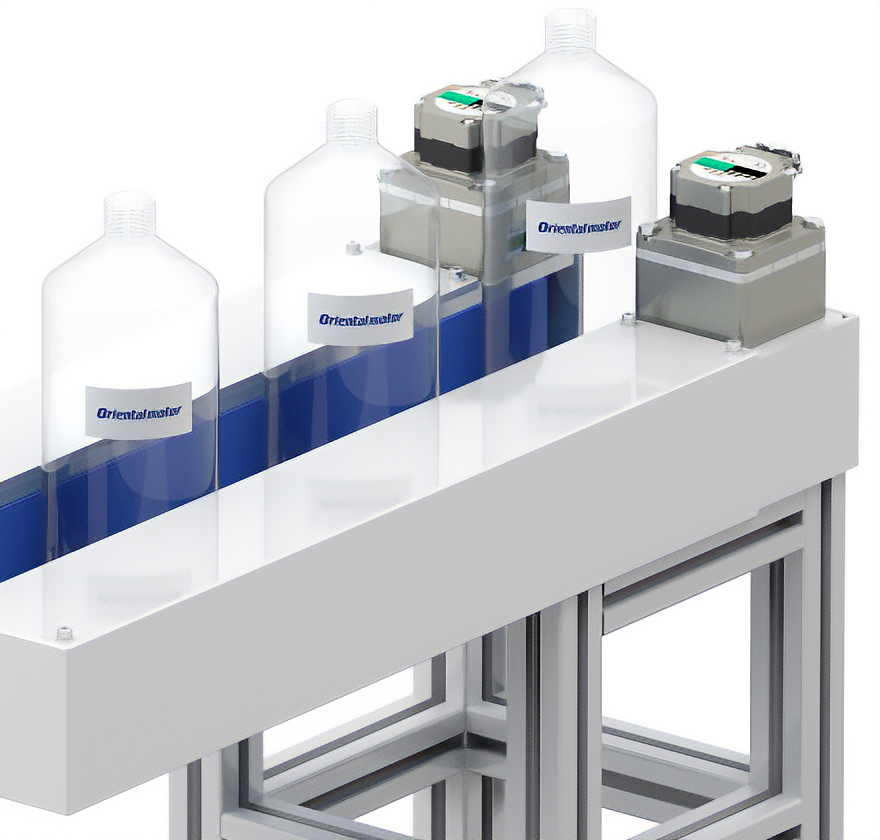

Brushless Motor BMU Series

Significant Weight Reduction of Motors

The Brushless Motor BMU Series is used to reduce the weight of the motors.

Specific Application Examples

Easy to Use, Affordable Conveyor

The lighter weight of the conveyor makes assembly, installation, and maintenance easier.

It also reduces the cost of equipment design because it increases the degree of freedom when designing the mounts.

Substantial Weight Reduction

By switching from three-phase induction motors to the BMU Series, the weight can be reduced by 6.6 kg (3.3 kg per unit).

| Oriental Motor Three-Phase Induction Motor (An example when combined with a general-purpose inverter) |

BMU Series | |

|---|---|---|

| Output Power | 90 W | 60 W |

| Frame Size | □90 mm | □80 mm |

| Gear type | Parallel Shaft | Parallel Shaft |

| Gear Ratio | 9 | 30 |

| Gearhead Output Shaft Permissible Torque |

4.2 N·m (33~133 r/min) | 5.2 N·m (2.7~66.7 r/min) 4.9 N·m (100 r/min) 3.7 N·m (133 r/min) |

| Mass | 4.7 kg | 1.4 kg 3.3 kg reduction |