Features and Advantages of αSTEP AZ Series Connector Type

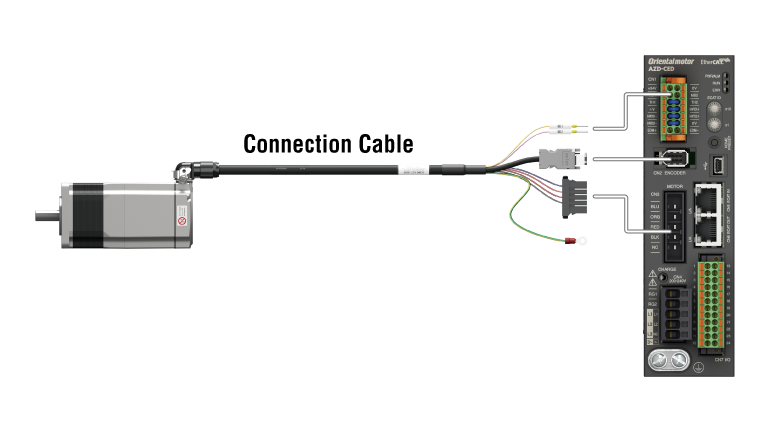

Direct Connection With Motors and Drivers

A connection of up to 10 m is possible without an extension cable. No extension cable is required.

The wiring process is more efficient as the power line, signal line, electromagnetic brake line, and ground wire all being consolidated into 1 cable.

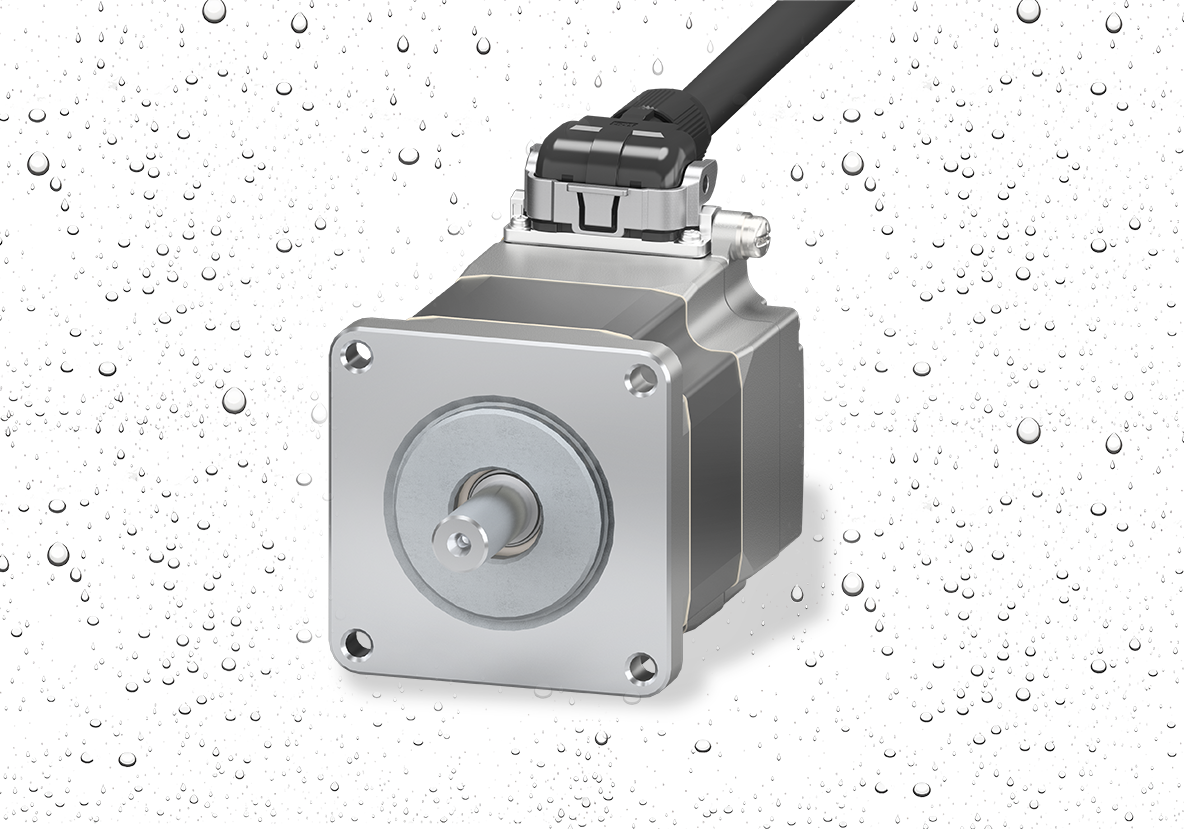

Connector Type (IP66 rating) for Usage in Wet Conditions

With a degree of protection IP66 rating, it has a high dust-resistant performance and can be used in wet conditions.

"Splash Resistant Test" Which Takes Into Account Deterioration Over TimeOriginal Evaluation of Oriental Motor

Motor installation location (indoors)

A place where water splashes. However, this excludes locations exposed to oil and chemicals, underwater, and areas with high water pressure.

Our unique "Splash Resistant Test"

The following tests are conducted in this order: ① thermal shock test, ② vibration test, and ③ water jet test to confirm that no water intrusion occurs.

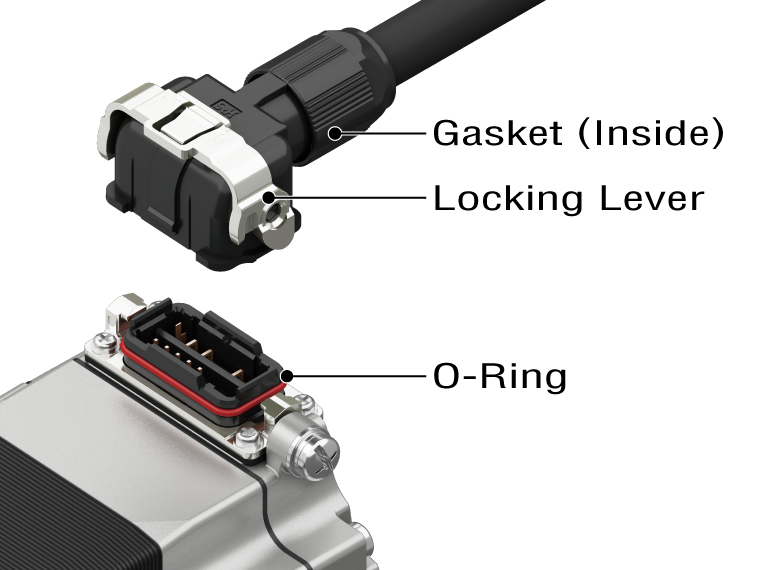

Connector Structure

The connector structure has a built-in gasket and O-ring for improved waterproofing. It is IP66-compliant, including the connector part.

Locking Lever Connector is Used for Simple Connection

Cable connection is easy due to the locking lever that does not require screw fitting.

3 Cable Outlet Directions Can be Selected

3 cable outlet directions can be selected. It improves the flexibility of cable routing around the motor.

-

Cable Outlet in Output Shaft Direction -

Cable Outlet in Vertical Direction -

Cable Outlet Opposite to Output Shaft Direction

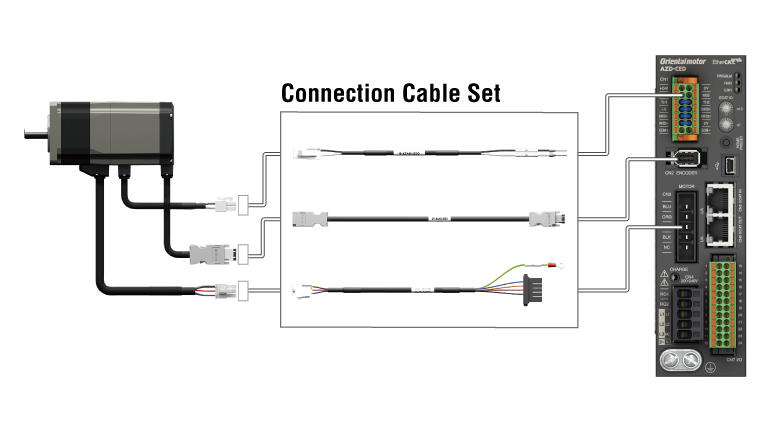

Use of a Single Cable Reduces the Time Required for Routing and the Cable Holder Size

-

Conventional Product (Cable type)

Z-Axis (Electromagnetic brake motor): 3 cables

Y-Axis (Standard motor): 2 cables

-

Connector Type

Z-Axis (Electromagnetic brake motor): 1 cable

Y-Axis (Standard motor): 1 cable

Direct Connection Reduces the Motor and Cable Replacement Time

-

Conventional Product (Cable type)

-

Connector Type

Reference: Comparison of Connection Cable Diameters, Cross-Sectional Areas, and Masses

For the electromagnetic brake motor, flexible connection cable, with length of 5 m

-

Cable Type

-

Connector Type

| Cable Type (3 cables*) |

Connector Type (1 cable) |

|||

|---|---|---|---|---|

| Diameter [mm] | ・ φ8 for Motor ・ φ6 for Electromagnetic Brake ・ φ8 for Encoder |

φ8.9 | ||

| Cross-Sectional Area [mm2] | 111.7 | ➜ 44.3 % reduction |

62.2 | |

| Mass [kg] | 1.19 | ➜ 55.5 % reduction |

0.53 | |

- *3 cables, 1 for motor, 1 for encoder, and 1 for electromagnetic brake